Measuring method for track errors of robot

A measurement method and robot technology, applied in the direction of manipulators, program-controlled manipulators, manufacturing tools, etc., can solve problems such as narrow application fields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

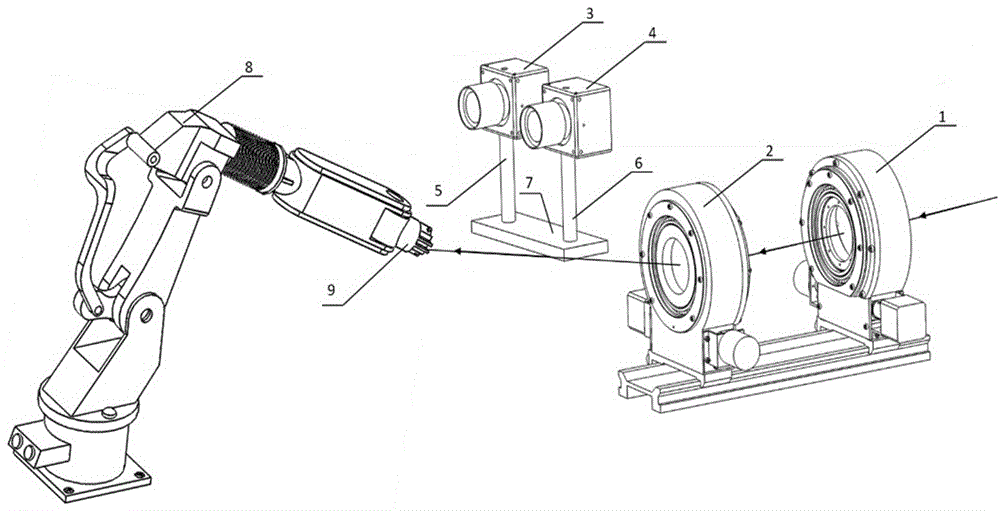

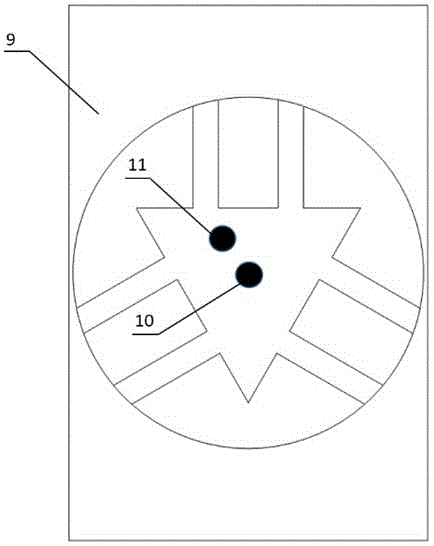

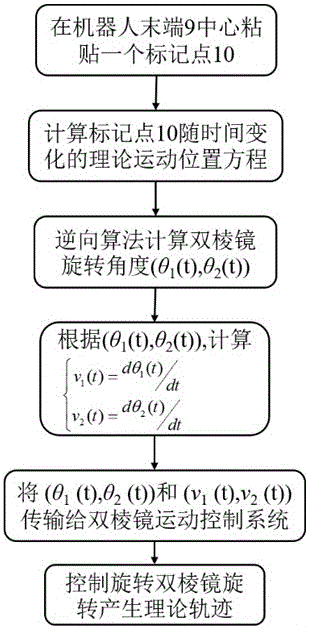

[0053] The invention provides a method for measuring robot trajectory error, which can realize the measurement of the robot's full-range or local maximum motion error: during the robot's motion process, the actual motion trajectory of the robot end is collected in real time through the visual imaging system throughout the entire process, and at the same time, the trajectory generator generates the motion of the robot. Theoretical trajectory, by comparing the two trajectories, the maximum motion error of the robot in a certain period of time or in the whole process can be obtained.

[0054] 2. The object of the present invention is achieved through the following parts: a binocular vision measurement system comprising a rotating double prism system for a trajectory generator and trajectory image acquisition. According to the theoretical motion trajectory of the robot, the rotating double prism produces a high-precision beam scanning trajectory that is irradiated on the end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com