Novel hook cutter combination structure and method for napping and cutting loop with same

A combined structure and hook knife technology, applied in textiles and papermaking, weft knitting, knitting, etc., can solve the problems of unstable debugging, high position requirements, and high requirements for debugging personnel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

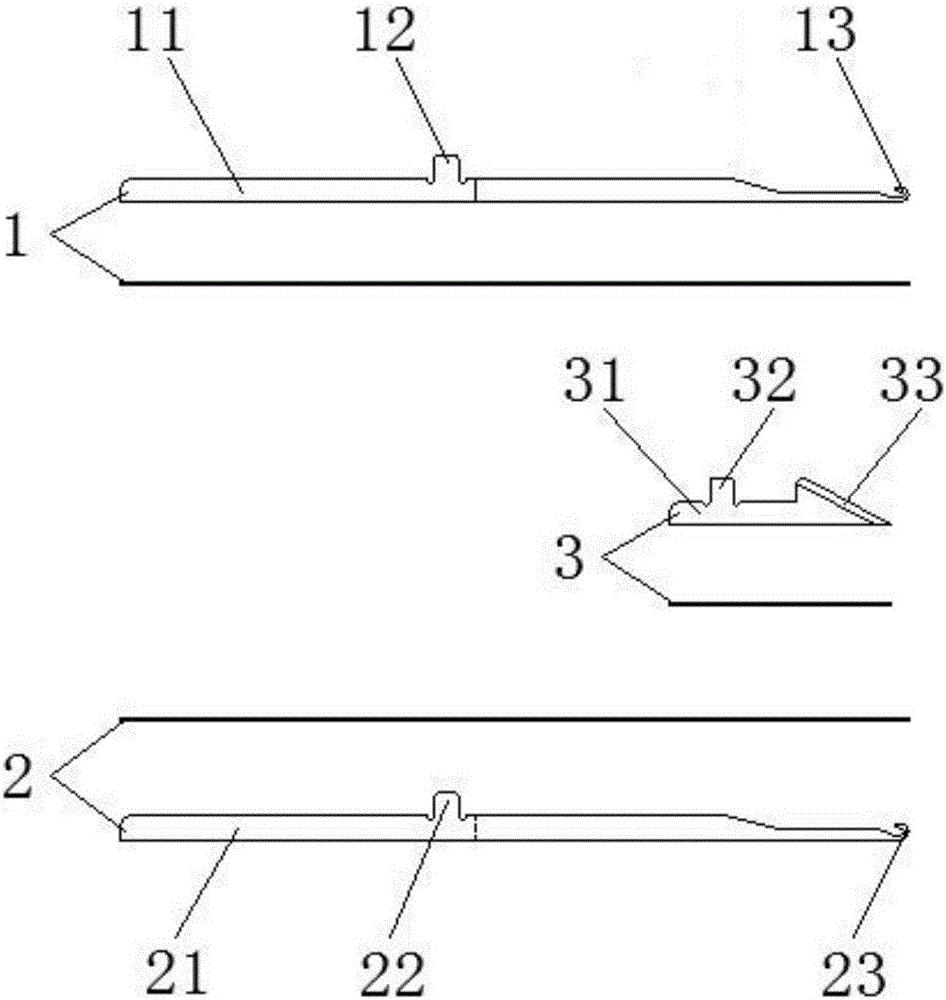

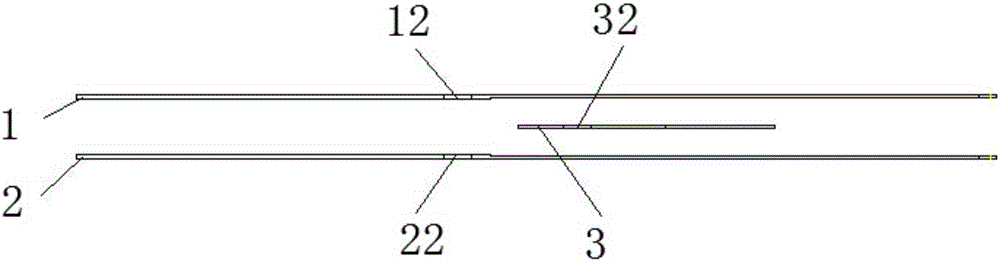

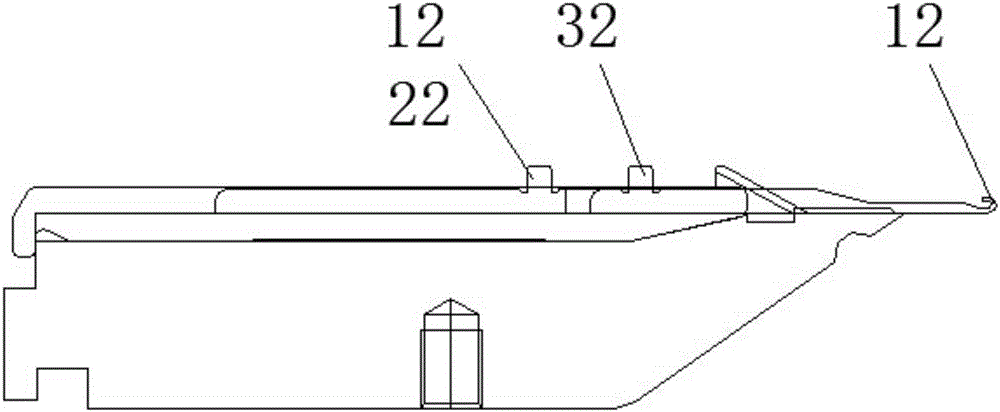

[0020] refer to figure 1 , a new type of hook-knife combination structure, which is composed of three parts: left hook 1, right hook 2 and cutter 3. The left hook 1, right hook 2 and cutter 3 are placed on the same needle On the groove, the left hook 1 and the right hook 3 are symmetrically arranged on both sides of the cutter 3, and the left hook 1, the right hook 2 and the cutter 3 each have a matching independent triangular assembly. Left crochet bar 11, left crochet pin 12, left crochet hook 13 are provided, right hook 2 is provided with right crochet bar 21, right crochet pin 22, right crochet hook 23, the left crochet of described left hook 1 and right hook 2 The pin 13 and the right hook pin 23 are in the same position, and the cutting knife 3 is provided with a needle bar 31 , a pin 32 and a knife edge 33 .

[0021] A kind of method that adopts above-mentioned novel hook-knife combined structure to nap and cut circle, method is as follows:

[0022] Such as figure 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com