An eddy current probe ring array method for detecting the layup direction of carbon fiber composites

An eddy current probe and annular array technology, applied in the direction of material magnetic variables, can solve the problems of detection sensitivity, distance change, measurement error, etc., and achieve the effects of shortening detection time, avoiding measurement error, and eliminating mechanical rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

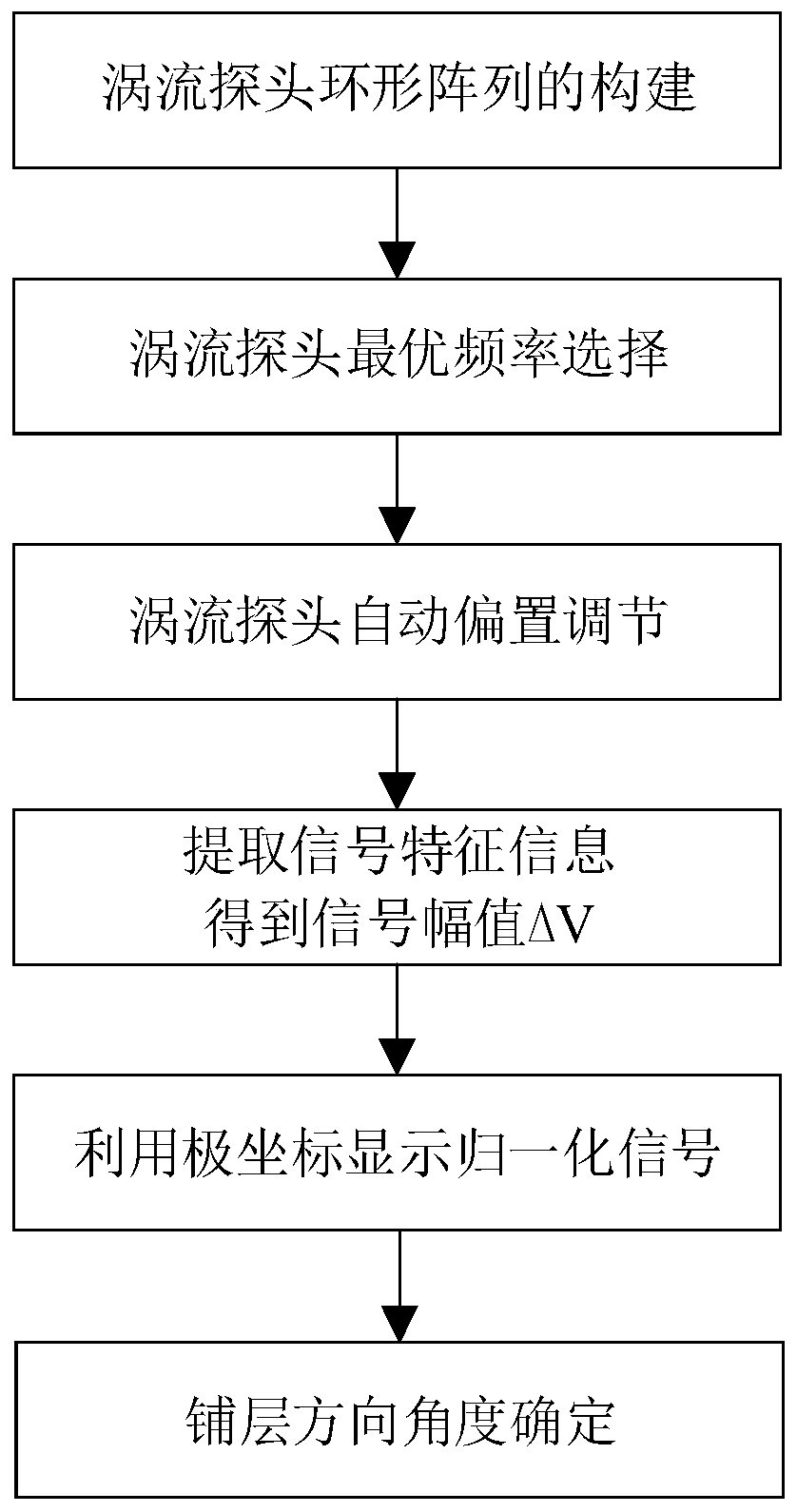

[0027] The solution of the present invention will be described in detail below in conjunction with the accompanying drawings. The following examples are carried out on the premise of the technical solution of the present invention, and specific implementation schemes and operation processes are provided, but the protection scope of the present invention is not limited to the following examples.

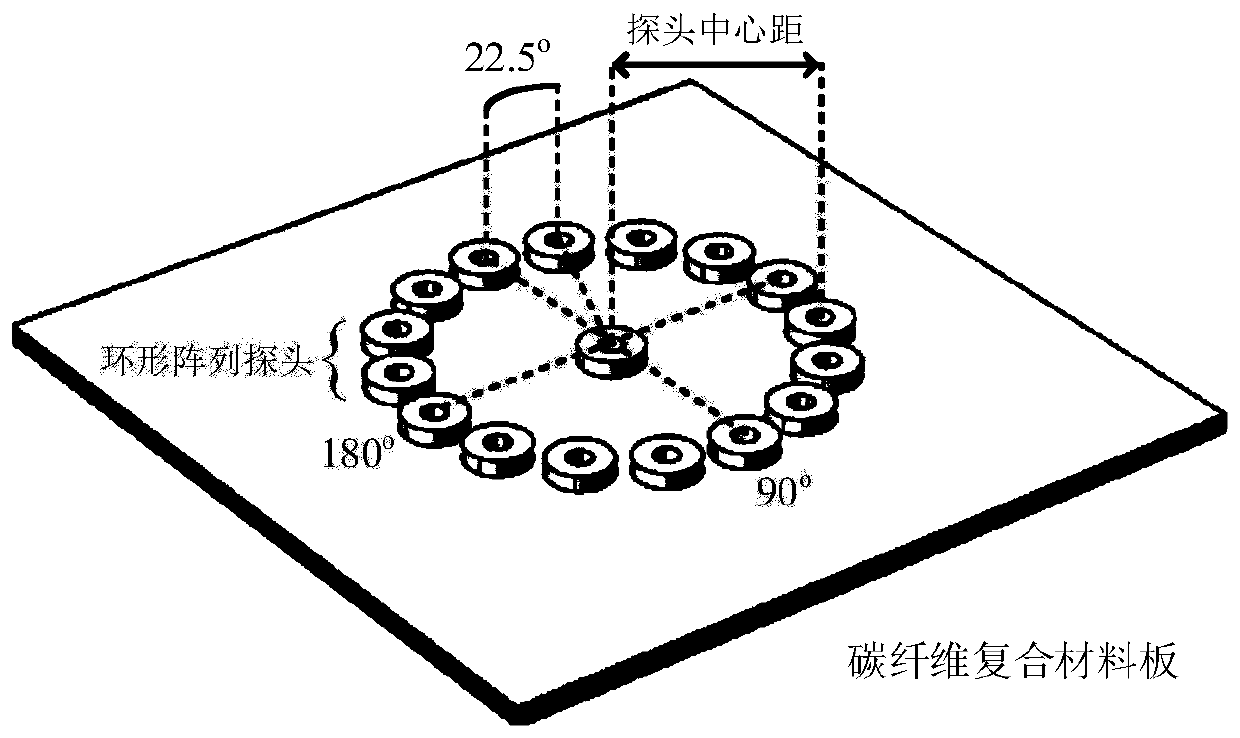

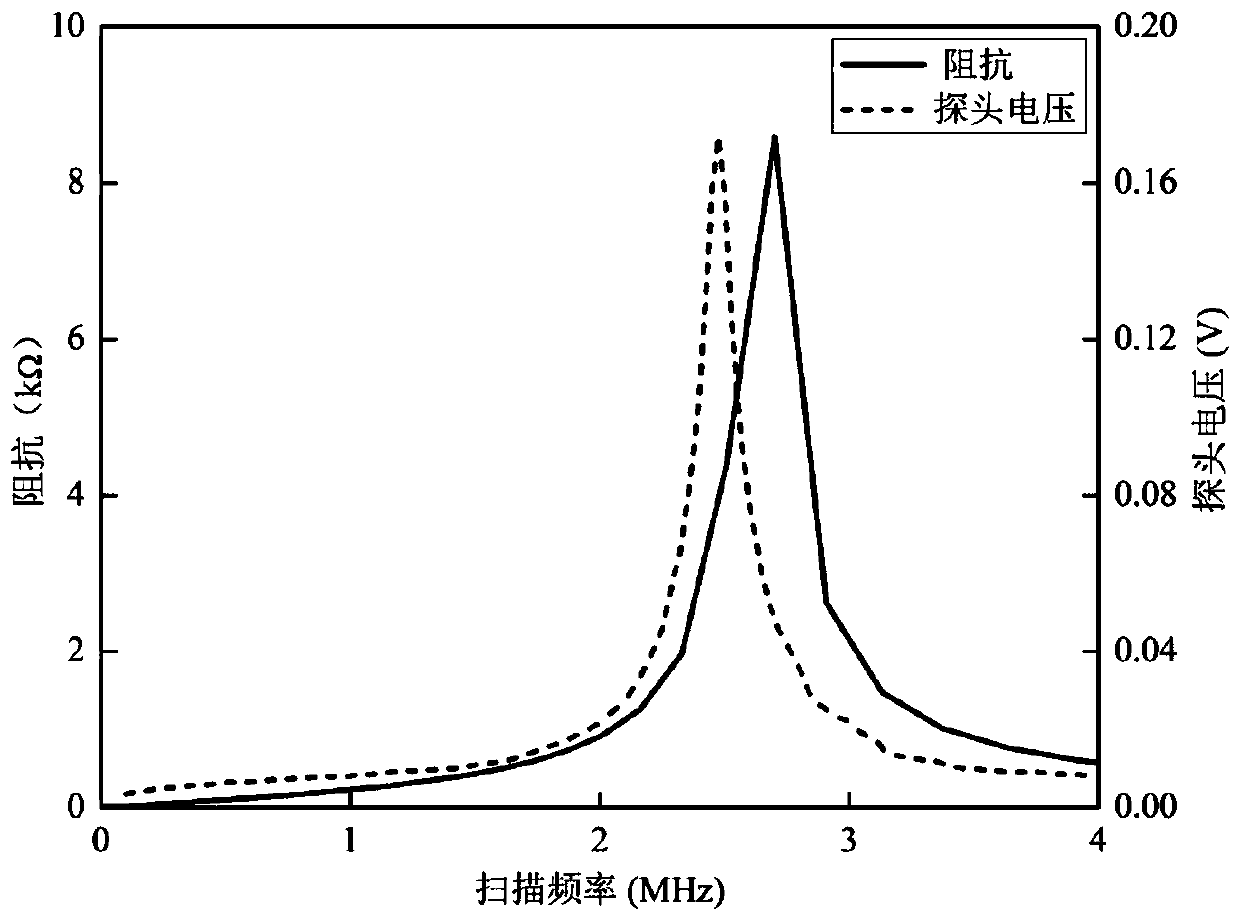

[0028] Step 1: Construct a circular array of eddy current probes. Arrange the eddy current probes evenly in the structure in a circular manner, and ensure that the eddy current probes cover the entire area of the project structure to be tested. The eddy current probes are transmitting-receiving probes, and adopt one transmitting and multiple receiving methods. The position of each receiving probe must be kept with the transmitting probe. A certain distance is used to avoid the influence of the eddy current overlap near the transmitting coil on the signal of the receiving coil. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com