Slide rail assembly

A technology of slide rail assembly and retaining parts, which is applied in the direction of rack/frame structure, furniture parts, household appliances, etc., and can solve the problems of inconvenient maintenance and operation of the chassis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

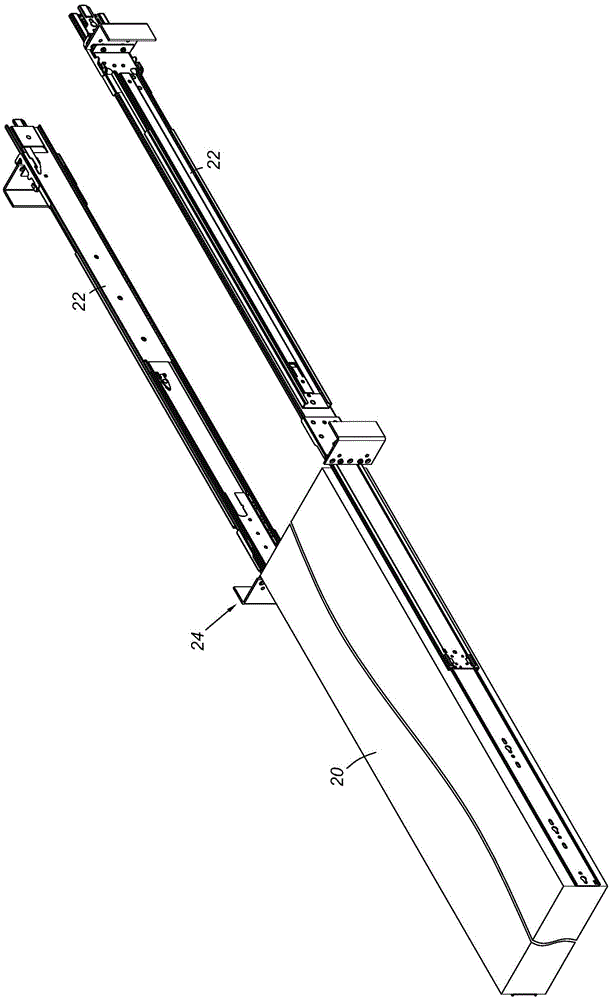

[0029] figure 1 A chassis (chassis) 20 showing an embodiment of the present invention is mounted to a rack (rack) 24 by means of a pair of slide rail assemblies 22, and the opening stroke length of the slide rail assembly 22 is fully expanded so that the chassis 20 The pair of slide rail assemblies 22 can be completely displaced outside the frame 24 .

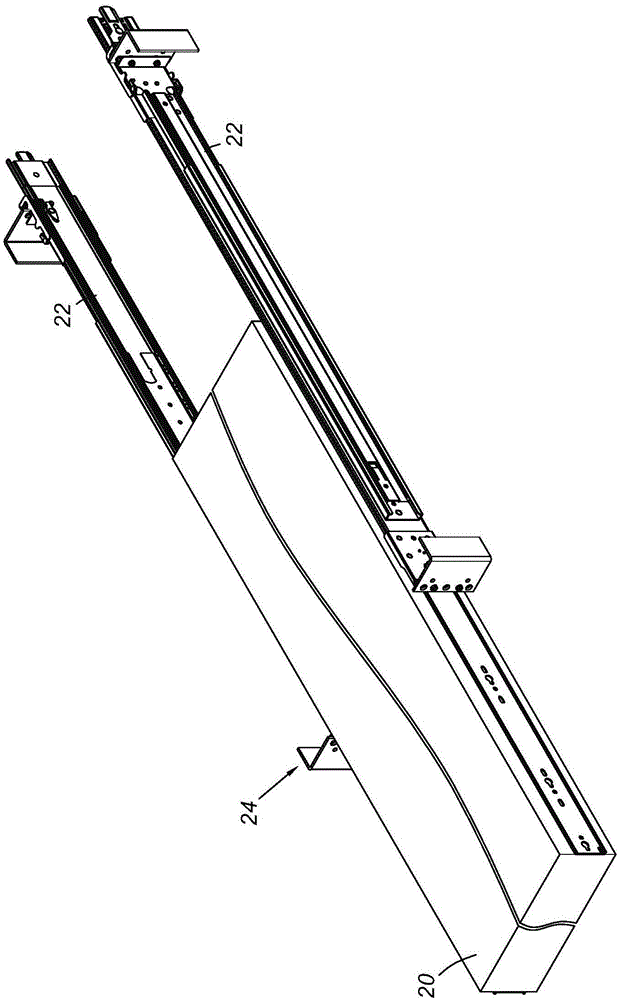

[0030] figure 2 It shows that the length of the opening stroke of the embodiment of the present invention is adjusted and shortened through the slide rail assembly 22, so that the chassis 20 can only be displaced to a part outside the frame 24, compared to figure 1 The operating mode only occupies a small opening space.

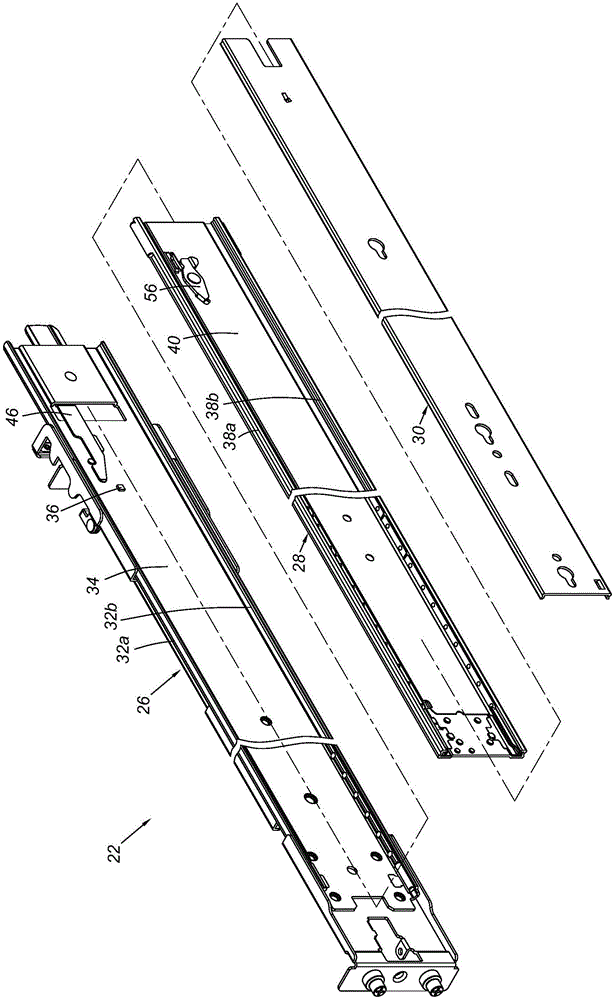

[0031] image 3 The slide rail assembly 22 illustrating an embodiment of the present invention includes a first rail 26 , a second rail 28 and a third rail 30 . Wherein, the first rail 26 has a first upper wall 32a, a first lower wall 32b, and a first side wall 34 connected between the first upper wall 32...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com