Multi-angle rotatable stepped goods transferring and conveying equipment

A transfer conveying, stepped technology, applied in the direction of conveyor, conveyor objects, transportation and packaging, etc., can solve the problem of difficult manual control at the end of the conveying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

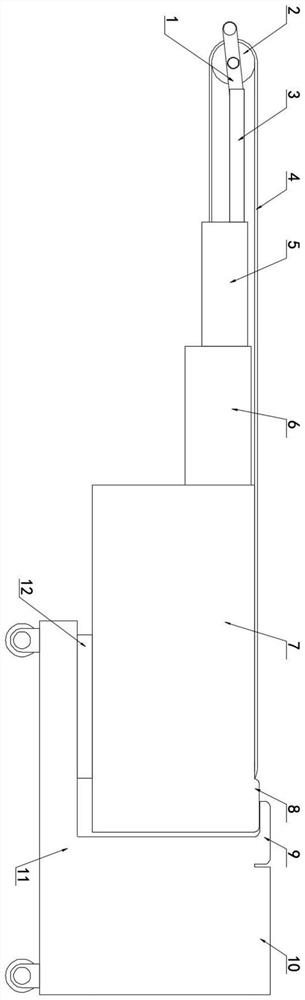

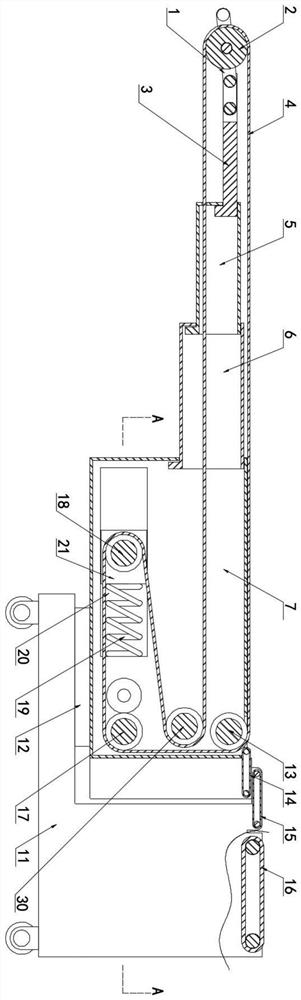

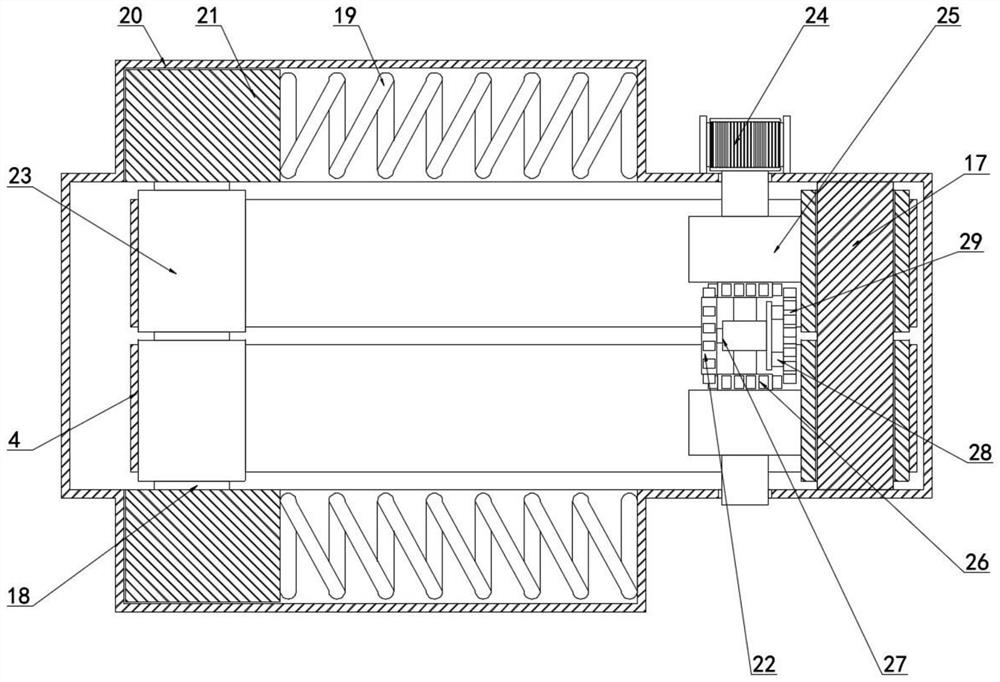

[0032] Example 1, please refer to Figure 1-3, the present invention provides a technical solution: a multi-angle rotatable ladder-type cargo transfer and conveying equipment, including a base 11 and a fourth carriage 7 arranged above the base 11, and a rotating disc 12 is fixed on the base 11 , the fourth carriage 7 is rotationally connected with the rotating disk 12, the fourth carriage 7 is slidably connected to the opening at one end of the base 11, and the third carriage 6 is slidably connected to the opening at one end of the fourth carriage 7 away from the fourth carriage 7 The second slide frame 5 is slidably connected, the first slide frame 3 is slidably connected to the opening of the second slide frame 5 away from the third slide frame 6, and the end of the first slide frame 3 away from the second slide frame 5 is fixed with a manual The pull rod arm 1 is rotatably connected with two first external transmission rollers 2 on the manual pull rod arm 1, the third trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com