Patents

Literature

31results about How to "Adjust cooling effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

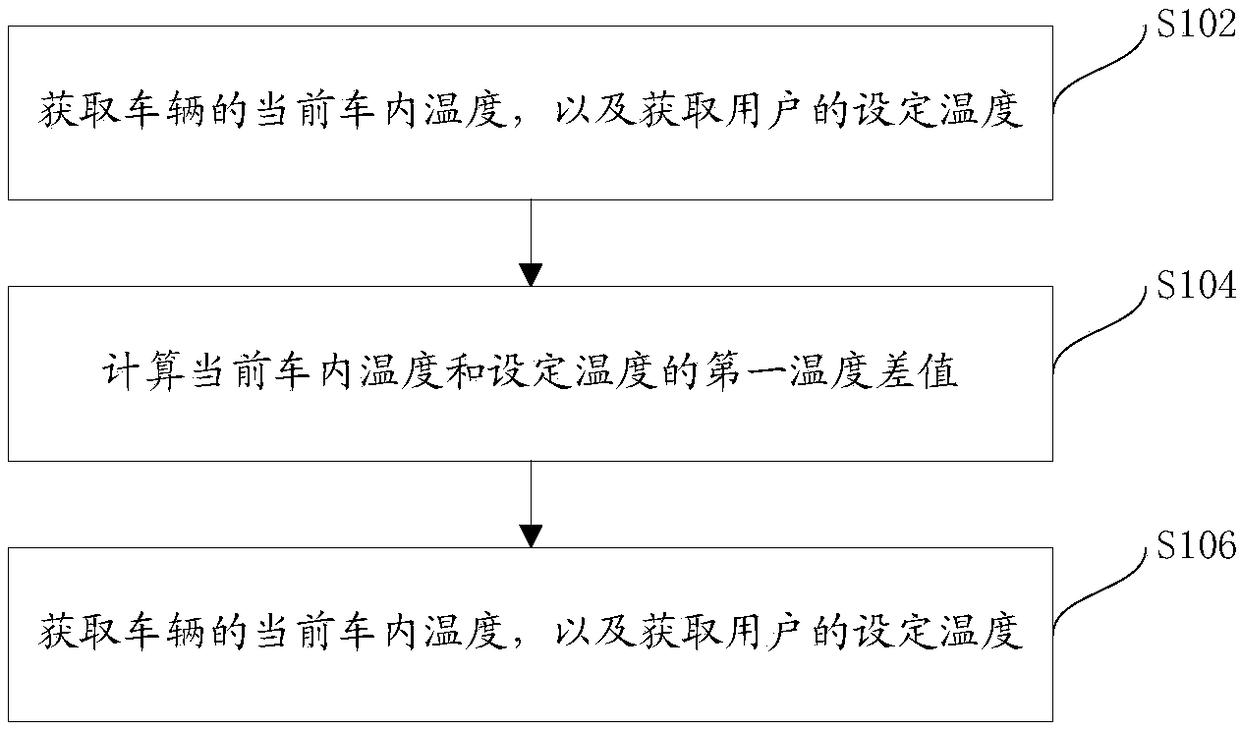

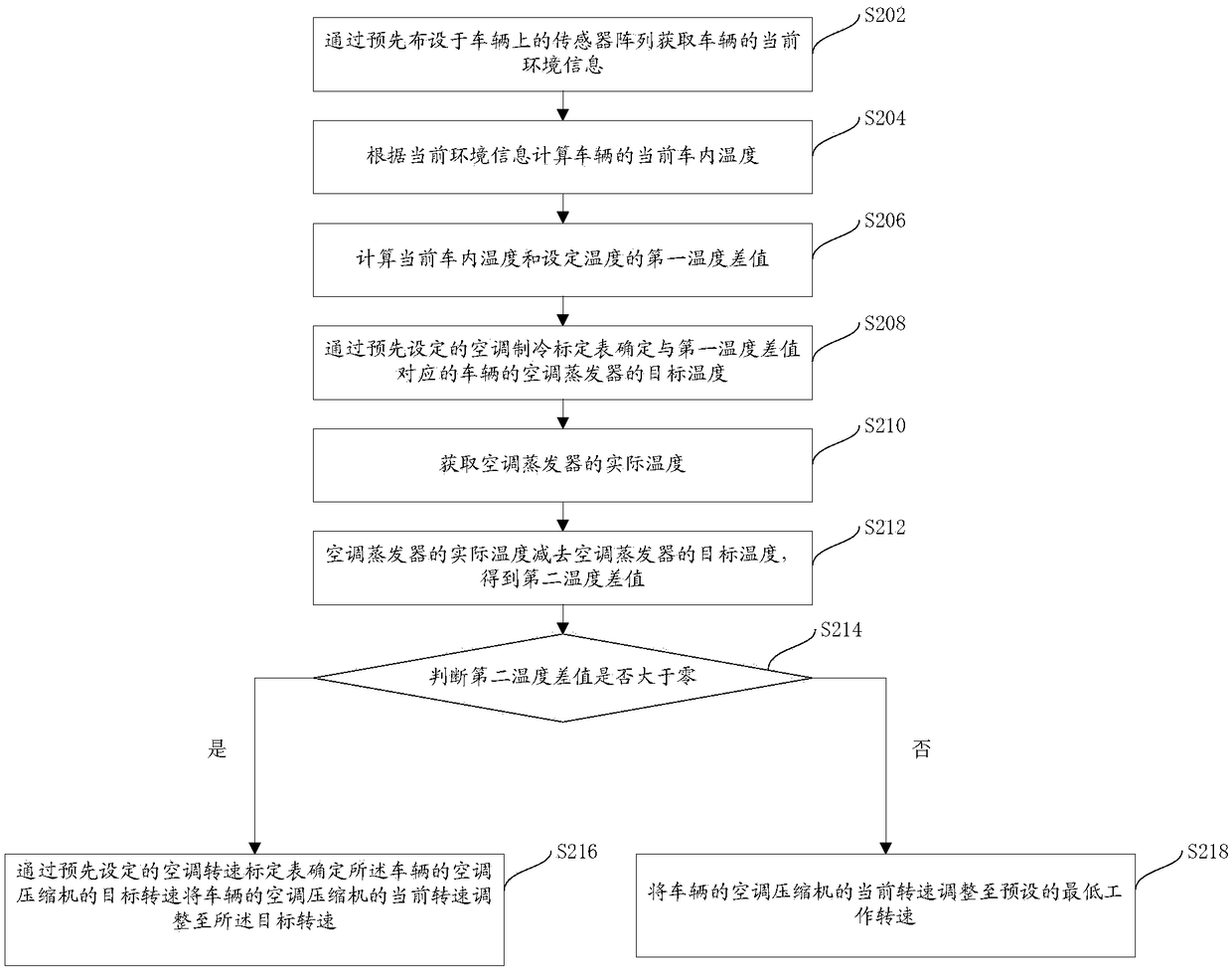

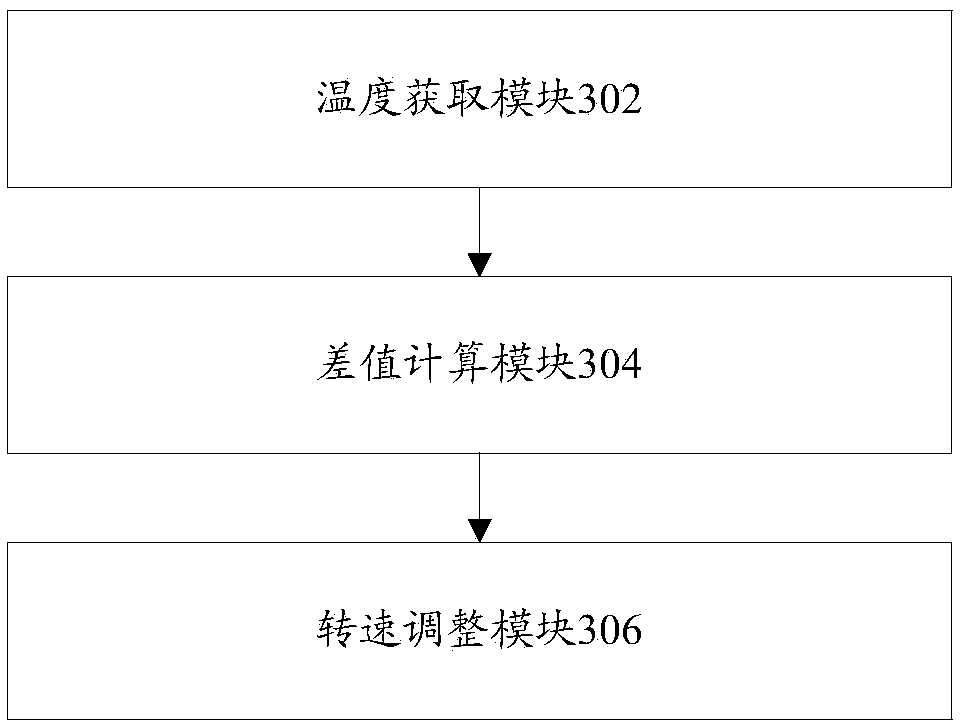

Rotational speed control method, device and electronic device for air conditioning compressor

InactiveCN109017218AAdjust cooling effectImprove driving comfortAir-treating devicesVehicle heating/cooling devicesElectric equipmentRefrigeration

The invention provides a rotational speed control method, a device and an electronic device of an air conditioning compressor, which relate to the technical field of compressor rotational speed control. The method is applied to a vehicle. Calculating a first temperature difference between a current vehicle interior temperature and a set temperature; The rotational speed of the air conditioning compressor of the vehicle is adjusted according to the first temperature difference. The invention can automatically adjust the rotational speed of the air conditioning compressor of the vehicle by judging the difference between the set temperature of the user and the actual temperature in the vehicle, thereby helping to adjust the refrigeration effect of the air conditioning and improving the driving comfort of the user.

Owner:重庆超力电器有限责任公司

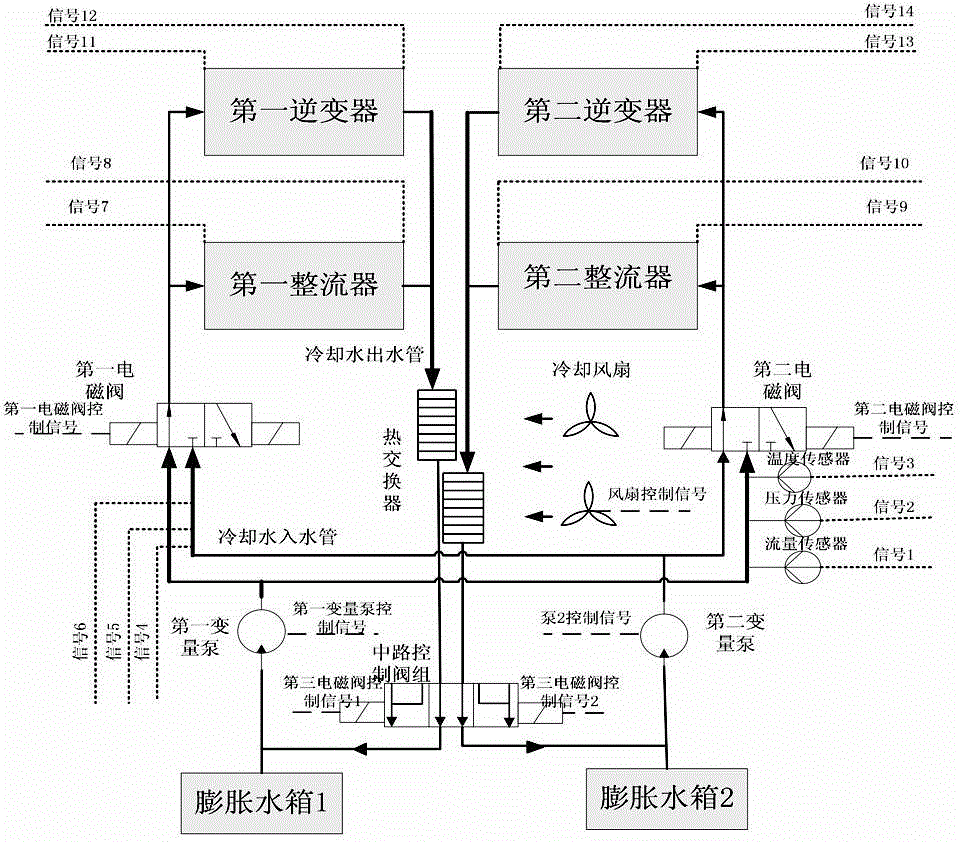

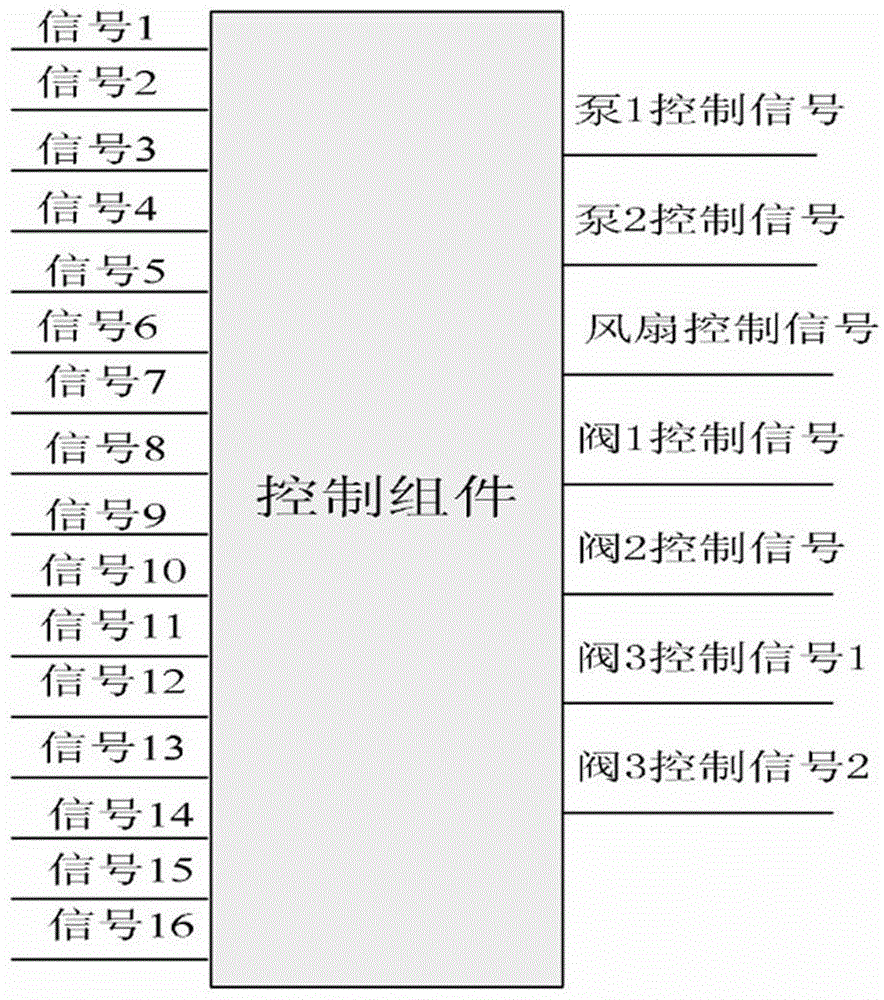

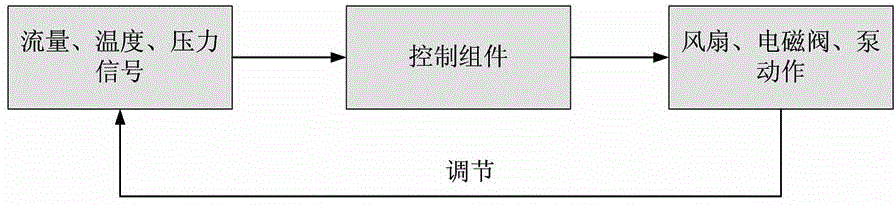

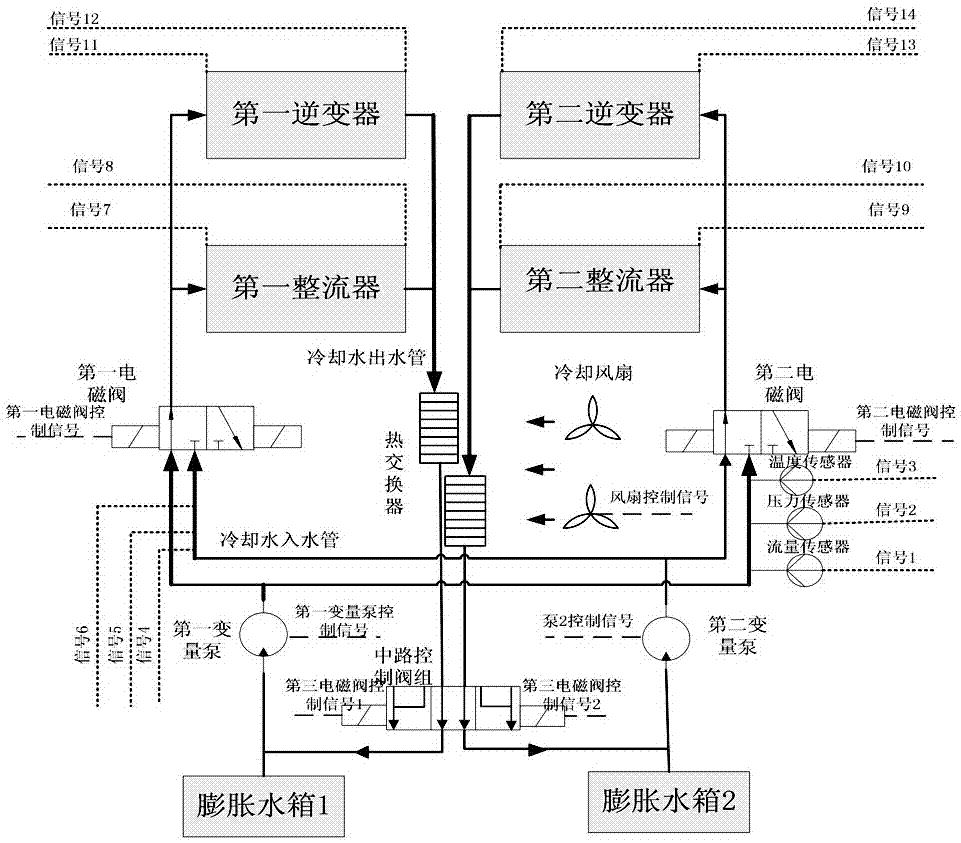

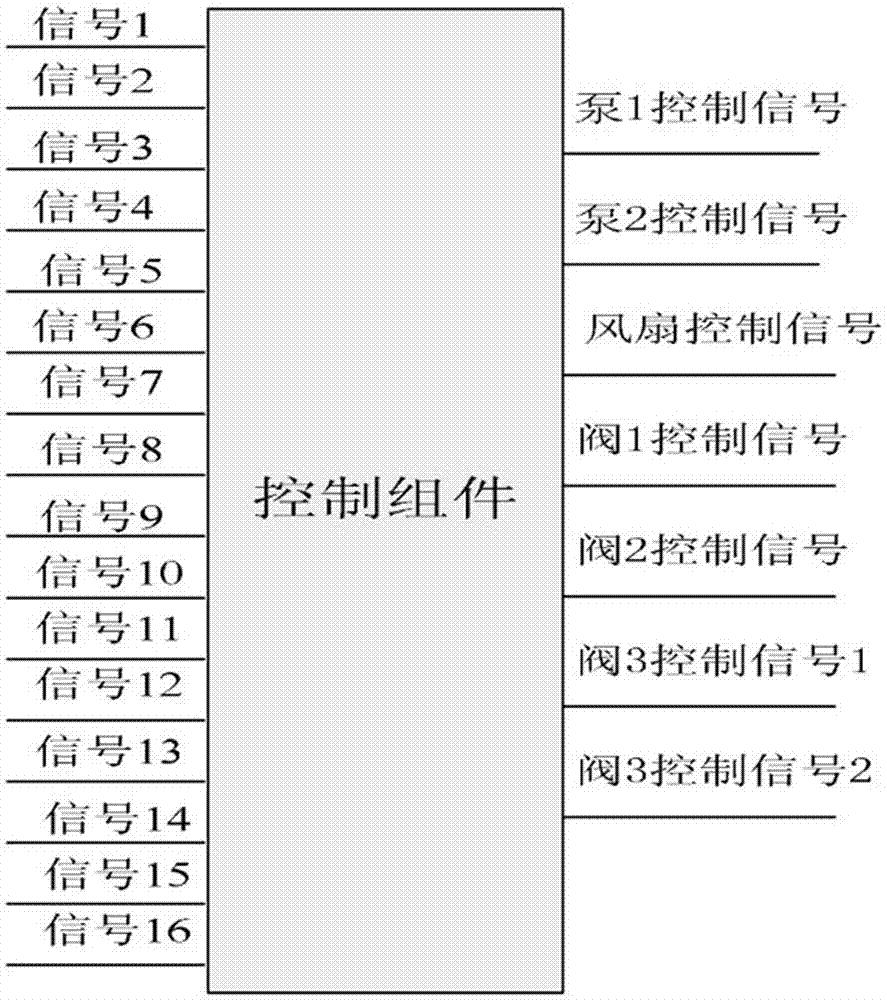

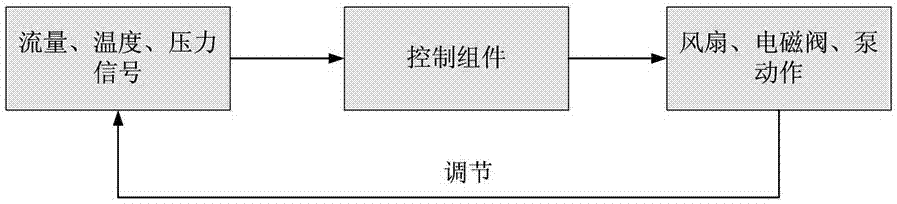

Intelligent converter cooling system and intelligent cooling control method

ActiveCN104901557AReduce external noise pollutionAdjust cooling effectAc-dc conversionCooling/ventilation/heating modificationsSolenoid valveCooling effect

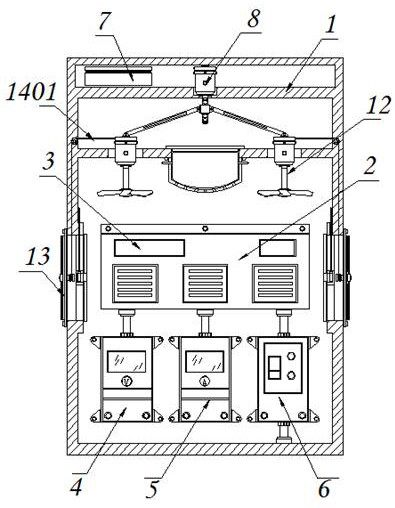

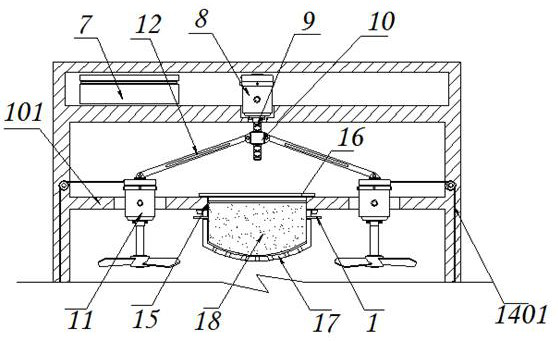

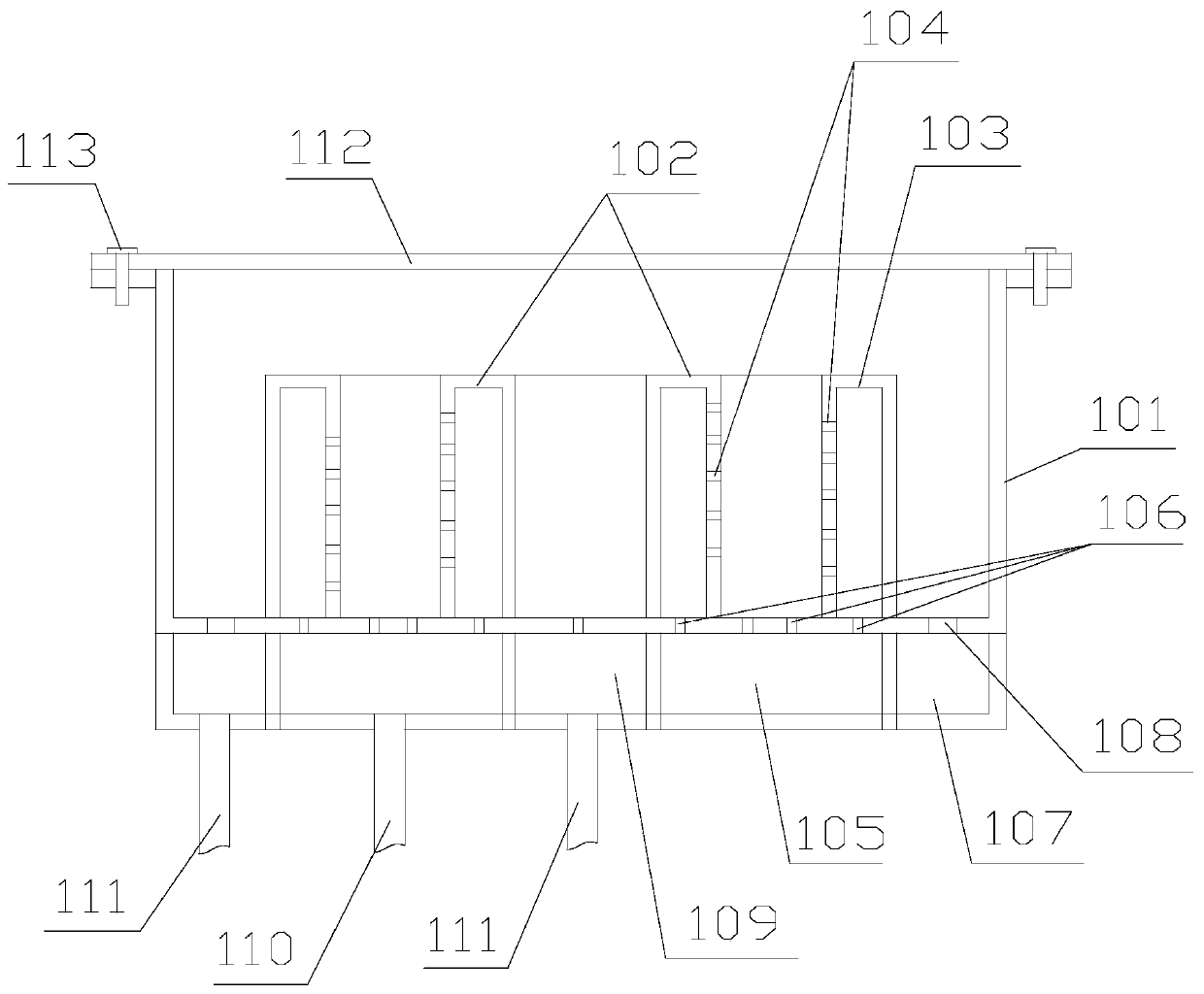

The invention discloses an intelligent converter cooling system and an intelligent cooling control method. A first cooling loop in the system comprises a first variable pump, a first cooling pipe, a first cooling medium box, a first electromagnetic wave and a first heat exchanger which flow through a first inverter and a first rectifier and form the loop via pipes; a second cooling loop comprises a second variable pump, a second cooling pipe, a second cooling medium box, a second electromagnetic wave and a second heat exchanger which flow through a second inverter and a second rectifier and form the loop via pipes; both the first cooling loop and the second cooling loop flow through a middle control valve group; and a control assembly controls the middle control valve group via monitoring signals of a sensor assembly, to switch the working states of the first cooling loop and / or the second cooling loop. The method is executed on the basis of the system. The system and the method have the advantages of simple principle, good cooling effect and energy-saving effect and the like.

Owner:ZHUZHOU CSR TIMES ELECTRIC CO LTD

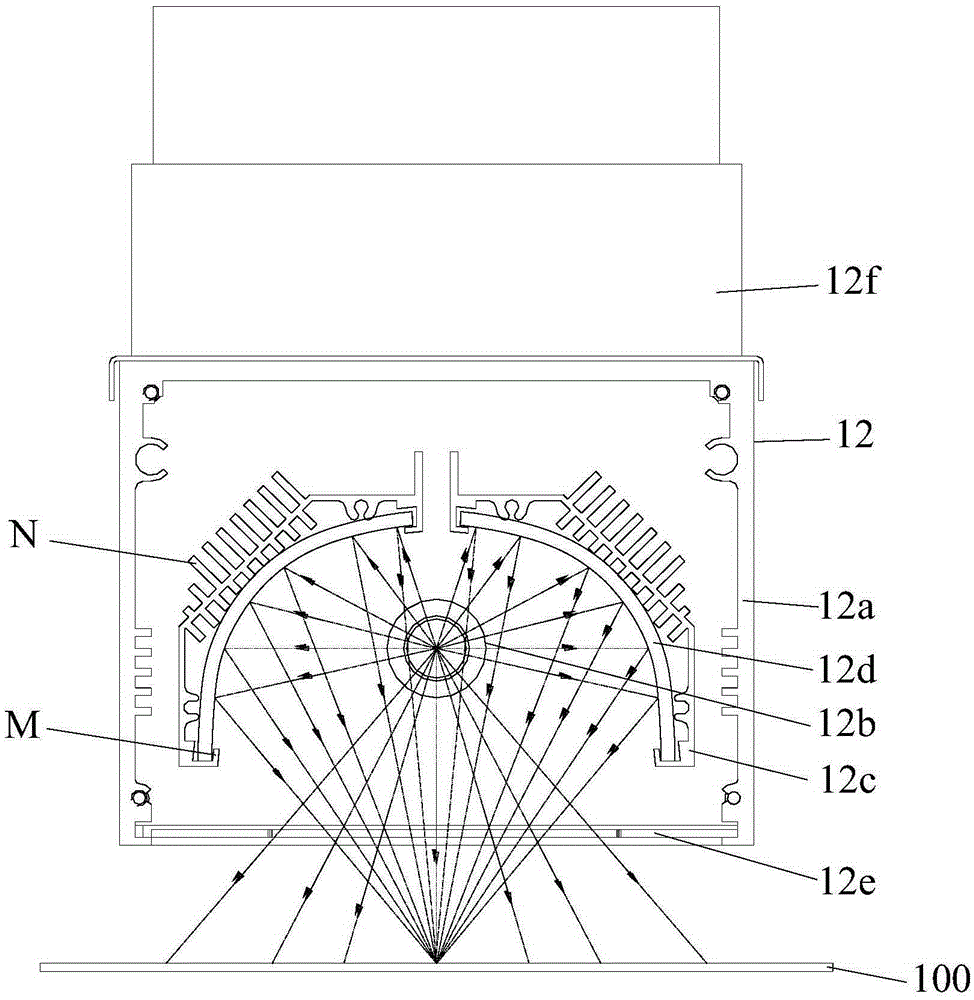

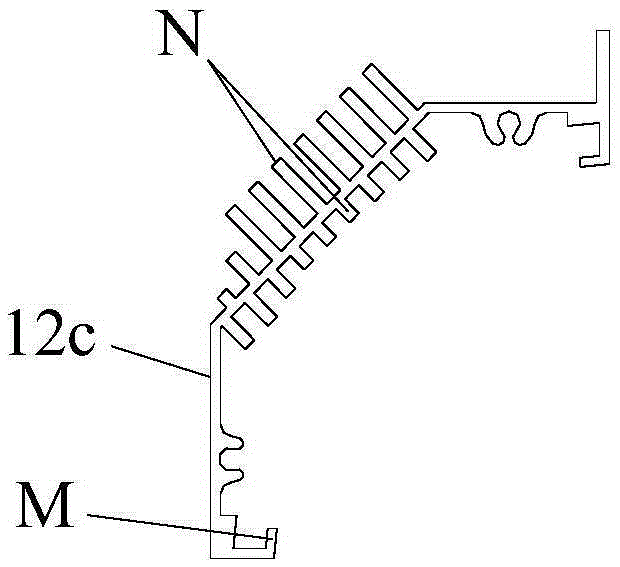

Ultraviolet drying machine having cooling function and cooling control method

The invention discloses an ultraviolet drying machine having a cooling function. The ultraviolet drying machine comprises a stand, wherein a UV curing channel arranged in the stand in the longitudinal direction; multiple UV lamp sets are spaced in the UV curing channel; each UV lamp set comprises a lamp cover fixed on the top wall of the UV curing channel and a UV lamp tube arranged in the lamp cover; fixed frames capable of absorbing infrared rays, curved quartz glass capable of penetrating through the infrared rays and reflecting ultraviolet rays and plane quartz glass capable of penetrating through the ultraviolet rays and reflecting the infrared rays are arranged in the lamp covers; the curved surface quartz glass and the fixed frames are positioned at the upper sides of the UV lamp tubes in sequence; the curved quartz glass is fixed on the fixed frames; and the plane quartz glass is positioned at the lower sides of the UV lamp tubes. The invention further discloses a cooling control method. The ultraviolet drying machine having the cooling function and the cooling control method can effectively reduce the temperature in the glue UV curing process, and guarantee the product quality.

Owner:ZHISHENG SCI & TECH GUANGZHOU

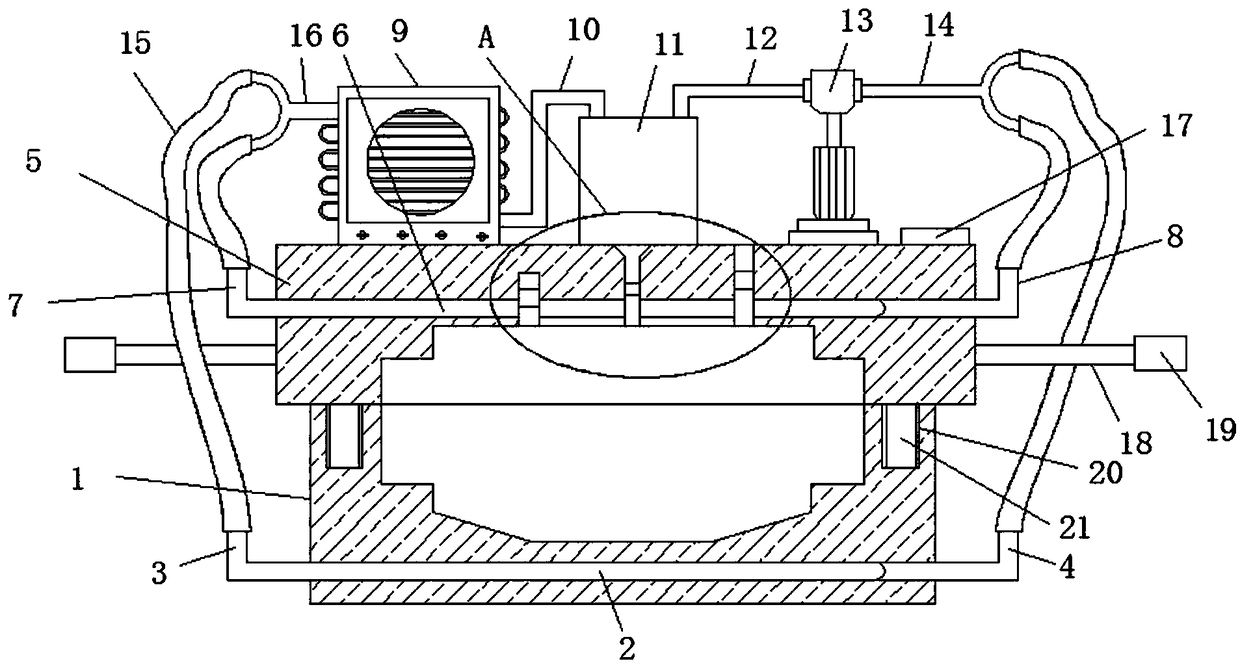

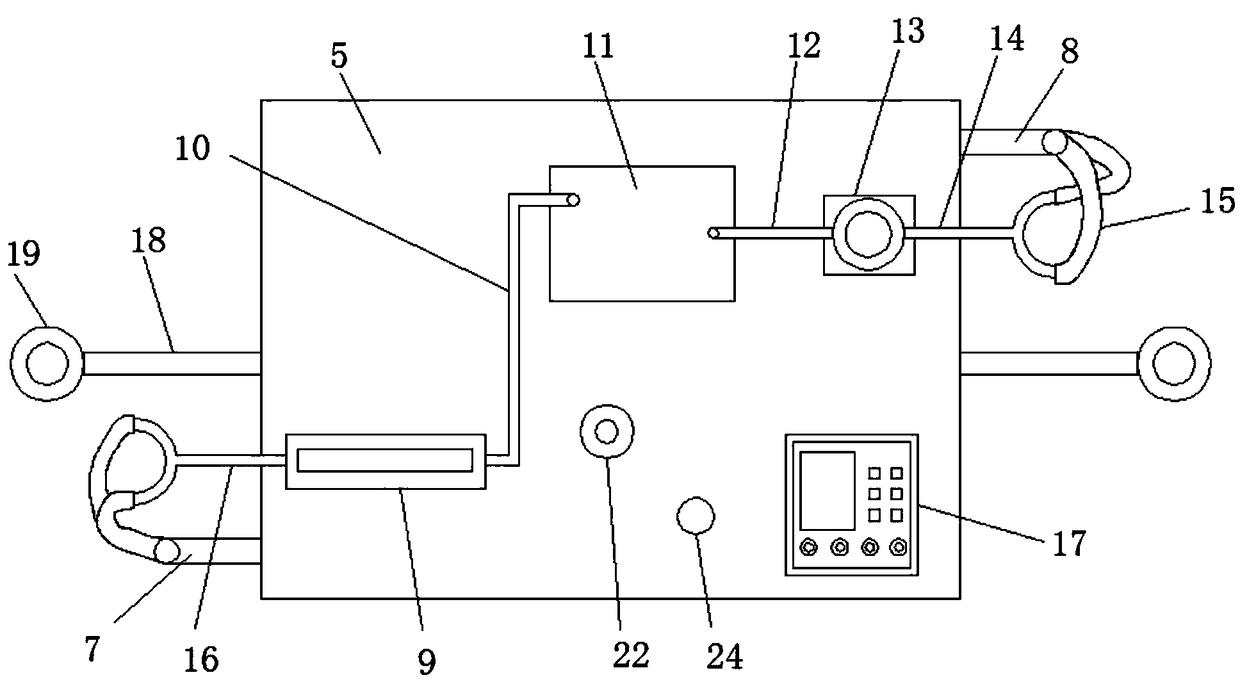

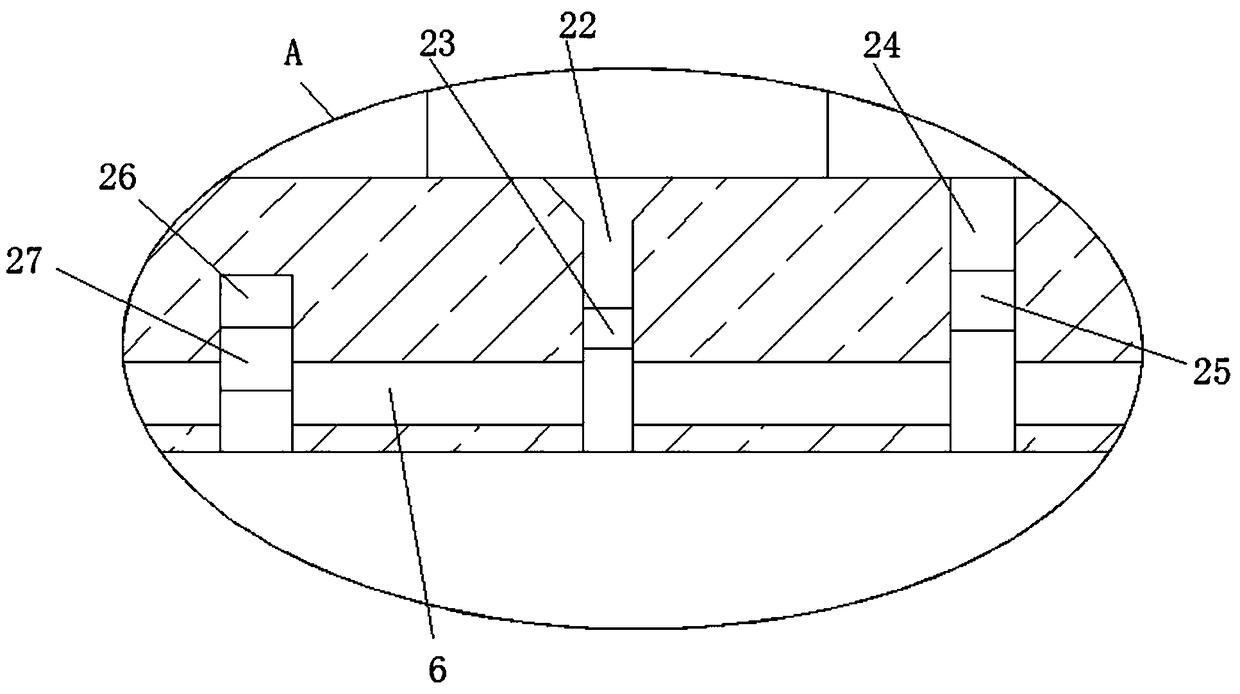

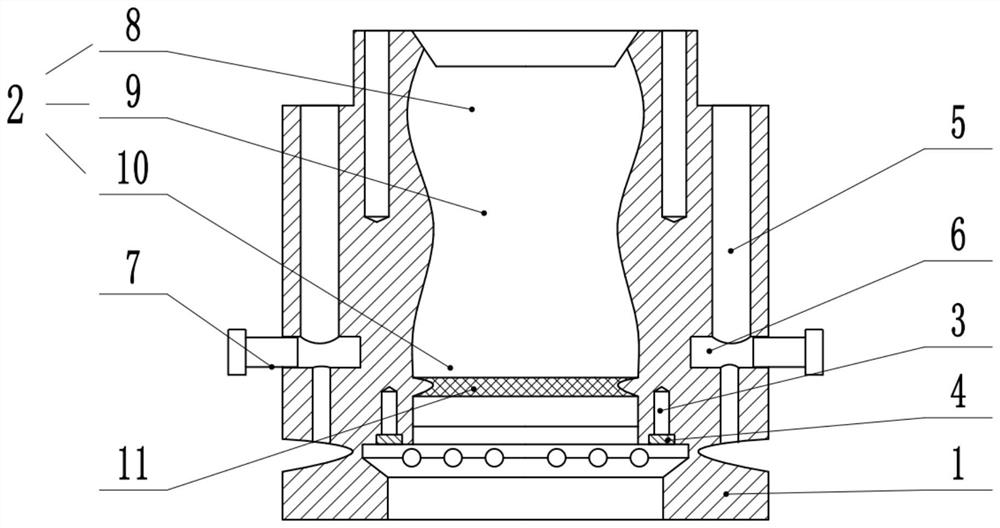

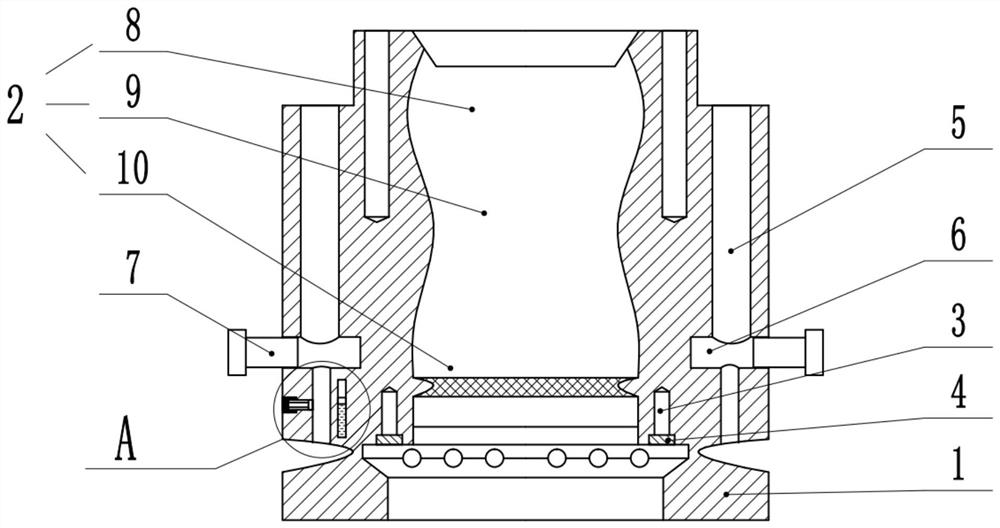

Automobile injection molded part cooling device

The invention belongs to the technical field of automobile manufacturing and particularly relates to an automobile injection molded part cooling device. The device comprises a lower mould body, a lower cooling pipe is arranged on the lower mould body, and a first liquid inlet and a first liquid outlet are formed in the two ends of the lower cooling pipe correspondingly and extend to the outside ofthe lower mould body; an upper mould body is arranged on the top side of the lower mould body and matched with the lower mould body, an upper cooling pipe is arranged on the upper mould body, and a second liquid inlet and a second liquid outlet are formed in the two ends of the upper cooling pipe correspondingly and extend to the outside of the upper mould body; and a condenser, a reservoir and avariable frequency pump are fixedly mounted on the top side of the upper mould body, and a first flow splitting pipe is mounted in a water inlet of the condenser and connected with the first liquid outlet and the second liquid outlet through leather hoses correspondingly. According to the cooling device, injection molded parts are convenient to cool, the cooling effect is good, data including thetemperature, the pressure, the flow rate and the like are convenient to observe in real time, and the product quality can be better controlled.

Owner:岳西县同兴尼龙橡胶制品有限公司

Intelligent power utilization safety supervision system based on Internet of Things technology

PendingCN113972581ASmall apertureExpanded via hole diameterDispersed particle filtrationTransportation and packagingDistribution controlThe Internet

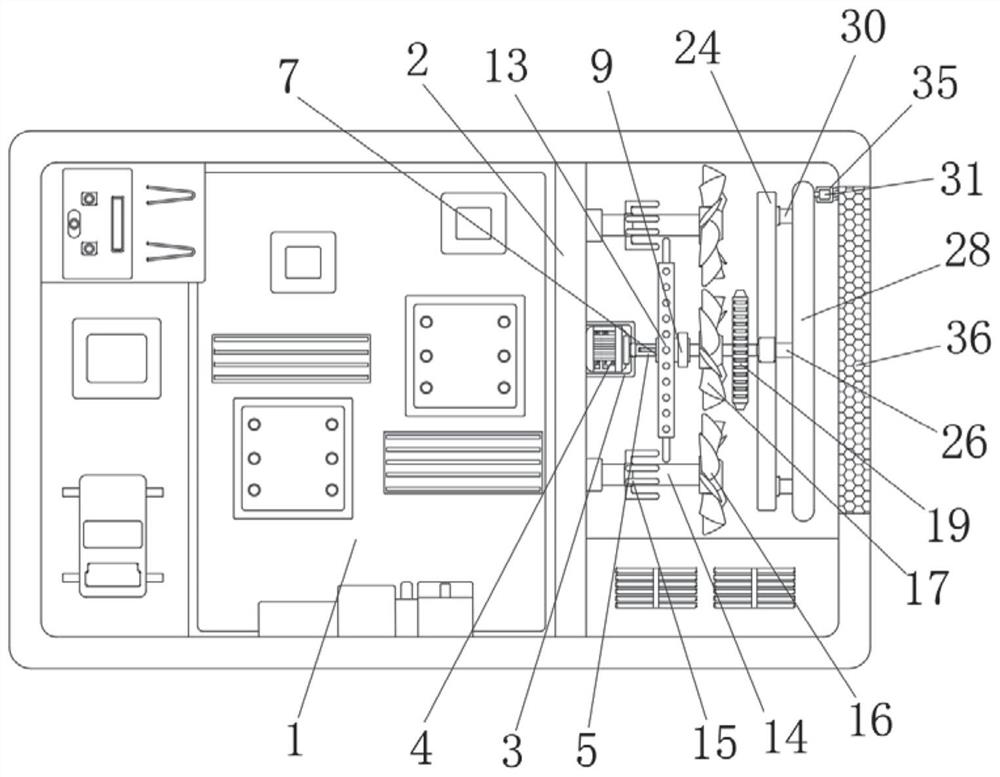

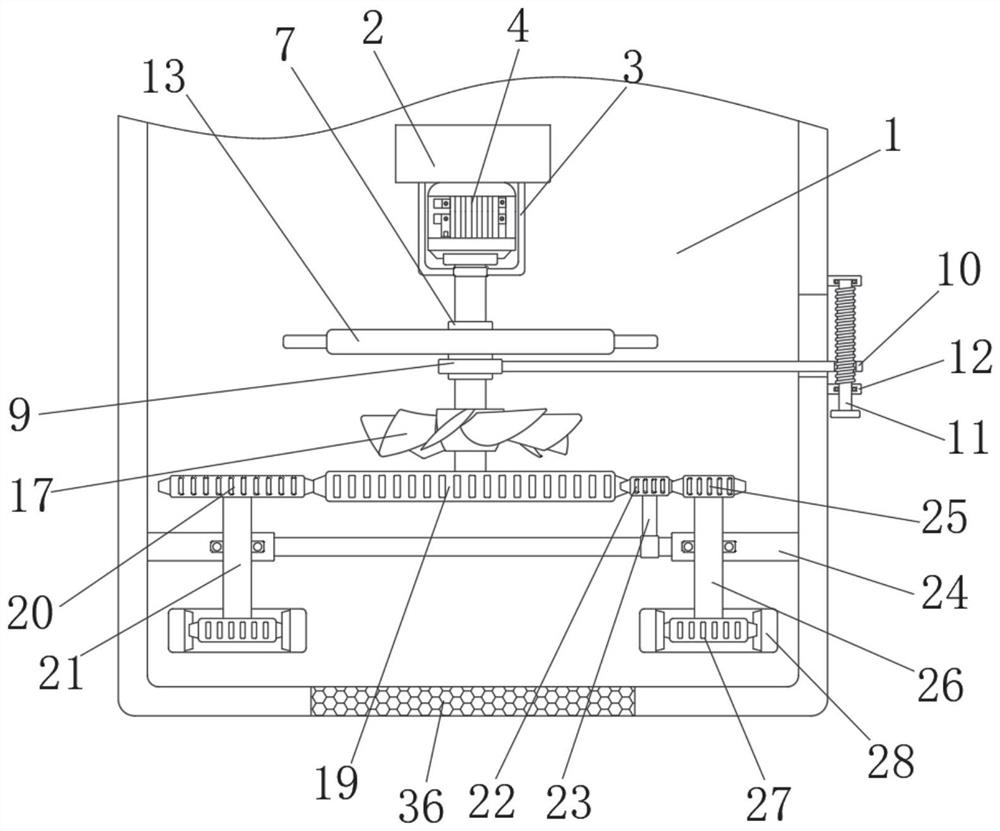

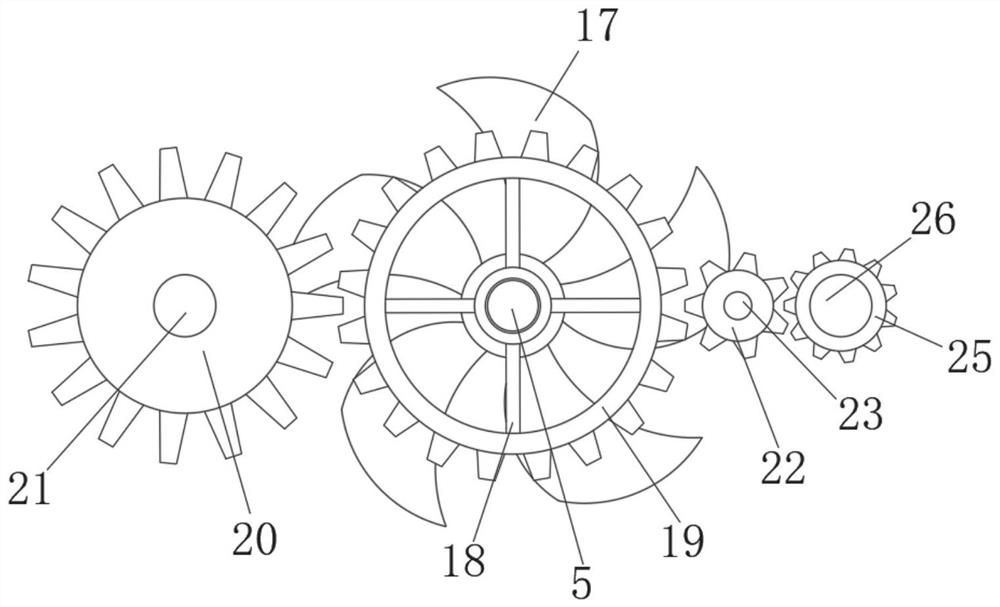

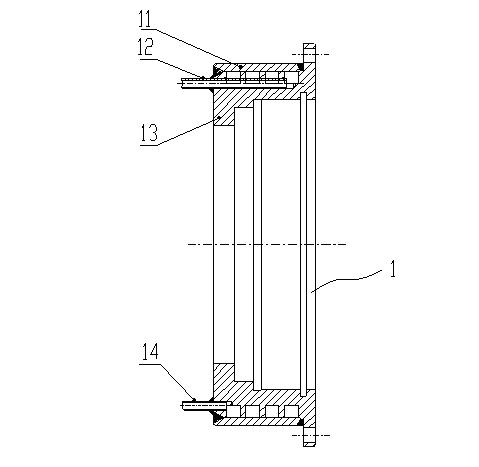

The invention discloses an intelligent power utilization safety supervision system based on the Internet of Things technology. The system comprises a cabinet body which is fixedly disposed at the outer side of a wall, the interior of the upper end of the cabinet body is fixedly provided with a transverse plate, and the two sides of the cabinet body are provided with heat dissipation holes; and the interior of the cabinet body is provided with a power distribution controller which is used for achieving the power distribution control, and meanwhile, a communication module for realizing signal transmission is mounted on the inner side of the cabinet body. The system further comprises a partition plate, the partition plate is fixedly installed on the inner sides of the heat dissipation holes, air holes are formed in the surface of the partition plate in a penetrating mode, and a driving rod is connected to the inner side of the partition plate through a shaft. The intelligent power utilization safety supervision system based on the Internet of Things technology can automatically regulate and control the heat dissipation effect according to the internal working temperature, can automatically close and extinguish fire when a fire occurs, can automatically clean the heat dissipation filter screen mechanism, realizes internal efficient heat dissipation, ensures efficient work of electrical elements, and improves the safety of power utilization. The use safety is high.

Owner:承德石油高等专科学校 +1

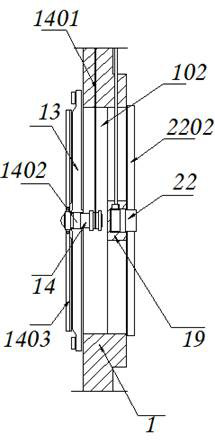

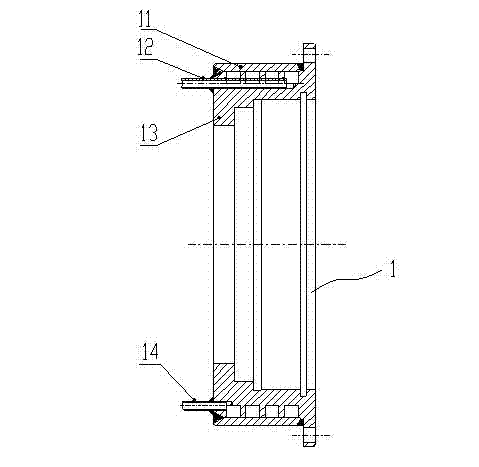

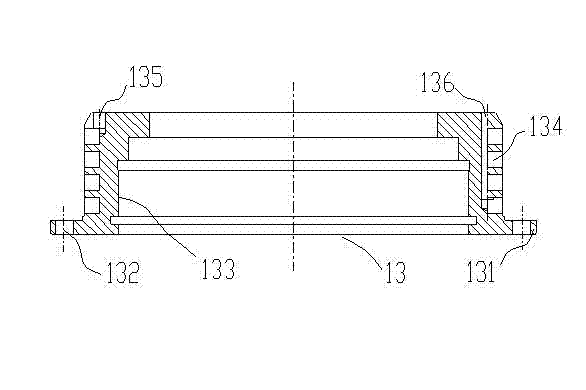

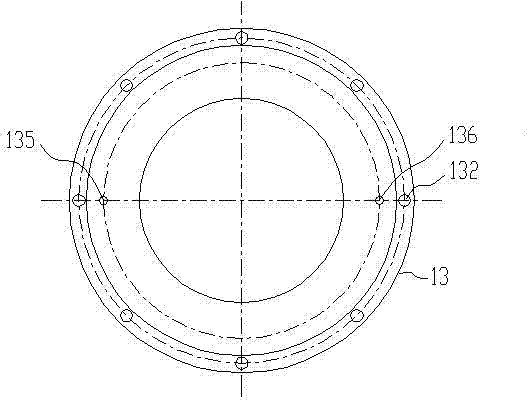

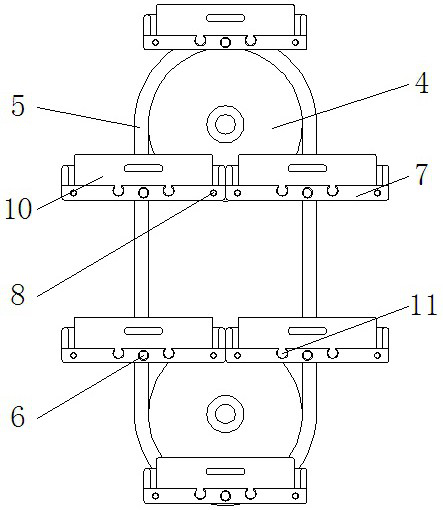

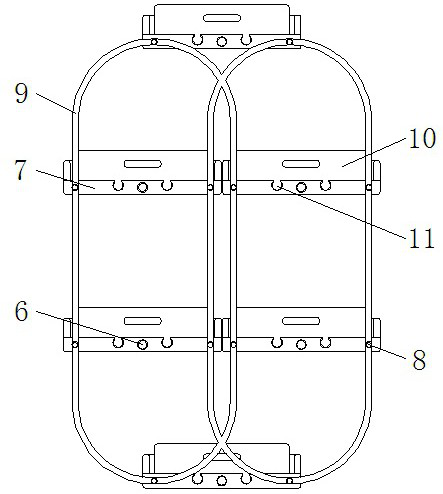

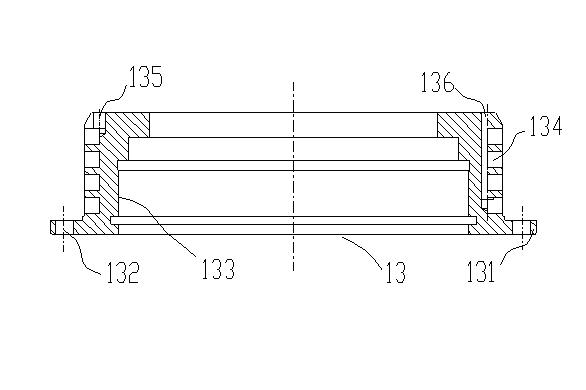

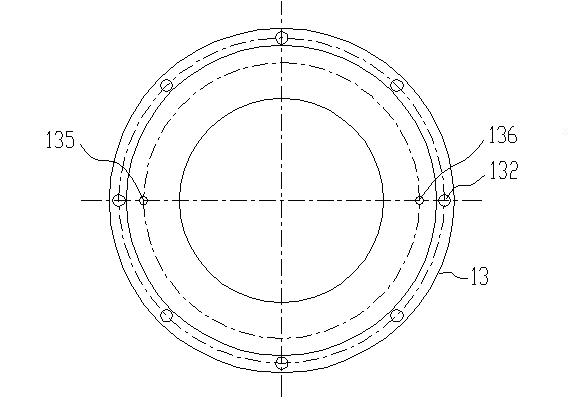

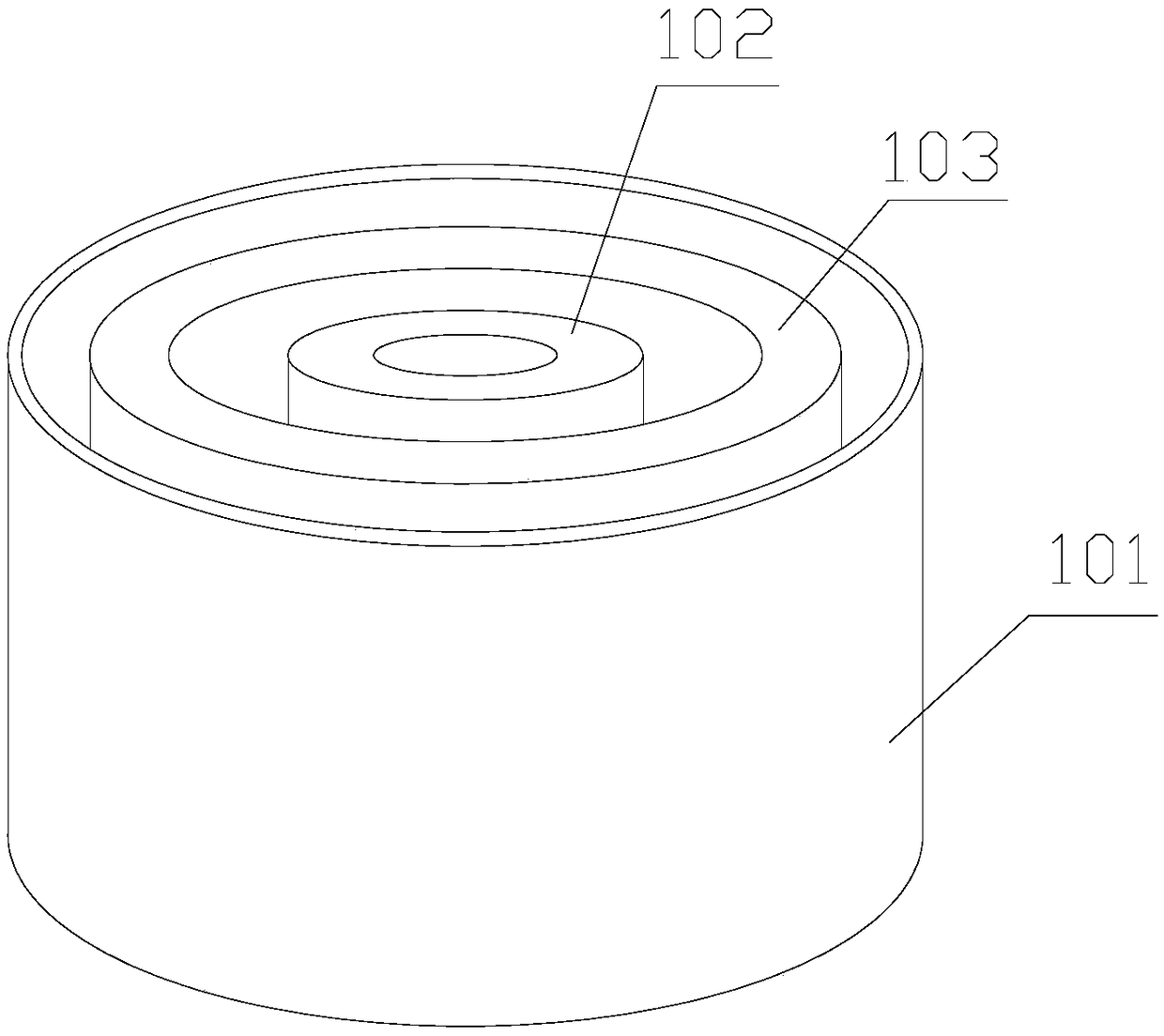

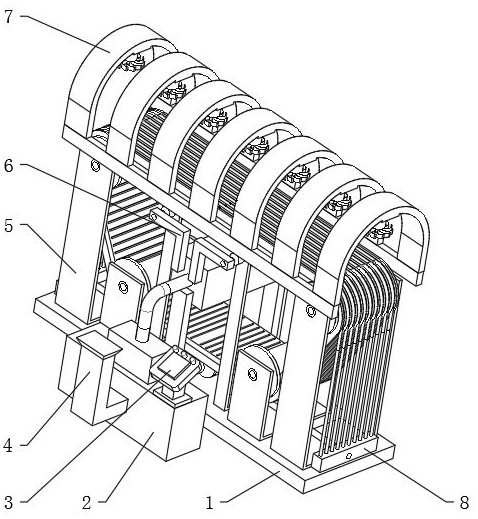

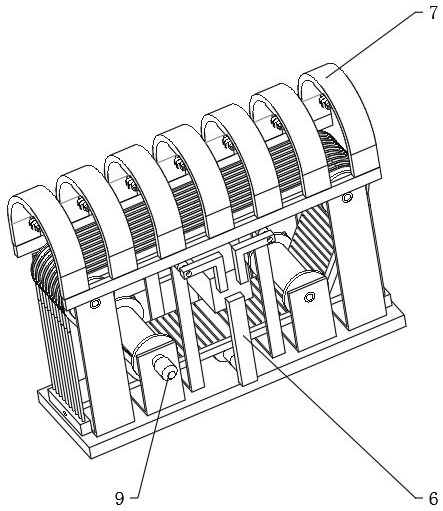

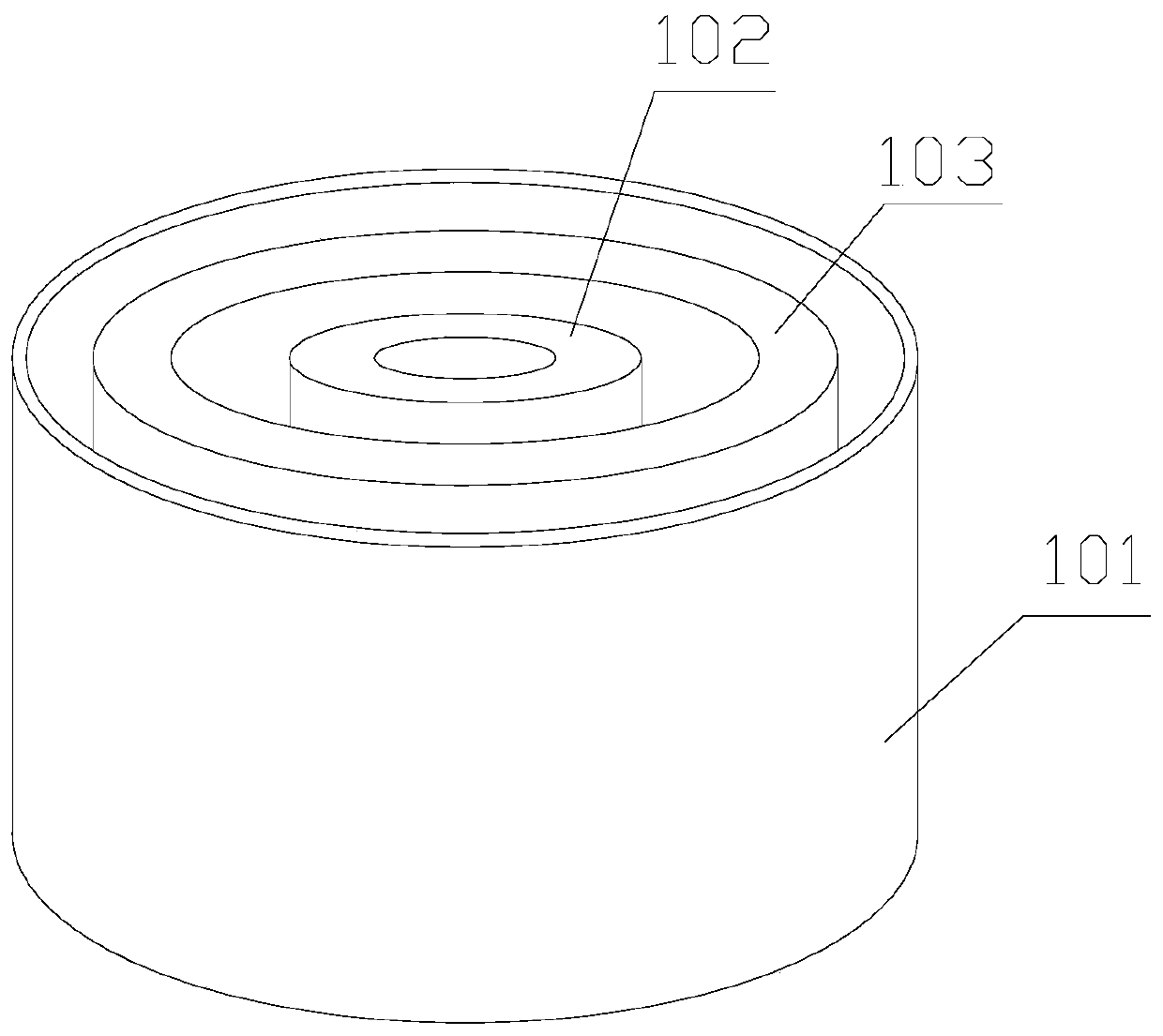

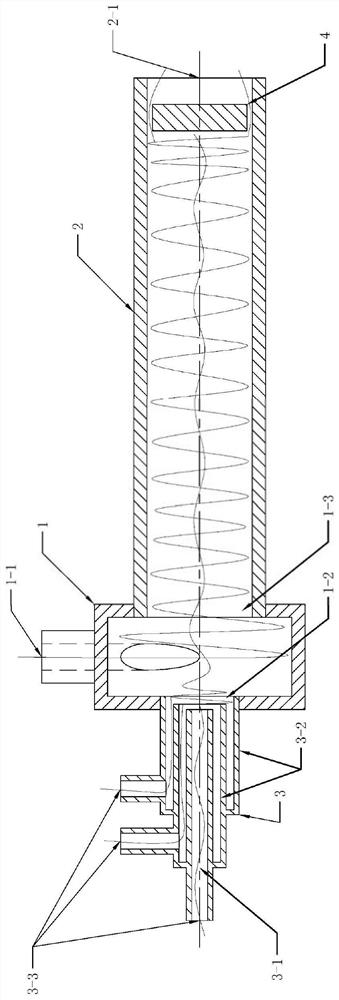

Cooling device for bearing of two-stage pusher centrifuge and manufacturing method thereof

The invention relates to the technical field of bearings of centrifuges and specifically relates to a cooling device for bearings of two-stage pusher centrifuges. The objective of the invention is to solve the problem that when temperature of materials in a two-stage pusher centrifuge is over 100 DEG C, a bearing is damaged because mere utilization of the conventional method of oil cooling can not realize drop of temperature. The invention is characterized in that: a cooling flange is provided in the core part of a deep aperture in a bearing pedestal of a two-stage pusher centrifuge; the cooling flange comprises an outer ring and an inner ring; one end of the head of the inner ring is a flange ring; the bore of the inner ring is provided with a bearing pedestal aperture; a helical groove is formed at cylindrical surface of the inner ring through the setting of helical teeth; processing short tube hole and long tube hole respectively communicate with the helical groove; a short copper tube is provided in the short tube hole while a long copper tube is provided in the long tube hole; the bore of the inner ring matches with excircle of the inner ring where the helical groove is provided, and the two are welded into an integrate part. According to the invention, the contact area between a liquid coolant and the inner ring is guaranteed, and the force received by a supporting bearing can be stabilized.

Owner:ZHEJIANG QINGJI CENTRIFUGE MFG

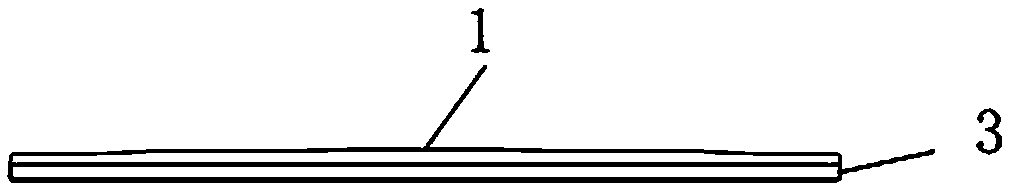

Flexible substrate real-time cooling device for reel-to-reel magnetron sputtering coating system

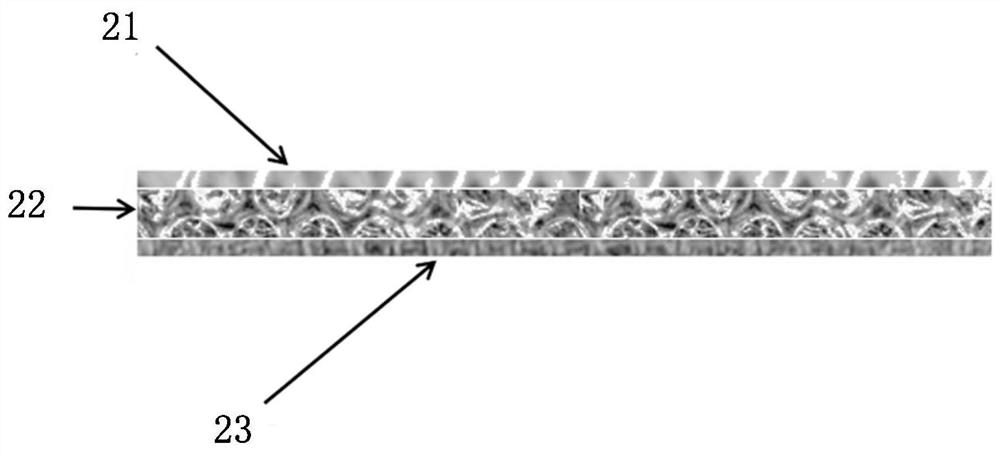

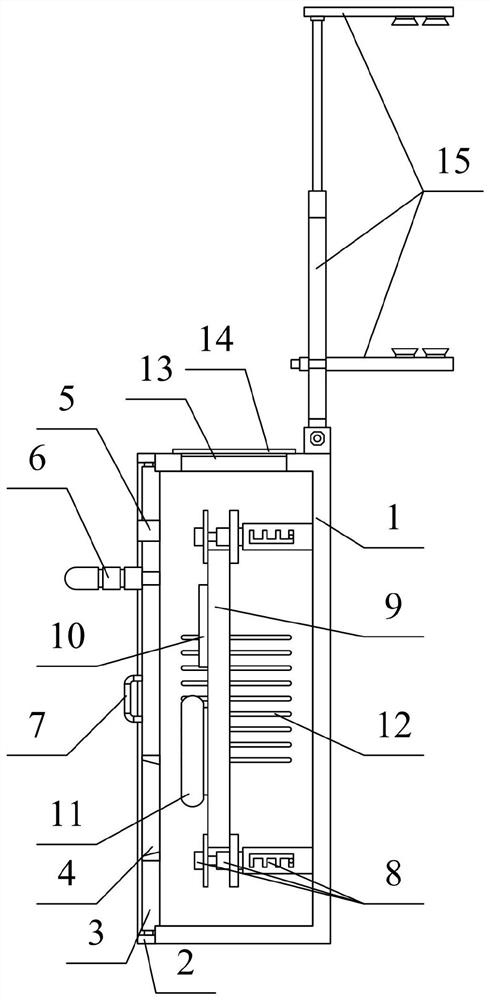

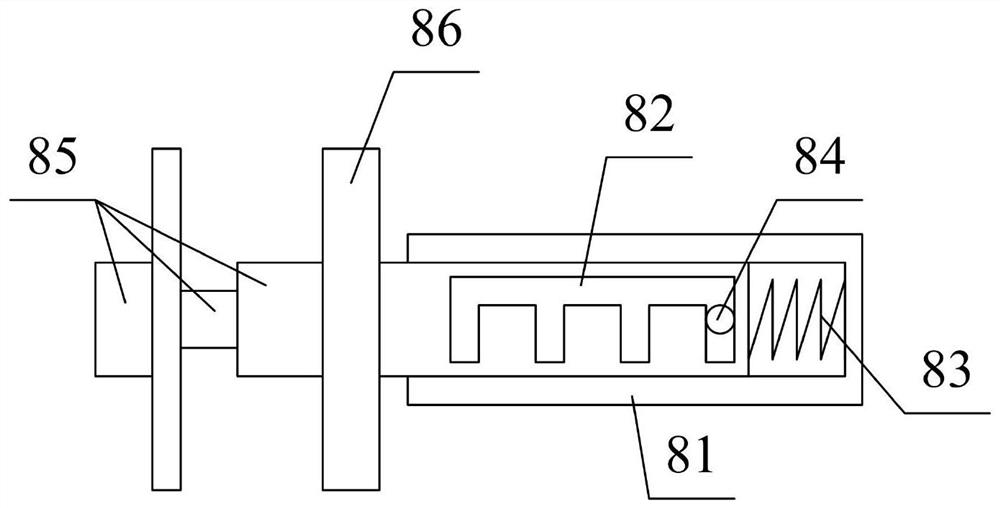

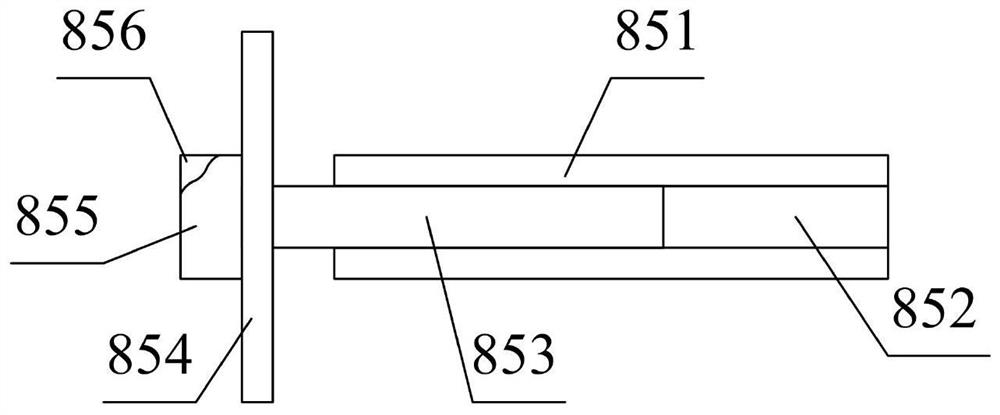

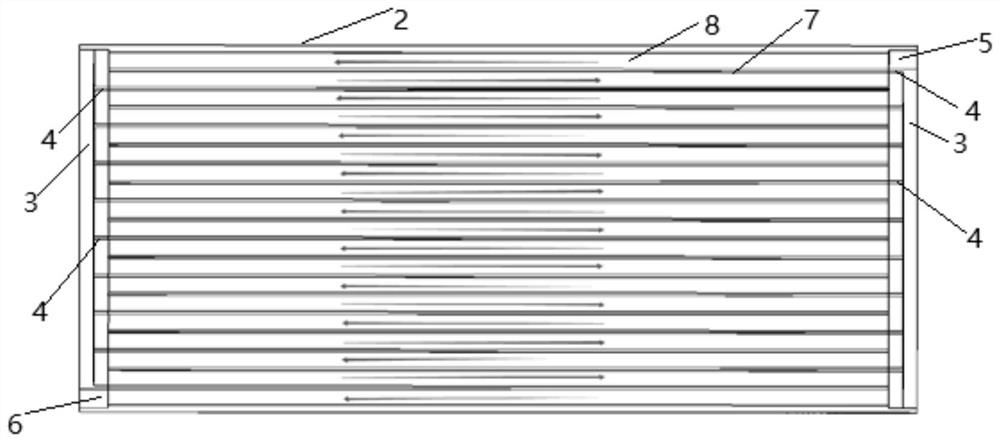

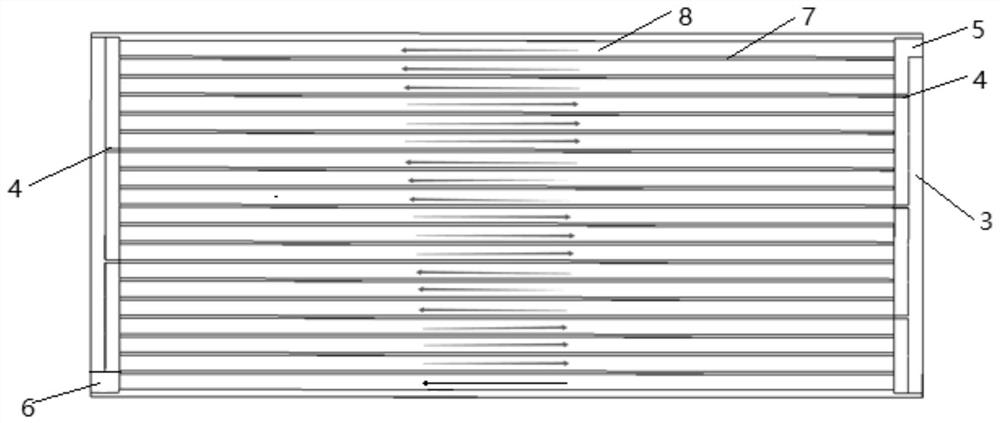

PendingCN107805791AAdjustable contactEasy to controlVacuum evaporation coatingSputtering coatingSputteringCoating system

The invention discloses a flexible substrate real-time cooling device for a reel-to-reel magnetron sputtering coating system. The flexible substrate real-time cooling device for a reel-to-reel magnetron sputtering coating system mainly comprises a cooling plate making contact with a flexible substrate. The cooling plate makes direct contact with the flexible substrate and is closely attached to the flexible substrate. A cooling water tank is formed in the back side of the cooling plate. A back plate used for sealing the cooling water tank into the back side of the cooling plate is arranged onthe back side of the cooling plate with a sealing ring. A closed cooling water flow channel formed by the cooling water tank is formed between the cooling plate and the back plate. An external connection water pipe is connected in and communicates with the cooling water flow channel. The external connection water pipe is connected with the interior of a threaded water hole formed in the back platethrough a threaded pipe in a screwing manner. A sealing ring groove is formed between the back plate and the cooling plate, wherein the sealing ring can be inlaid into the sealing ring groove to achieve sealing. A plurality of threaded through holes are formed in the back plate. Threaded countersinks are correspondingly formed in the plate face on the inner side of the cooling plate. The back plate is fixed to the back side of the cooling plate with screws from the lower part. The flexible substrate real-time cooling device for a reel-to-reel magnetron sputtering coating system has the characteristics of being reasonable in structure, convenient to use, good in cooling effect and the like.

Owner:旭科新能源股份有限公司

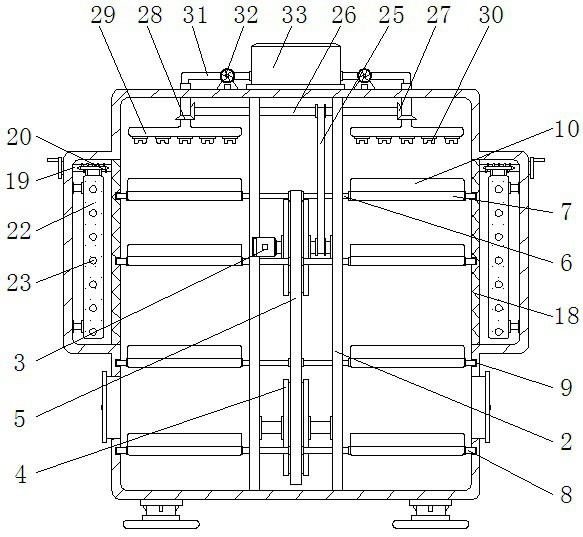

Vegetable fresh-keeping storage device capable of achieving stacking of vegetables in multiple layers for primary processing of agricultural products in production place

InactiveCN112623589ASave human effortImprove work efficiencyLarge containersTank wagonsAgricultural engineeringStructural engineering

The invention discloses a vegetable fresh-keeping storage device capable of achieving stacking of vegetables in multiple layers for primary processing of agricultural products in a production place. The vegetable fresh-keeping storage device comprises a device shell, storage frames, a cooling pipe and an atomizing nozzle, wherein a fixing plate is connected to the interior of the device shell through screws, a rotating disc is welded and fixed to an output shaft of a servo motor, a conveying belt is meshed and connected to the rotating disc, fixing shafts are rotationally connected to the conveying belt, placing frames are welded and fixed to the fixing shafts, limiting rods are welded and fixed to the placing frames, and the limiting rods are connected to the interiors of limiting grooves in a sliding mode. The vegetable fresh-keeping storage device capable of achieving stacking of the vegetables in multiple layers for primary processing of the agricultural products in the production place is provided with the placing frames, the conveying belt can drive the placing frames to move to the bottommost portion one by one, at the moment, workers only need to clamp the storage frames on the placing frames, and the stable clamping and fixing work can be carried out in combination with an ejector rod, a fixing rod and a sliding rod, so that the multi-layer stacking work can be conveniently and rapidly completed.

Owner:吴兰

Service equipment for remotely and automatically installing operating system and using method thereof

PendingCN111708422AAvoid accumulationAffect the service lifeCleaning using toolsBootstrappingElectric machineLantern

The invention discloses service equipment for remotely and automatically installing an operating system. The service equipment comprises a service equipment body and a motor, a first fixing plate is fixedly connected to the inner wall of the service equipment body, a fixing frame is fixedly connected to the center of the surface of the first fixing plate, the motor is installed in the fixing frame, and a first rotating shaft is connected to the output end of the motor. According to the invention, the lantern ring and the driving rod are arranged; the lantern ring is driven to move through thefirst connecting rod to drivethe rotating disc to move, the driving rod is driven to rotate, therefore, the first heat dissipation fan and the second heat dissipation fan arranged in the service equipment main body rotate at the same time; the heat dissipation effect can be conveniently adjusted according to the use length of the service equipment body, and the service life is prevented from beinginfluenced by long-time high temperature of parts in the service equipment body; and by arranging a cleaning rod, the surface of the cleaning rod abuts against the surfaces of the heat dissipation holes, the heat dissipation holes are cleaned when the cleaning rod moves, and dust is prevented from being accumulated on the surfaces of the heat dissipation holes.

Owner:深圳安讯数字科技有限公司

Two-stage pusher centrifuge bearing cooling device and manufacturing method

The invention relates to the technical field of bearings of centrifuges and specifically relates to a cooling device for bearings of two-stage pusher centrifuges. The objective of the invention is to solve the problem that when temperature of materials in a two-stage pusher centrifuge is over 100 DEG C, a bearing is damaged because mere utilization of the conventional method of oil cooling can not realize drop of temperature. The invention is characterized in that: a cooling flange is provided in the core part of a deep aperture in a bearing pedestal of a two-stage pusher centrifuge; the cooling flange comprises an outer ring and an inner ring; one end of the head of the inner ring is a flange ring; the bore of the inner ring is provided with a bearing pedestal aperture; a helical groove is formed at cylindrical surface of the inner ring through the setting of helical teeth; processing short tube hole and long tube hole respectively communicate with the helical groove; a short copper tube is provided in the short tube hole while a long copper tube is provided in the long tube hole; the bore of the inner ring matches with excircle of the inner ring where the helical groove is provided, and the two are welded into an integrate part. According to the invention, the contact area between a liquid coolant and the inner ring is guaranteed, and the force received by a supporting bearing can be stabilized.

Owner:ZHEJIANG QINGJI CENTRIFUGE MFG

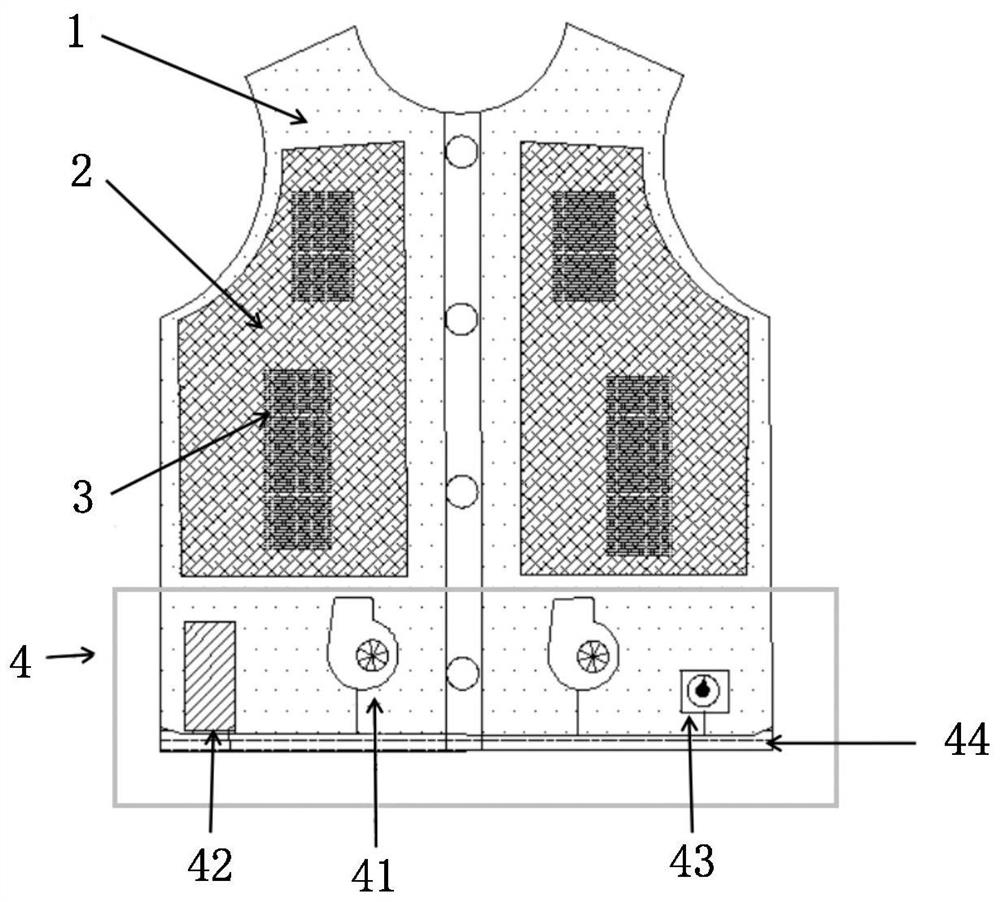

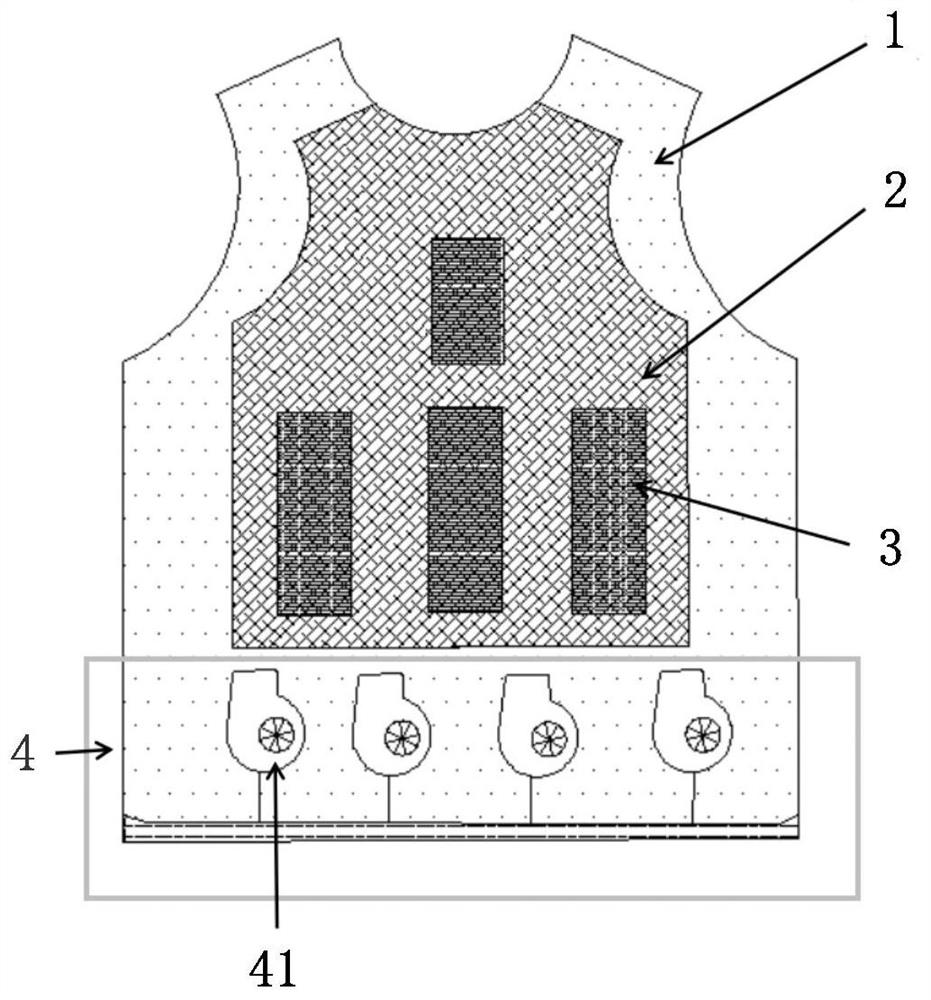

Cooling garment suitable for electric field environment

PendingCN111920117APlay a thermal insulation effectReduce releaseProtective garmentSpecial outerwear garmentsCold airMechanical engineering

The invention provides a cooling garment suitable for an electric field environment. The cooling garment comprises a garment body, a super-absorbent lining, a cold source module and a fan module. Specifically, the garment body is used for shielding an external electric field, the super-absorbent lining is arranged on the inner side of the garment body, the cold source module is arranged between the garment body and the super-absorbent lining, the fan module is arranged below the super-absorbent lining, and the fan module is used for conveying cold air provided by the cold source module. The cooling garment has the advantages that: the risk of liquid leakage is avoided, the cooling performance is good, and the cooling garment is suitable for workers who wear shielding garments and are in hot-line work scenes.

Owner:国网浙江省电力有限公司双创中心 +2

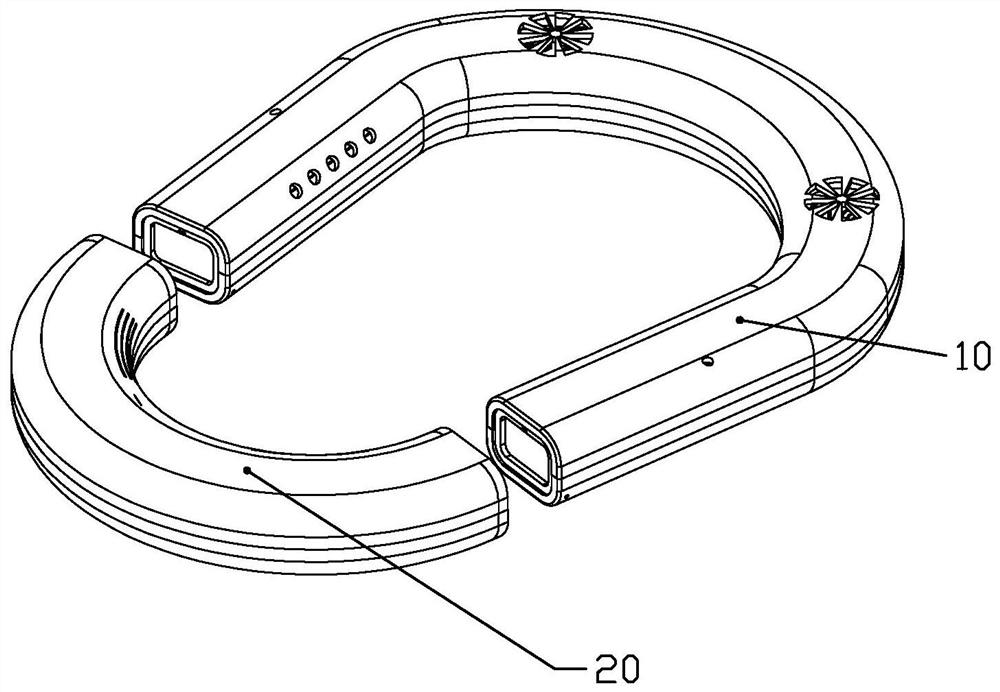

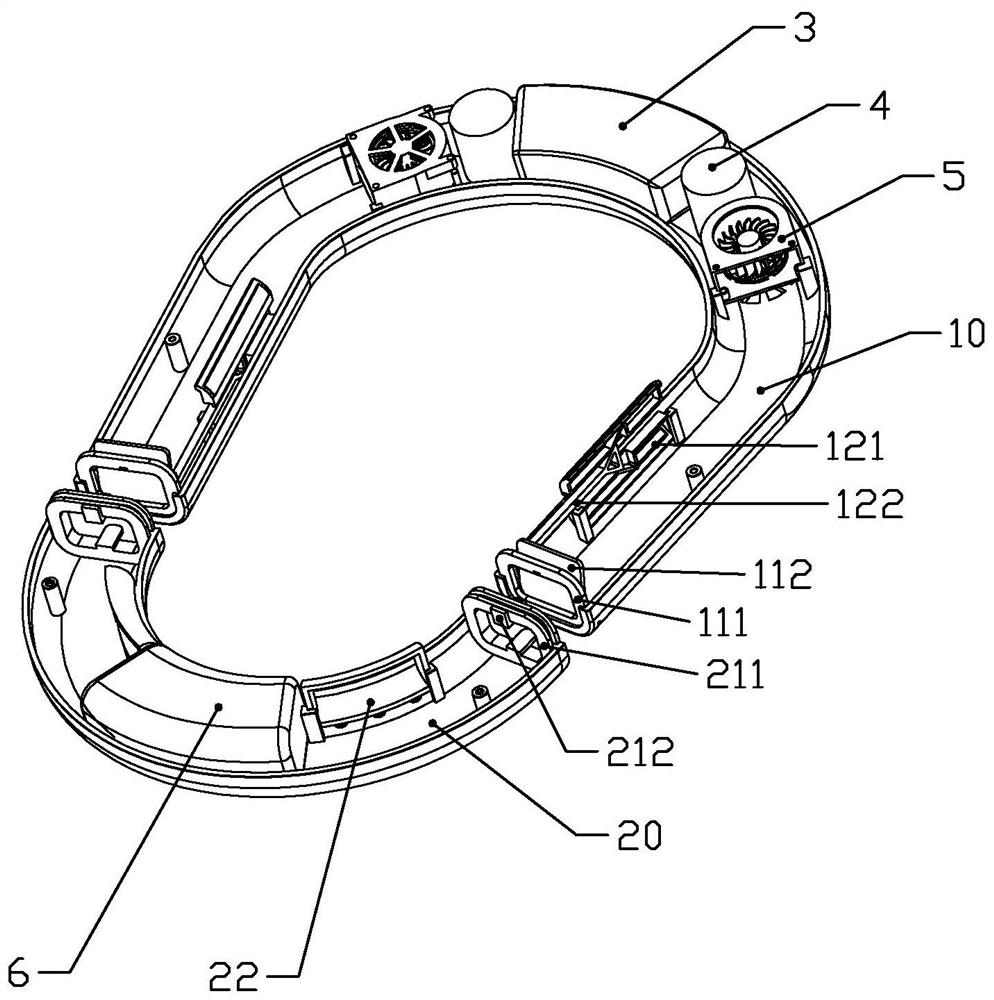

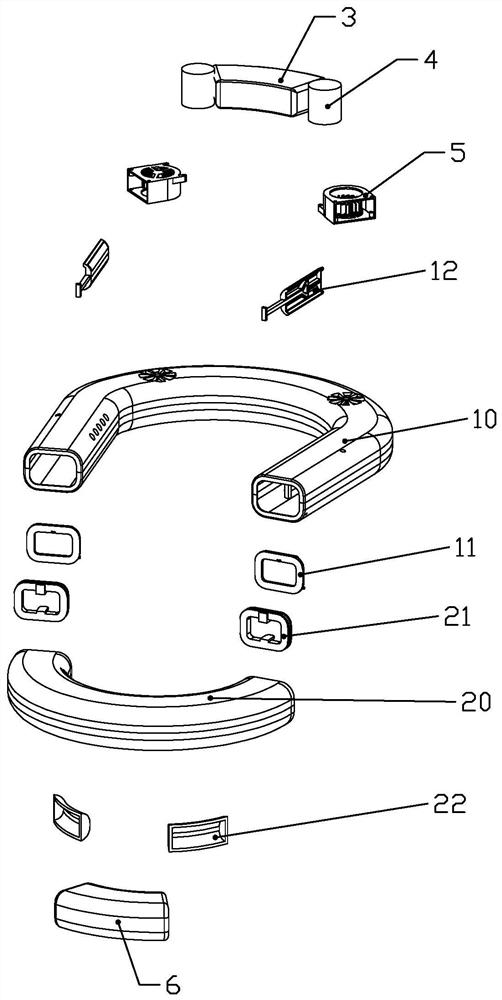

Portable intelligent fan

InactiveCN112128131AAchieve regulationControl workPump componentsLighting and heating apparatusCooling effectEngineering

The invention discloses a portable intelligent fan, and belongs to the technical field of fans. A body part and an external connection part are included. A first upper air outlet set and a first lowerair outlet set are formed in the body part. The first upper air outlet set and the first lower air outlet set do not blow air at the same time and are different in air blowing area. An upper windshield sliding part is slidably connected into the body part. A second upper air outlet set is arranged on the external connection part. A centrifugal fan is fixedly connected in the body part. Accordingto the portable intelligent fan, air can be simultaneously blown to the neck and the face or only blown to the face, and the blowing area of the neck or the face can be adjusted according to forward wearing or reverse wearing, so that the cooling effect is adjusted. The portable intelligent fan is provided with an atomizer so that the air humidity of the face or the neck can be increased, heat isabsorbed through evaporation of water, and the temperature nearby the neck or the face is reduced. Only one centrifugal fan is arranged in the portable intelligent fan so that air can be blown to theneck and the face, multiple purposes are achieved, and practicability is higher.

Owner:刘月月

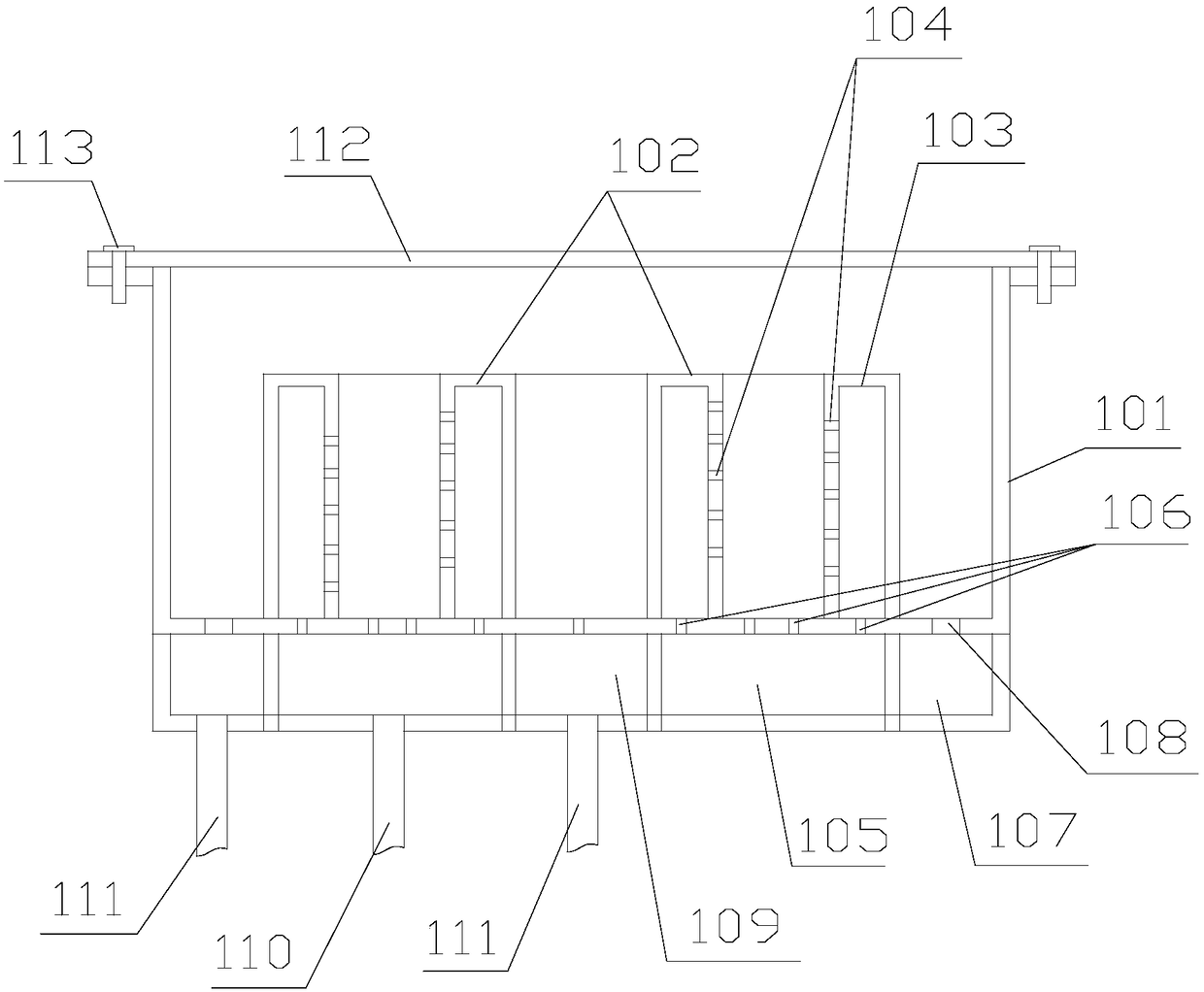

Device and process for controlling heating temperature field to purify and prepare polycrystalline silicon

ActiveCN109252216AIncreased air turbulenceGood for even distributionPolycrystalline material growthSilicon compoundsPolycrystalline siliconMetallurgy

The invention discloses a device for controlling a heating temperature field to purify and prepare polycrystalline silicon. The furnace body is provided therein with a heat insulation plate, a coolingplate, a crucible, a heating induction ring and a heat preservation tube. The heat preservation tube is provided therein with an upper graphite heating ring, a middle graphite heating ring and a lower graphite heating ring, connection rings are arranged between the upper graphite heating ring and the middle graphite heating ring, and between the middle graphite heating ring and the lower graphiteheating ring, respectively, and the connection rings are made from a high temperature resistant material with heat conduction coefficient of 10-50 W / m.k. A purification process comprises the steps: introducing a cooling gas into a cooling plate; introducing an inert gas into a furnace body, and meanwhile discharging through an exhaust pipe provided at the top of the furnace body to ensure a certain gas pressure existing in the furnace body; and controlling the upper graphite heating ring, the middle graphite heating ring, and the lower graphite heating ring to cool according to a certain procedure. The device and process for controlling heating temperature field to purify and prepare polycrystalline silicon facilitates the formation of a uniform temperature gradient, being favorable for crystal growth, and can effectively prevent the stepwise sudden change of a stepwise heat field from top down.

Owner:CHENGDU SILICON TECH CO LTD

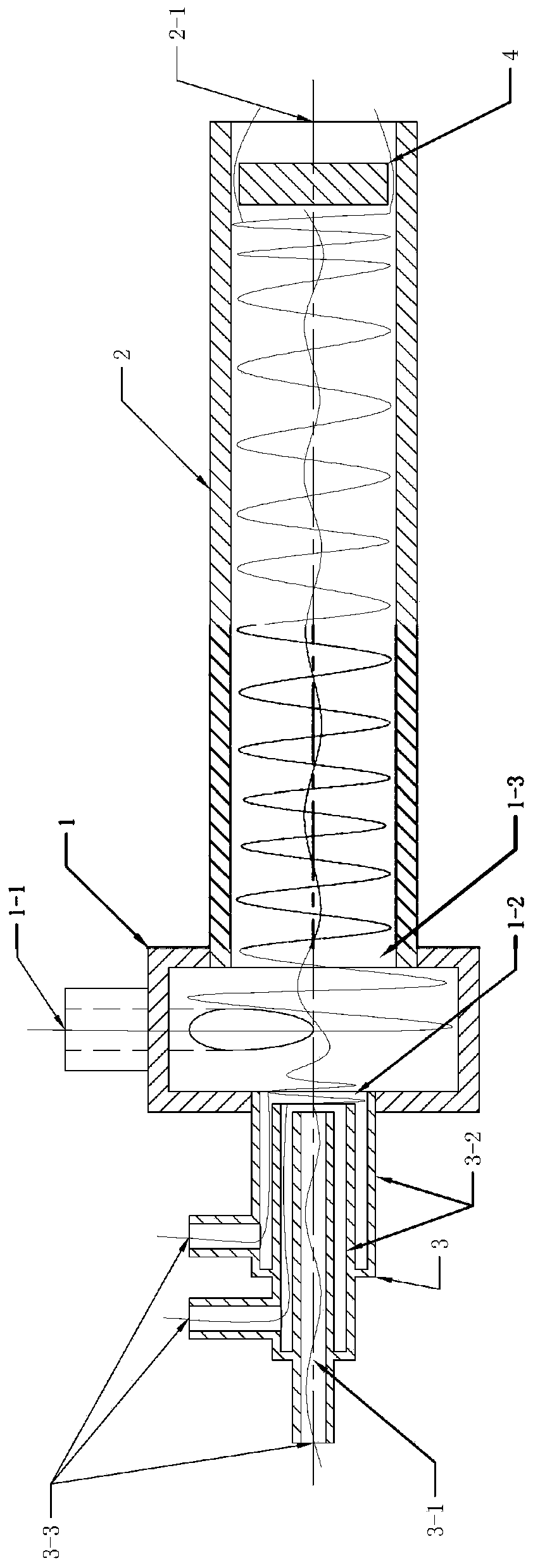

Vortex tube refrigerating device with sleeve type cold flow outlet

A vortex tube refrigerating device with a sleeve type cold flow outlet is characterized by comprising a vortex chamber, a hot end tube and a sleeve type cold end tube; two sides of the vortex chamber are respectively connected with the sleeve type cold end tube and the hot end tube; and the sleeve type cold end tube is a mutually coaxial revolving body flow channel composed of a central tube and at least one layer of outer sleeve which communicate with the vortex chamber. Compared with a traditional vortex refrigerating tube, the vortex tube refrigerating device has the advantages that air flows with different temperatures can be led out from positions with different radii of the cold end outlet of the vortex chamber, different cold air sources are switched along with change of the working condition of the vortex tube refrigerating device, and the working state of the vortex tube is adjusted by adjusting the flow of different cold air flow channels so as to adjust the refrigerating effect.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

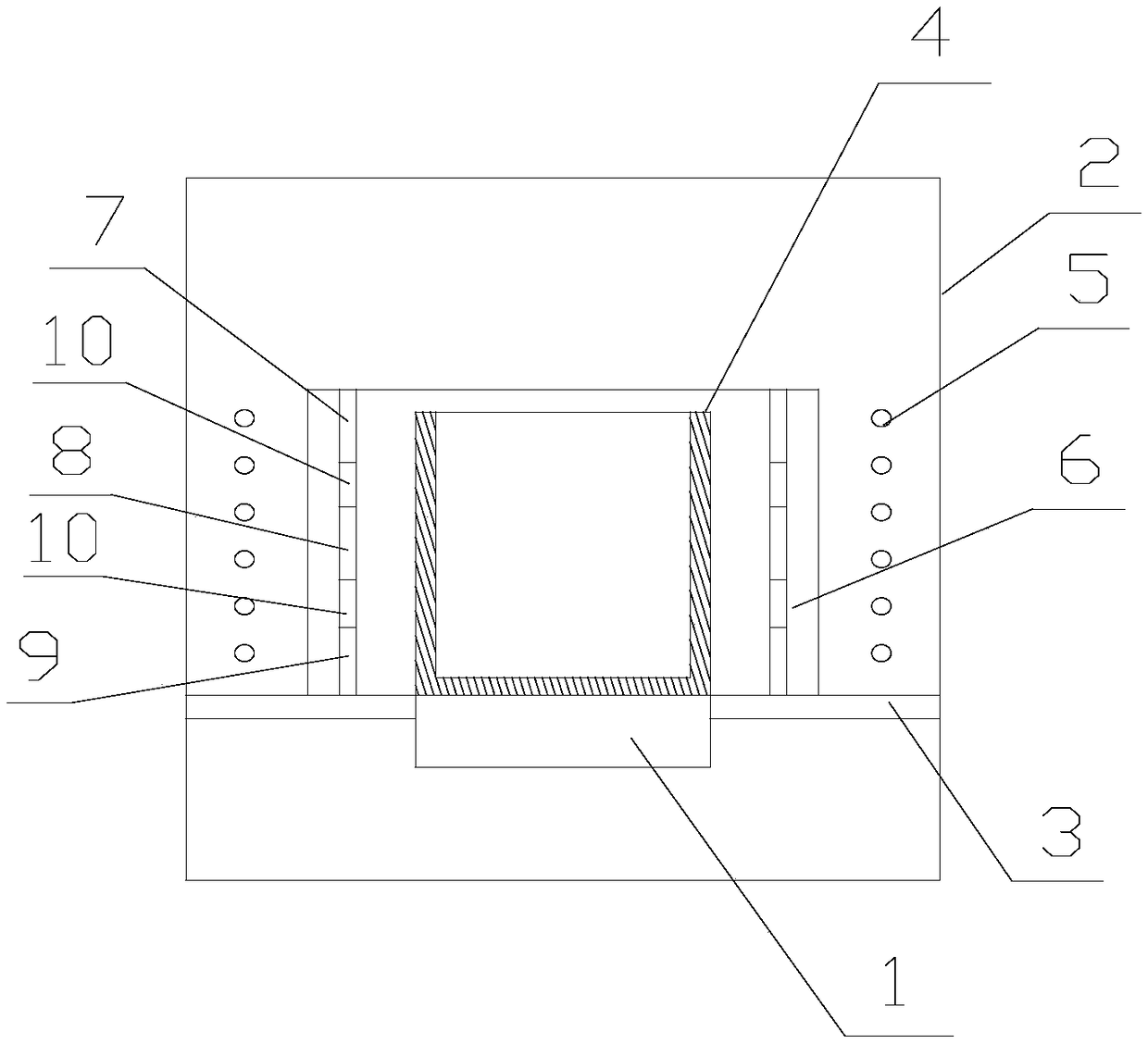

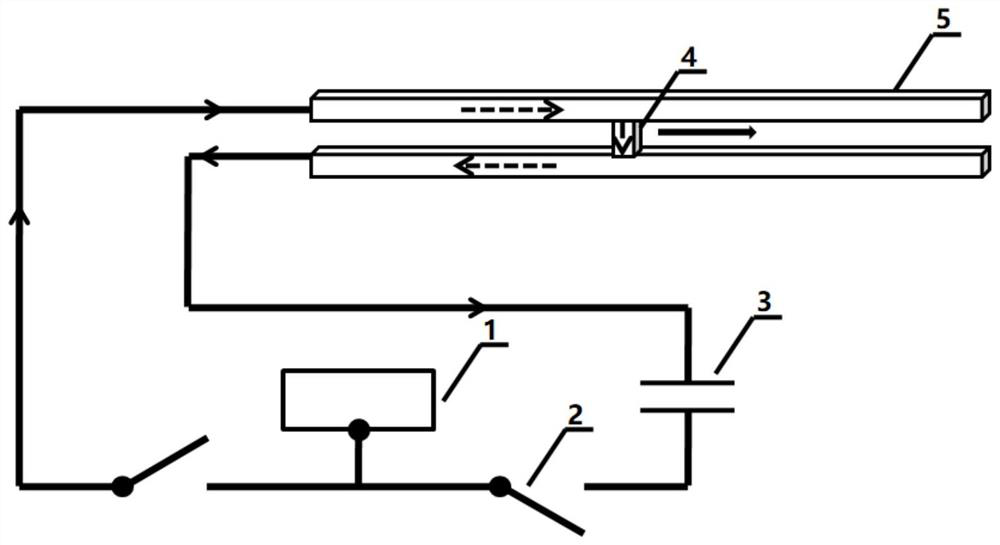

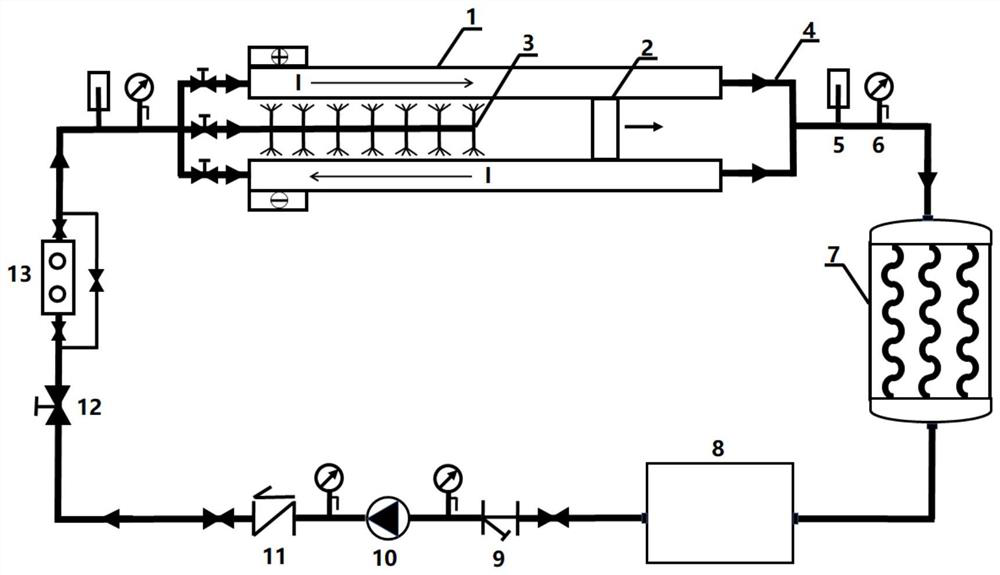

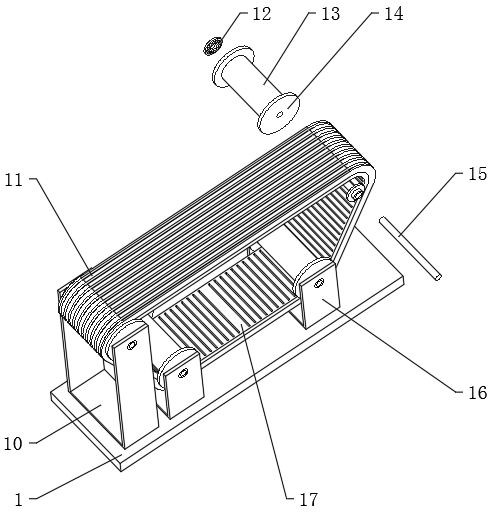

Electromagnetic track active combined cooling system

InactiveCN112066793AImprove cooling effectImprove performanceElectromagnetic launchersVentillation systemsLiquid storage tankCooling effect

The invention discloses an electromagnetic track active combined cooling system. The system comprises two electromagnetic tracks arranged in parallel, wherein an armature is arranged between the two electromagnetic tracks, a cooling pipeline is arranged over the two electromagnetic tracks, a plurality of nozzles are connected to the two sides of the cooling pipeline, the spraying directions of thenozzles are towards the inner sidewall faces of the electromagnetic tracks, through holes are formed in the two electromagnetic tracks in the axial direction, outlets of the two through holes communicate with inlets of two muzzle cooling pipelines respectively, outlets of the two muzzle cooling pipelines are connected with a muzzle temperature sensor, a muzzle pressure sensor, a heat exchanger, aliquid storage tank, a Y-shaped filter, a circulating pump, a check valve, a regulating valve, a mass flow meter, a breech pressure sensor, a breech temperature sensor and inlets of three breech cooling pipelines sequentially through a cooling header pipe, and a regulating valve is mounted on each breech cooling pipeline for regulating the flow of a cooling medium. By adopting the system, the electromagnetic track cooling effect can be improved, and an optimal internal and external cooling scheme can be determined through regulation.

Owner:TIANJIN UNIV

Cooling equipment for processing of electric motorcycle accessories

InactiveCN112595021AReduce contact areaIncrease relative pressureLighting and heating apparatusCooling fluid circulationElectric machineryWater circulation

The invention discloses cooling equipment for processing of electric motorcycle accessories, and relates to the field of electric motorcycle production. The problem that existing equipment cannot conduct cooling in the conveying process is solved. The equipment specifically comprises a bottom plate, a conveying assembly and a middle assembly are fixedly connected to the outer wall of the top of the bottom plate, an upper penetrating assembly is fixedly connected to the outer wall of the top of the conveying assembly, and an attaching assembly is fixedly connected to the outer wall of the top of the bottom plate. According to the cooling equipment, the conveying assembly is arranged, a power motor is started to drive a second belt and a first belt to move, meanwhile, accessory conveying work is executed, then a bundling box is filled with cooling water, when the cooling water passes through a connecting pipe and enters a configuration barrel, due to the water flow effect, an impeller can be driven to rotate, then water in a flow guide pipe is stirred, and water circulation flowing in the attaching assembly is achieved; and due to the fact that an attaching seam pipe is attached to atransverse groove of the first belt, contact between the cooling water and accessories is more sufficient, and cooling is accelerated.

Owner:何鹏程

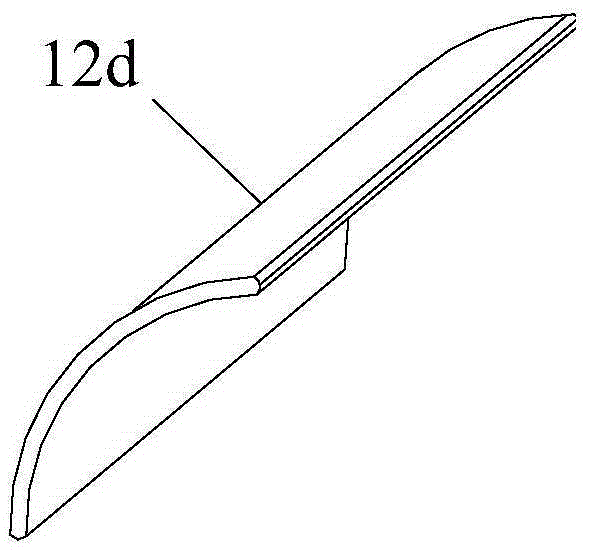

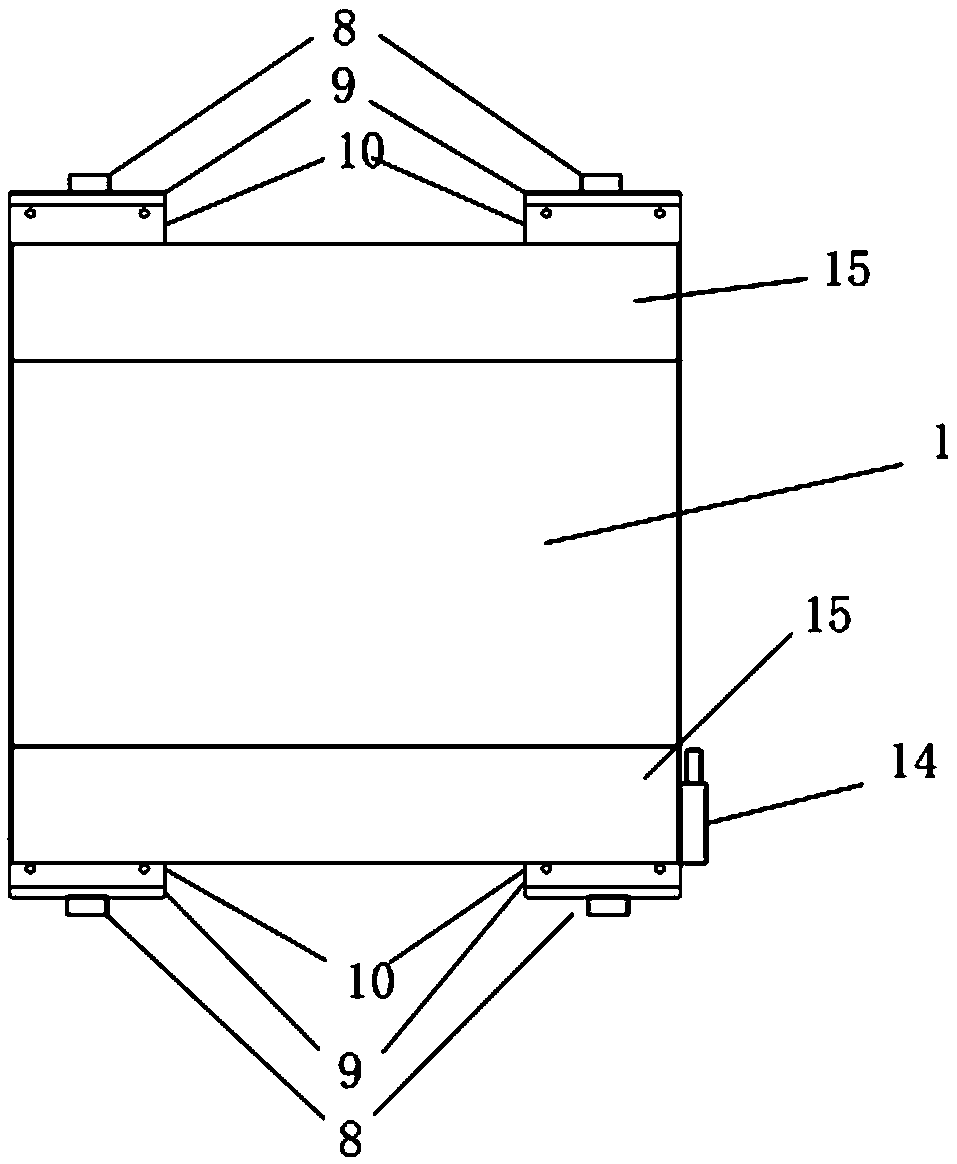

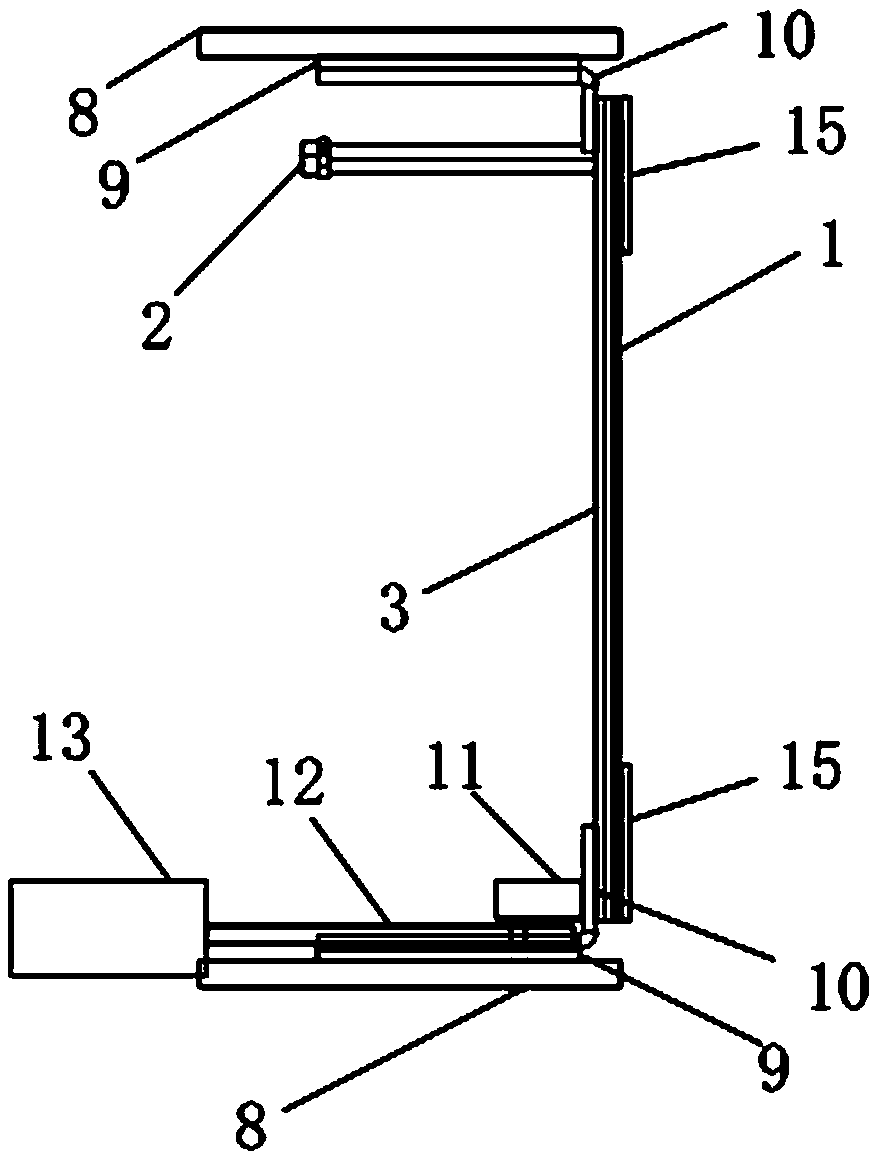

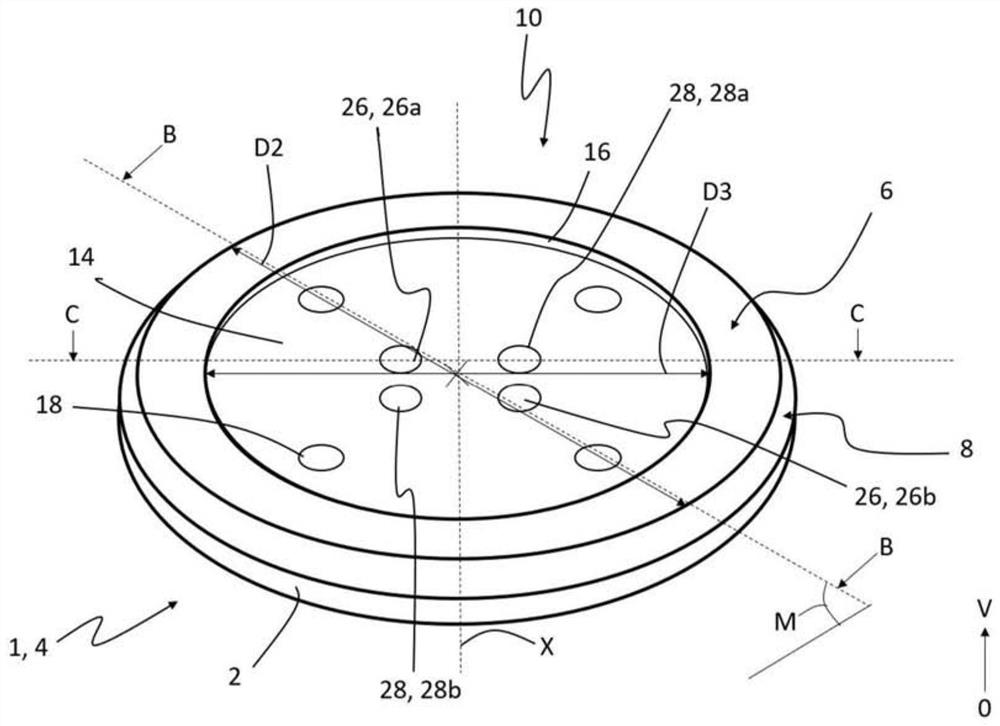

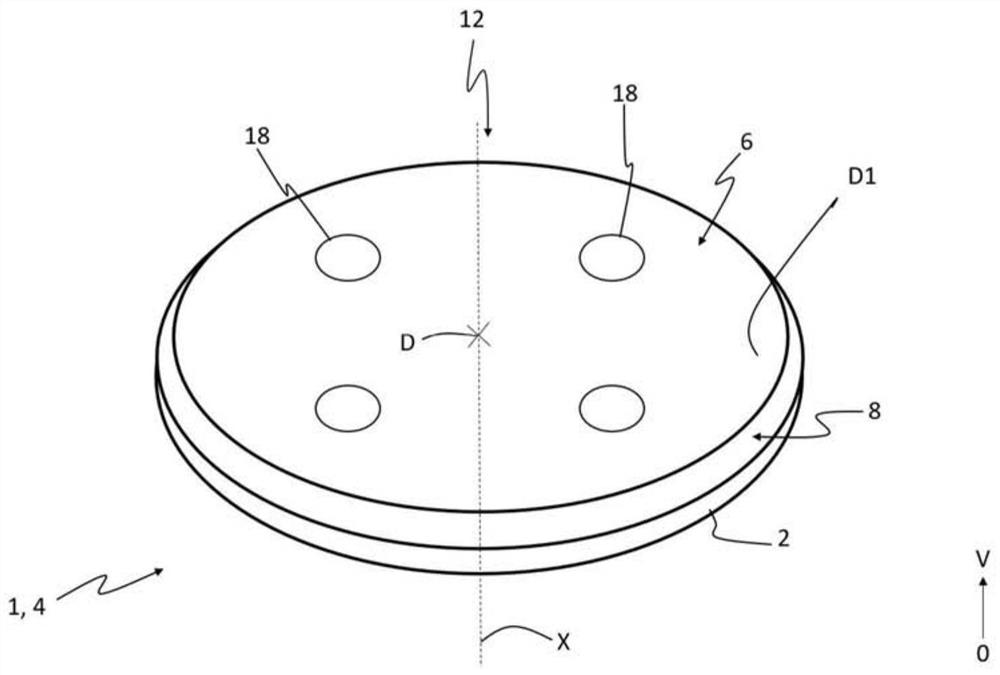

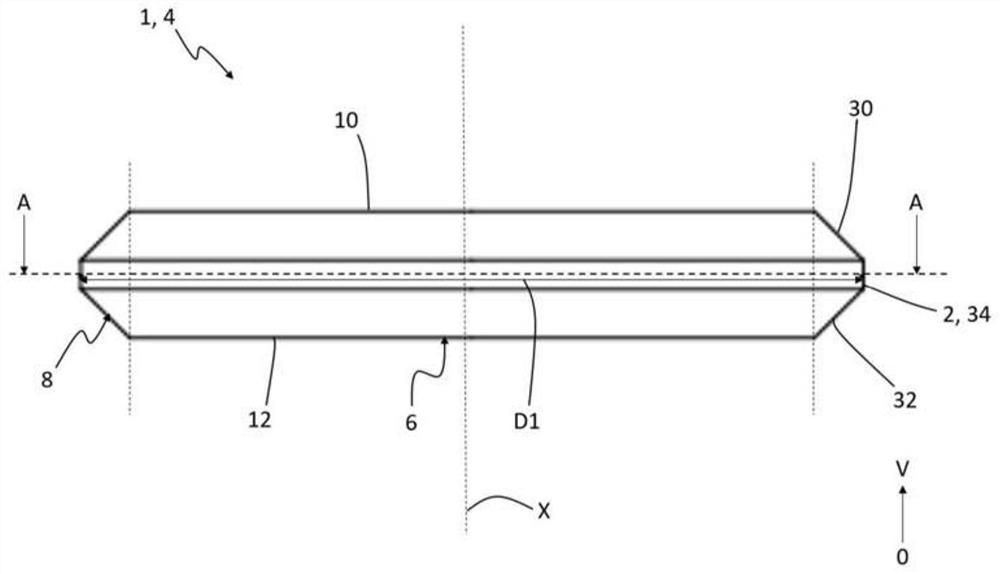

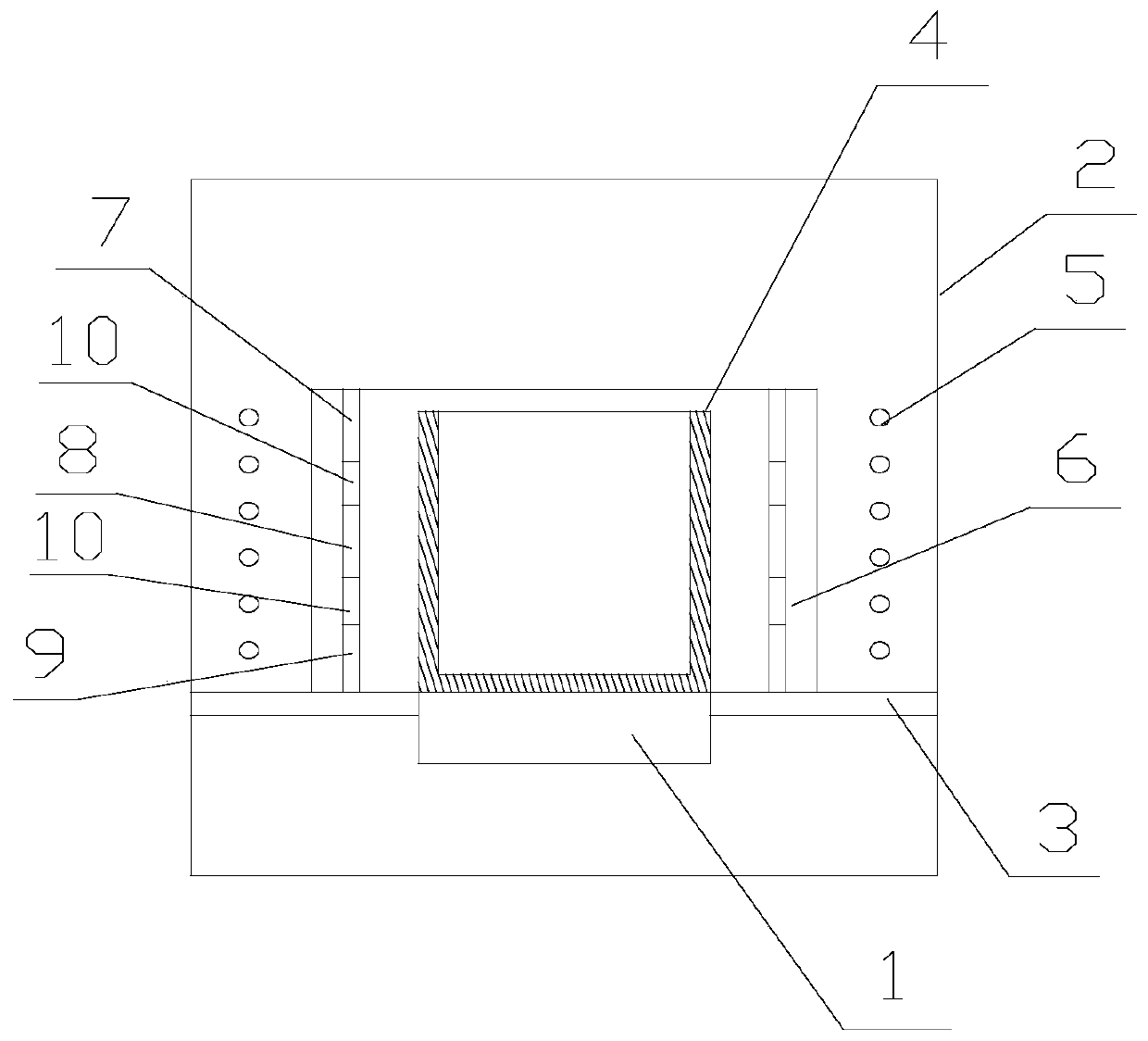

Welding wheel

PendingCN113020827AAdjust cooling effectWelding/cutting auxillary devicesRectilinear seam weldingEngineeringMechanical engineering

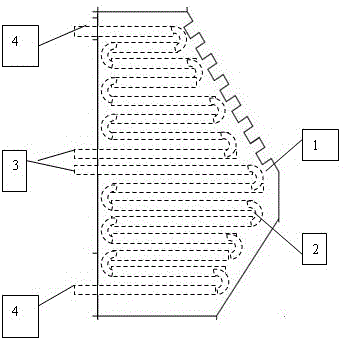

The subject of the invention is a welding wheel (1) for welding metal sheets (52, 54), the wheel (1) comprising a contact surface (2) inscribed within a disk (4) having a diameter (D1) of less than 100 mm, and a cooling system (20) comprising a first cooling circuit (22) and a second cooling circuit (24).

Owner:GAZTRANSPORT & TECHNIGAZ

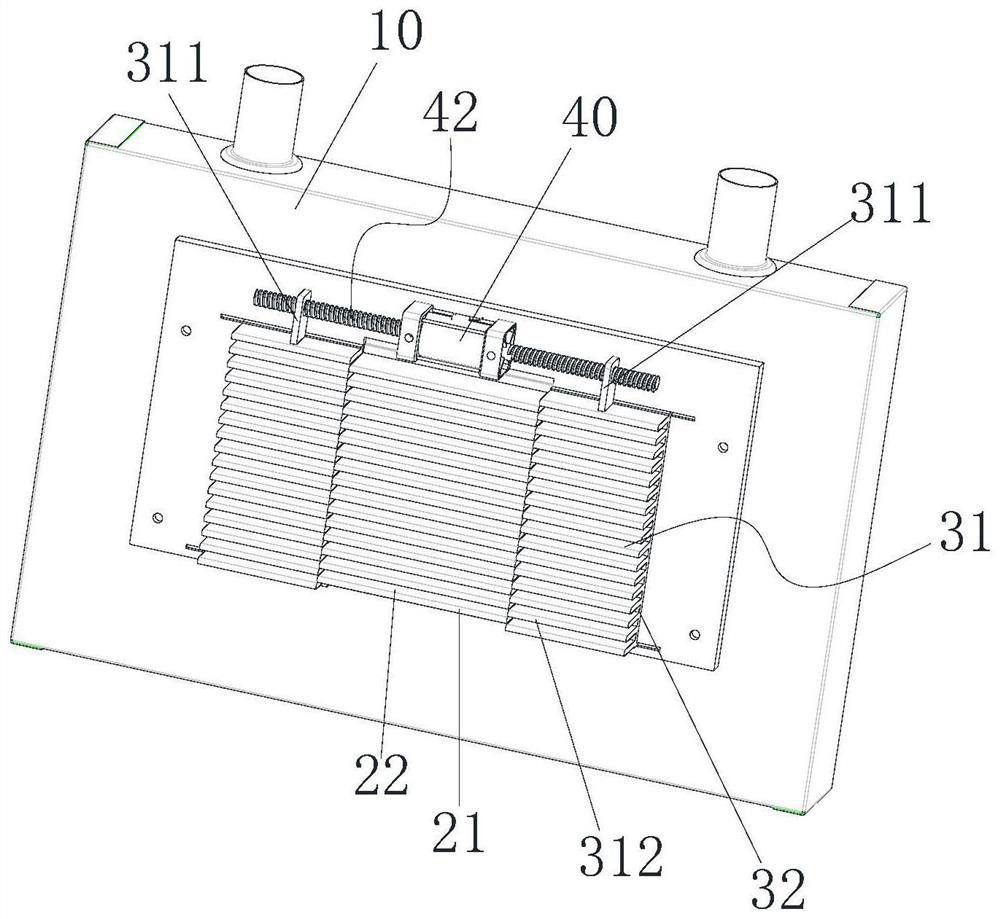

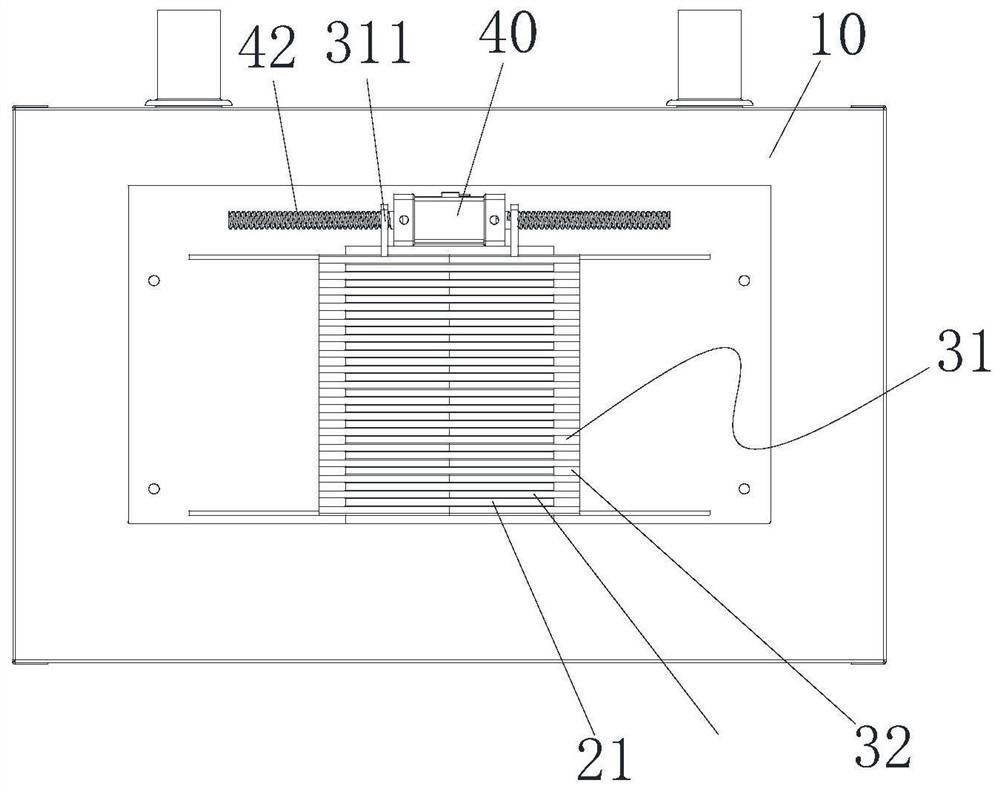

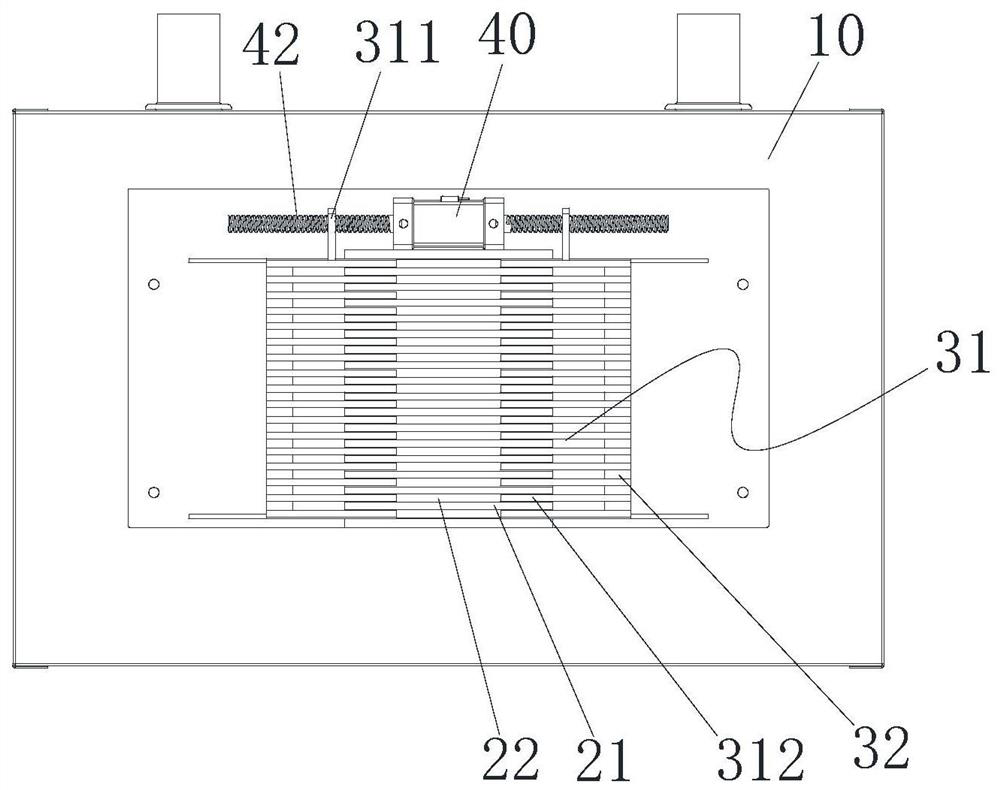

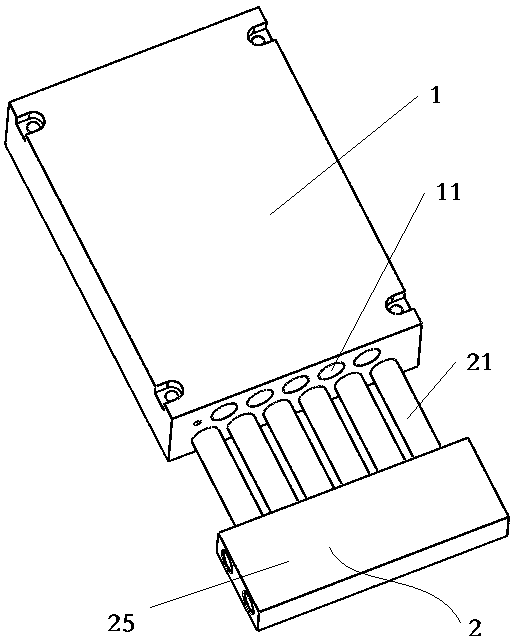

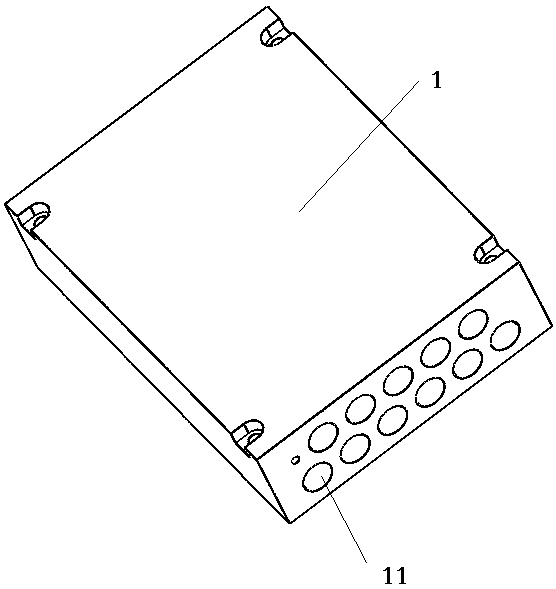

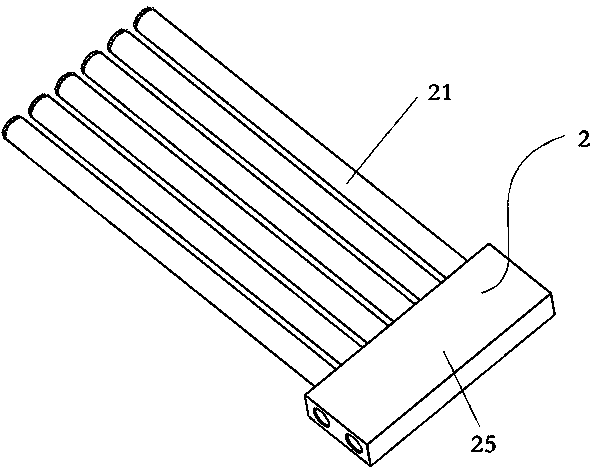

Electric appliance box and air conditioner

PendingCN112351617AChange the heat transfer areaAdjust cooling effectMechanical apparatusCasings/cabinets/drawers detailsPhysicsElectrical equipment

Owner:GREE ELECTRIC APPLIANCES INC

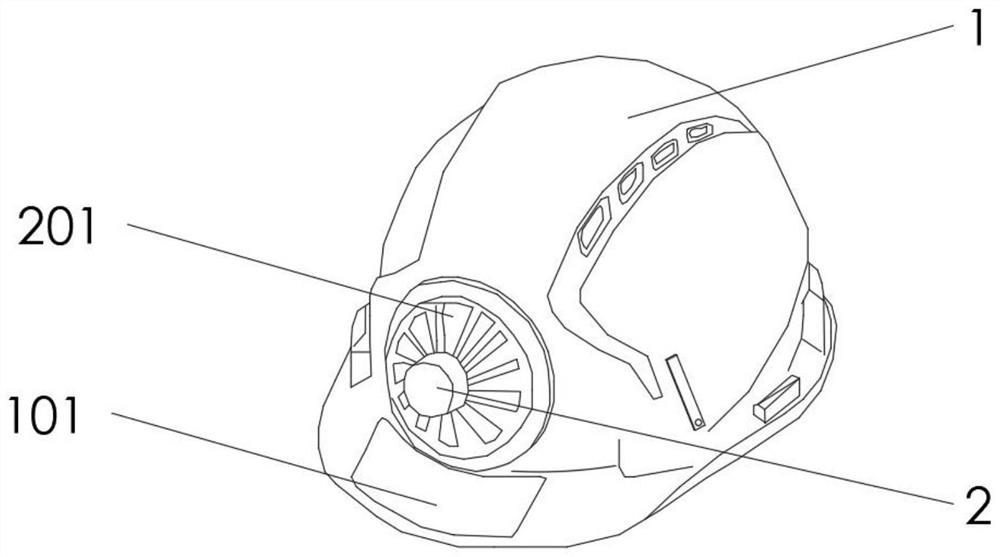

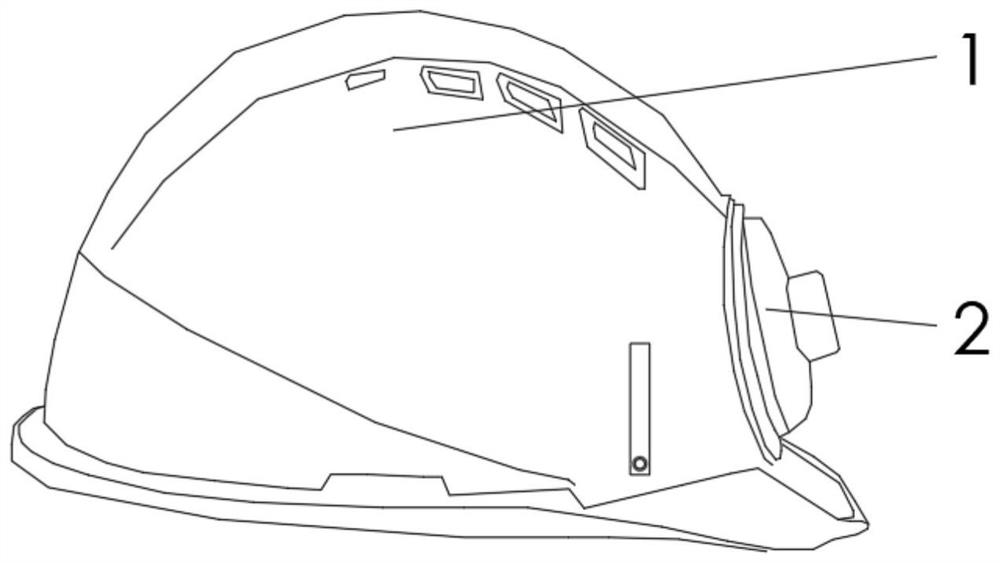

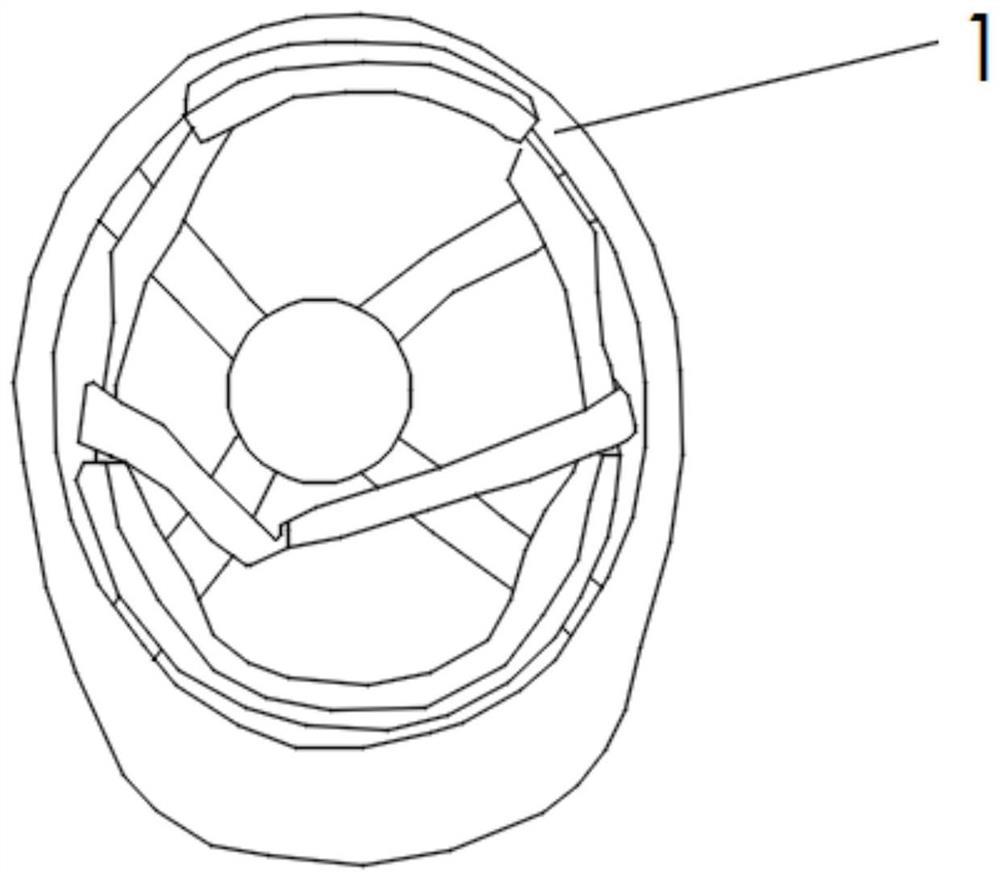

Heat dissipation safety helmet

PendingCN112869285AWearer comfortImprove heat dissipationHelmetsHelmet coversEngineeringScalp itching

The invention discloses a heat dissipation safety helmet. The heat dissipation safety helmet comprises a helmet shell; a heat dissipation part which is fixedly connected to the front side of the helmet shell, and the heat dissipation part is communicated with the inner surface and the outer surface of the helmet shell; and air guide mechanisms which are fixedly installed on the left side and the right side of the interior of the helmet shell correspondingly, and the front ends of the left air guide mechanism and the right air guide mechanism communicate with the left side and the right side of the heat dissipation part. The problems that the inside of an existing safety helmet is not ventilated, scalp itching is caused, and a wearer feels uncomfortable are solved.

Owner:GUIZHOU ELECTRIC POWER DESIGN INST

Device and process for purification and preparation of polysilicon by controlling heating temperature field

ActiveCN109252216BPromote growthFast heating and cooling effectPolycrystalline material growthSilicon compoundsCrucibleGraphite

Owner:CHENGDU SILICON TECH CO LTD

Novel computer fault alarm device

InactiveCN114017606AAdjust cooling effectRealize clamping and fixingStands/trestlesDigital processing power distributionVoltmeterSingle chip

The invention provides a novel computer fault alarm device, which comprises a mounting box, a mounting frame, a sealing door, a display screen, a buzzer, an alarm lamp, a handle, a movable dismounting column structure, a circuit board, a single chip microcomputer, an electronic voltmeter, heat dissipation holes, a heat dissipation fan, a protective net and a movable dismounting frame structure, and is characterized in that the mounting frame is welded to the outer side of the left end of the mounting box; a hinge of the sealing door is mounted at the rear part of the inner wall of the mounting frame; the display screen is embedded in the lower side of the interior of the sealing door; the buzzer and the alarm lamp are embedded in the upper side of the interior of the sealing door. The handle is installed in the middle of the front portion of the left surface of the sealing door through bolts. The device has the beneficial effects that through the arrangement of the movable dismounting column structure, the installation position is clamped and fixed for use.

Owner:LAIWU VOCATIONAL & TECHNICAL COLLEGE

A primary mold vertical cooling mold

The invention belongs to the technical field of glass bottle moulds, and specifically discloses a vertical cooling mold for a blank mold, which includes two semi-primary molds with the same size, structure and shape that can be fastened to each other. A cavity is opened in the semi-primary mold, and the cavity includes a bottle Bottom cavity, bottle body cavity and bottleneck cavity, the inner wall of the bottleneck cavity is evenly opened with a number of exhaust grooves along the circumferential direction, and the hole depth of the exhaust grooves is 0.10-0.12mm. The object of the present invention is to provide a blank cooling mold to solve the problem of low cooling efficiency of the neck.

Owner:重庆华彬伟玻璃有限公司

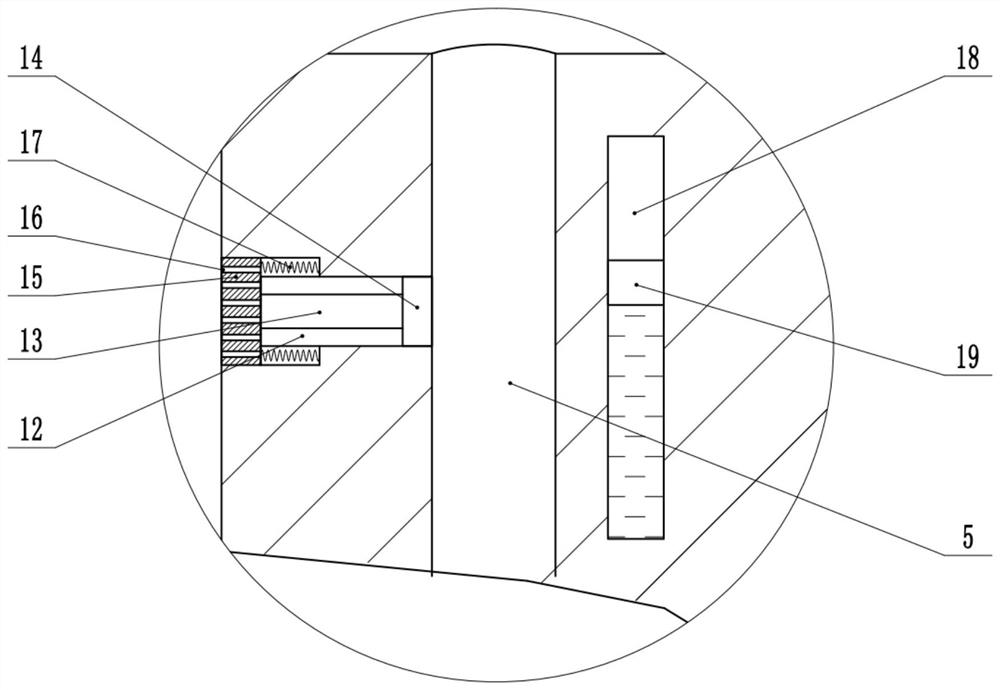

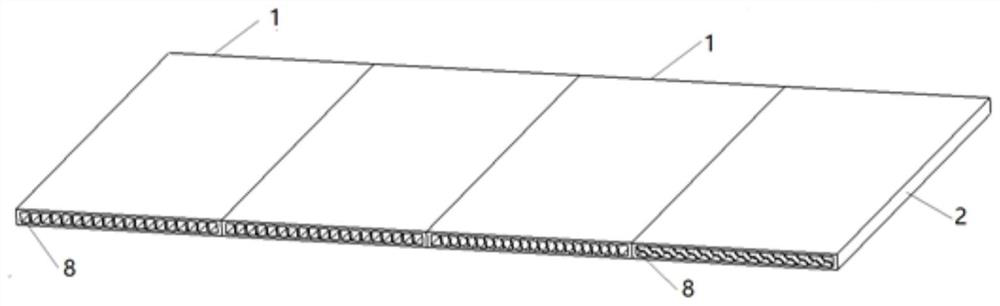

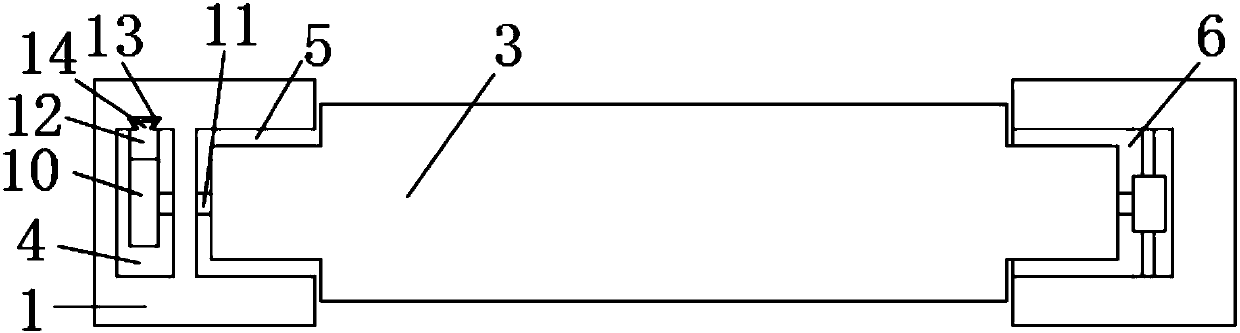

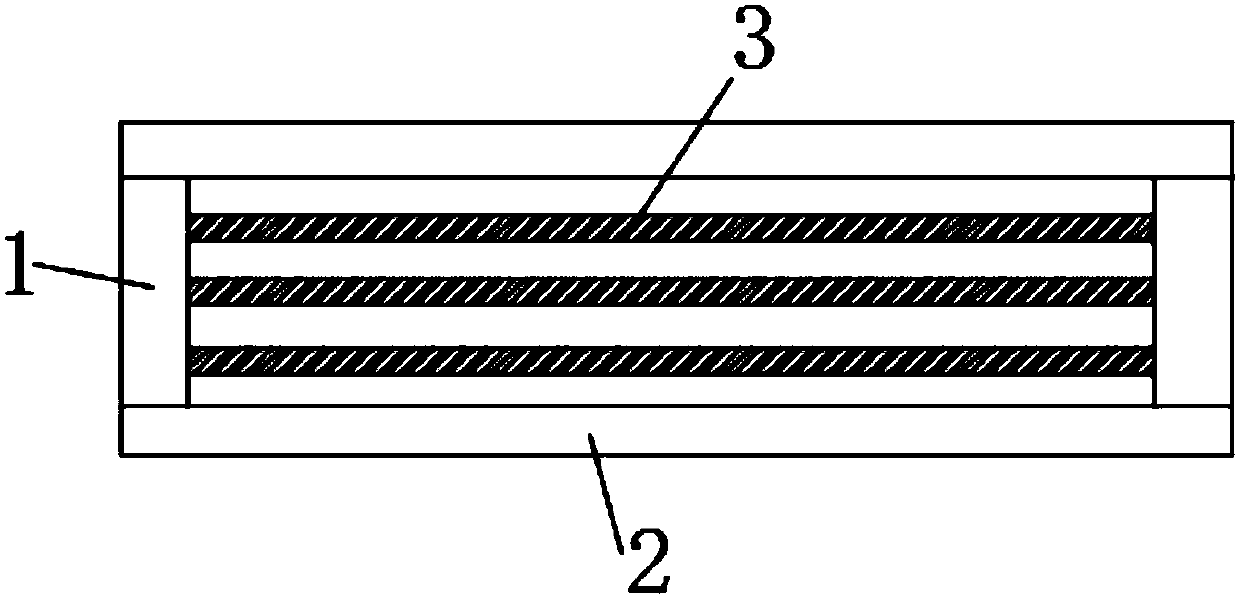

Water cooling plate

PendingCN113320370AAdjust cooling effectImprove flexibilityElectric propulsion mountingSecondary cellsThermodynamicsElectrical battery

The invention discloses a water cooling plate which comprises a plurality of water cooling parts arranged continuously, the adjacent water cooling parts are fixedly connected, and any water cooling part comprises a plate body which is of a hollow box body structure with openings in the two ends; two side plates which are oppositely arranged at the two ends of the plate body, wherein a sealed water cooling cavity is formed by the two side plates and the plate body; a plurality of shunting plates which divide the water cooling cavity into a plurality of shunting parts which are communicated with one another; two plug groups which are respectively arranged on the two side plates, wherein any plug group comprises a plurality of plugs which are arranged at intervals along the width direction of the plate body, and any plug is arranged between the side plate and the adjacent splitter plate. The number of the water cooling parts is selected according to different battery lengths, so that the length of the water cooling plate is matched with the length of the battery needing heat dissipation, the flexibility is high, and the circulation path and the water flow direction of cooling water are changed by adjusting the number of the plugs in the water cooling parts and the arranged positions, so that the heat dissipation effect of the water cooling plate is adjusted.

Owner:东时(武汉)新能源科技有限公司

Furnace wall gun copper box cooling method

InactiveCN103604298AImprove cooling effectCause thermal shutdownFurnace coolingWater leakageCooling effect

Disclosed is a furnace wall gun copper box cooling method. The method is characterized by including that (1) equipment improvement is performed on the side wall of a copper box of a furnace wall gun, in other words, at least two cooling pipes are welded to the inner side of an outer copper plate of the side wall of the copper box of the furnace wall gun, wherein each cooling pipe is provided with an air inlet and an air outlet, cooling pipe orifices in the middle of the side wall of the copper box are set as the air inlets, and cooling pipe orifices in the upper portion and the lower portion of the side wall of the copper box are set as the air outlets; (2) compressed air enters from the air inlets in the middle of the side wall of the copper box and is discharged from the air outlets in the upper portion and the lower portion of the side wall of the copper box, and cooling is performed via the compressed air under the pressure of 2.0-2.8MPa and with the flow more than or equal to 4000Nm3 / h. Cooling effect is regulated by increasing and decreasing the air circulation inlets and outlets and the air circulation speed. Thus, frequent water leakage caused by cooling of cooling water as well as long-time thermal shutdown and major potential safety hazards caused by water leakage are avoided.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

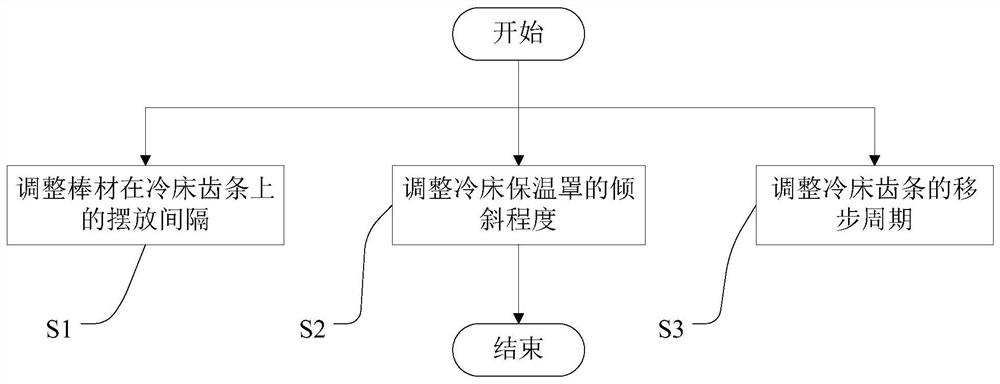

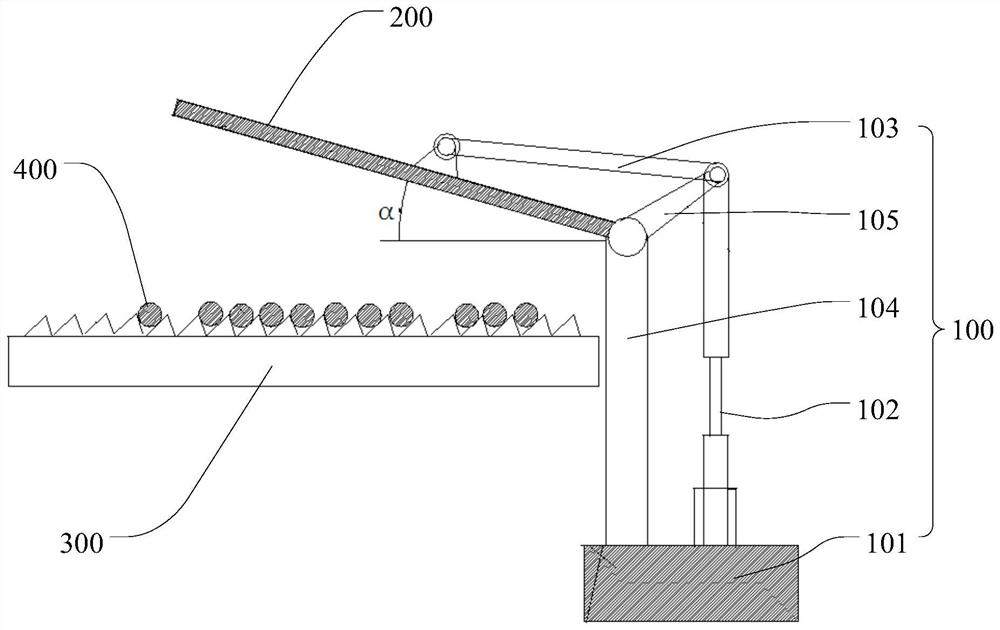

Bar cooling speed adjusting method and device and bar rolling method and system

PendingCN114289501ACooling Speed AdjustmentControl cooling rateCooling bedsMetal rolling arrangementsThermodynamicsHeat conservation

The invention discloses a bar cooling speed adjusting method and device and a bar rolling method and system. The bar cooling speed adjusting method comprises the steps that S1, the placing interval of bars on a cooling bed rack is adjusted; s2, the inclination degree of a cooling bed heat preservation cover is adjusted; and S3, the moving period of the cooling bed rack is adjusted. According to the bar cooling speed adjusting method provided by the invention, adjustment is carried out from three aspects of the placing interval of the bars, the inclination degree of the cooling bed heat preservation cover and the moving period of the cooling bed rack, so that the cooling speed of the bars is effectively controlled, the hardness value of the hot-rolled bars is controlled, and the requirement of downstream users on the hardness value of the hot-rolled bars is met.

Owner:SHANDONG IRON & STEEL CO LTD

Air feeding grille for beach vehicle

PendingCN107738572AAdjust cooling effectControl air intakeComponent optimizationRadiatorsEngineering

The invention discloses an air feeding grille for a beach vehicle. The waterproof air feeding grille includes a vertical plate, a transverse plate and a grid; the vertical plate is divided into a leftvertical plate body and a right vertical plate body, the left vertical plate body is internally provided with a first groove and a second groove, the right vertical plate body is provided with a cylindrical groove, the first groove is communicated with the second groove through a circular hole, and the right side of the second groove runs through the inner wall of the right side of the vertical plate; the transverse plate is internally provided with a square groove, and a square hole is formed in the lower portion of the left end of the square groove and runs through the lower wall of the square groove to be connected with the first groove; a rotating rod is arranged in the square groove, the first groove and the left end of the square groove are both internally provided with gears, and the gear in the square groove is fixedly connected with the left end of the rotating rod; the gear of the first groove is fixedly connected with the left end of a connecting rod, and the right end of the connecting rod penetrates through the grid and extends into the cylindrical groove; a spline matched with the corresponding gear is fixed at the front side of a square rod and is in meshed connection with the gear, and therefore an angle adjusting function of the grid is achieved.

Owner:重庆福发动力科技有限公司

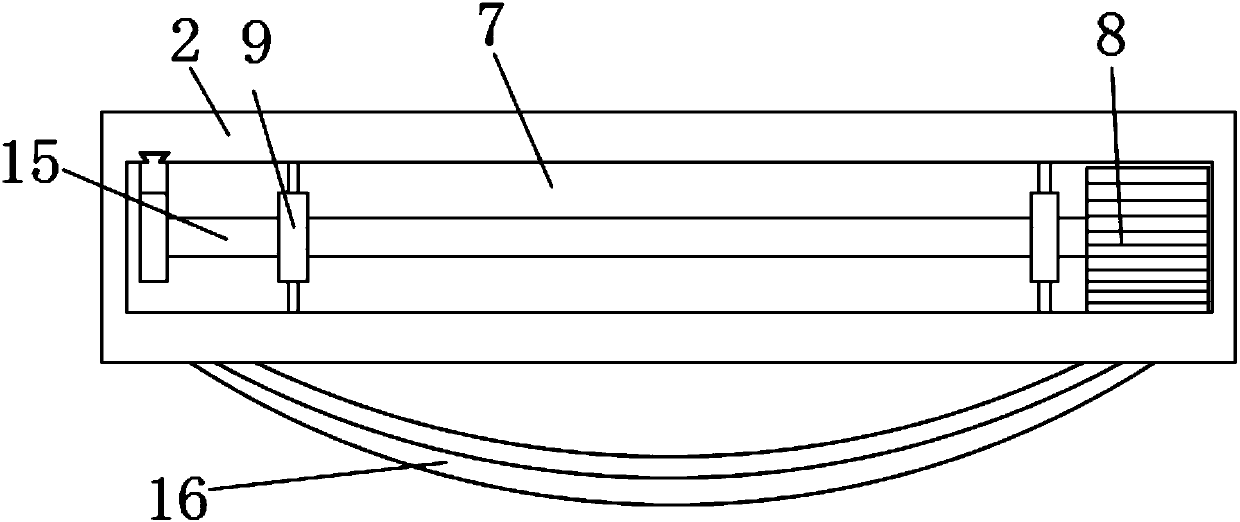

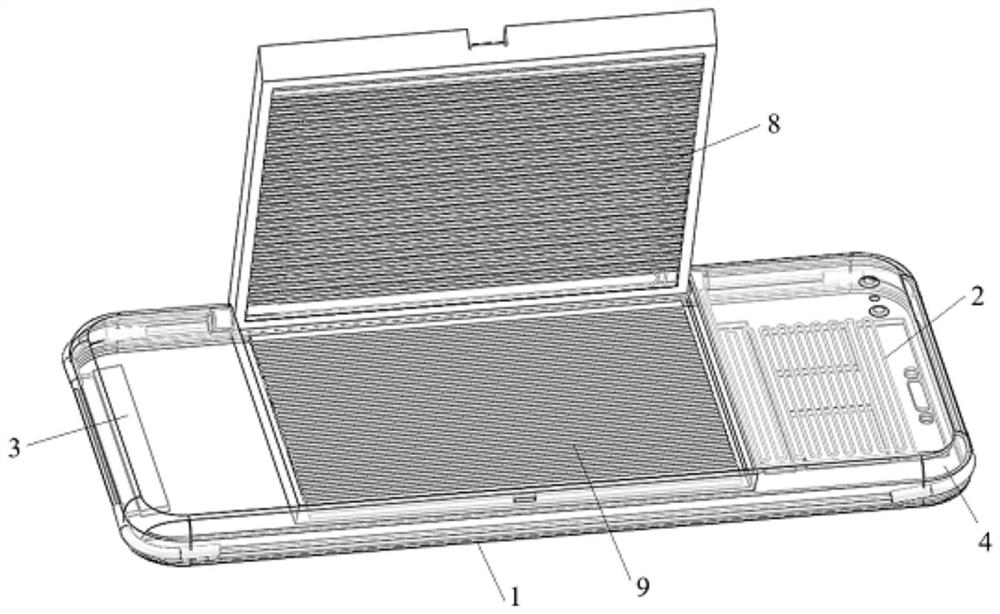

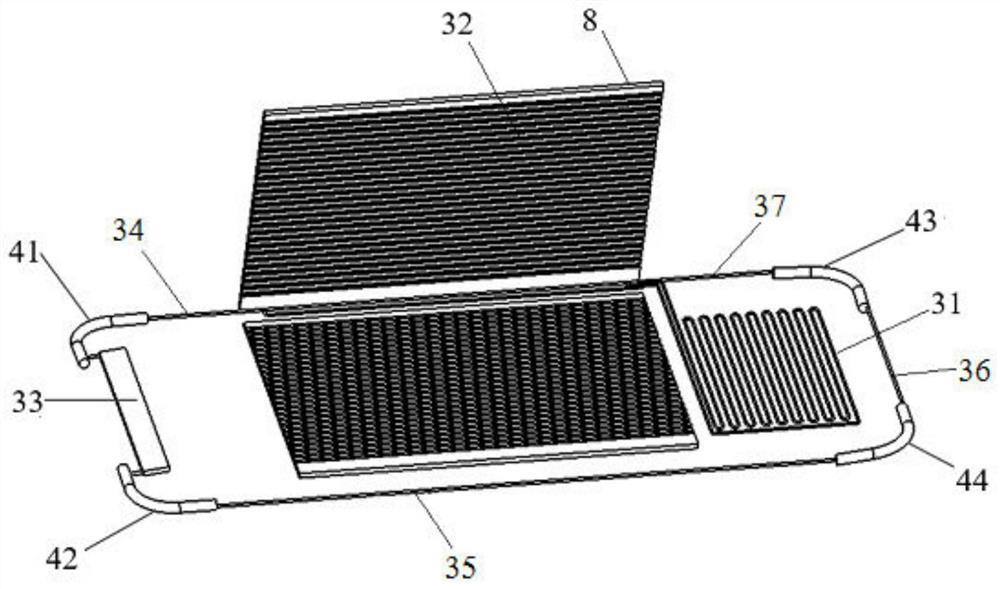

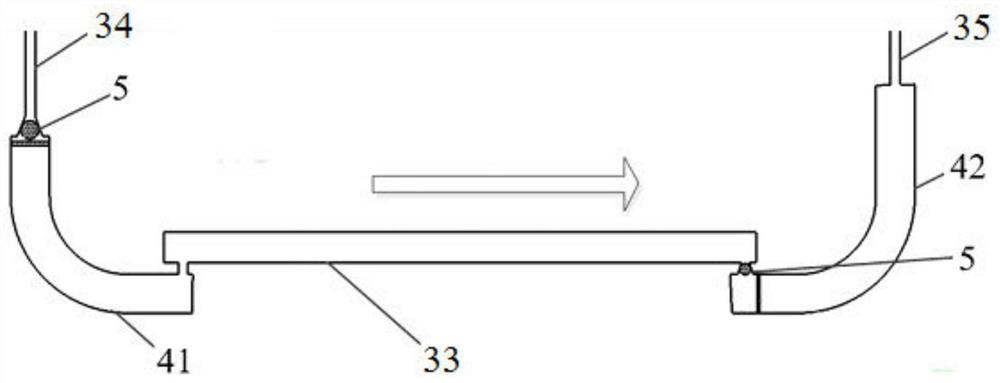

Cooling system and terminal equipment

InactiveCN109640606BReduce the temperatureImprove cooling effectCooling/ventilation/heating modificationsThermodynamicsTerminal equipment

The invention provides a heat dissipation system and terminal equipment, and the heat dissipation system is applied to the terminal equipment, and comprises a circulation pipe and a one-way valve installed on the circulation pipe, wherein the circulation pipe is used for containing a heat exchange medium and allowing the heat exchange medium to flow circularly. The circulation pipe comprises a heat dissipation section and at least one air bag section, wherein the air bag sections are made of elastic materials. The one-way valve is used for enabling the heat exchange medium to flow circularly in one direction. The internal air pressure is changed by pressing the air bag sections, so as to promote the directional flowing of the heat exchange medium in the circulation pipe, thereby improvingthe heat dissipation efficiency. In addition, the heat dissipation effect can be adjusted at any time according to conditions during use, and the control mode is flexible, simple and convenient.

Owner:BOE TECH GRP CO LTD +1

Integrated heating and cooling plate for glass hot bending

The invention discloses an integrated heating and cooling plate for glass hot bending. The integrated heating and cooling plate comprises a plate body and a cooling pipe, wherein pipe holes are formedin the plate body, and the cooling pipe is arranged in the pipe holes to be connected with the plate body. An existing simple heating plate is improved, the cooling pipe is added, cooling inside thecooling pipe is optimized through the structure of outer pipes and inner pipes, so that the cooling process is controllable, the problem of energy consumption during proofing in the glass hot bendingprocess is solved, the production efficiency can be improved, and the plate has great significance in the actual production process.

Owner:黑龙江特通电气股份有限公司

A vortex tube refrigeration device with sleeve-type cold flow outlet

A vortex tube refrigeration device with a sleeve-type cold flow outlet is characterized in that it comprises a vortex chamber, a hot end pipe, and a sleeve-type cold-end pipe; The end pipes are connected; the sleeve type cold end pipe is a mutually coaxial rotary body flow channel composed of a central pipe and at least one layer of outer sleeves which are all communicated with the vortex chamber. Compared with the traditional vortex refrigerating tube, the present invention can draw out airflows with different temperatures from different radii of the outlet of the cold end of the vortex chamber, and switch different sources of cold air with the change of the working conditions of the vortex tube refrigerating device, and pass Adjust the flow of each cold air passage to adjust the working state of the vortex tube to adjust the cooling effect.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

An intelligent converter cooling system and intelligent cooling control method

ActiveCN104901557BReduce external noise pollutionAdjust cooling effectAc-dc conversionCooling/ventilation/heating modificationsControl signalSolenoid valve

An intelligent converter cooling system and an intelligent cooling control method, the first cooling loop in the system includes a first variable pump that flows through a first inverter and a first rectifier and forms a loop through pipelines, a first cooling pipe , the first cooling medium tank, the first solenoid valve, the first heat exchanger, the second cooling circuit includes the second variable pump that flows through the second inverter and the second rectifier and forms a circuit through the pipeline, and the second cooling pipe , the second cooling medium tank, the second solenoid valve, the second heat exchanger, the first cooling circuit and the second cooling circuit all flow through the central control valve group; the control component controls the central control valve group through the monitoring signal of the sensor component to The switching of the working state of the first cooling circuit and / or the second cooling circuit is completed. The method is performed based on the system described above. The invention has the advantages of simple principle, good cooling effect, good energy saving effect and the like.

Owner:ZHUZHOU CSR TIMES ELECTRIC CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com