A primary mold vertical cooling mold

A mold and cavity technology, applied in the field of glass bottle molds, can solve the problems of barbs on the bottle surface, uneven heat dissipation, low heat dissipation efficiency at the glass neck, and achieve the effects of improving heat dissipation efficiency, improving product quality, and improving molding speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

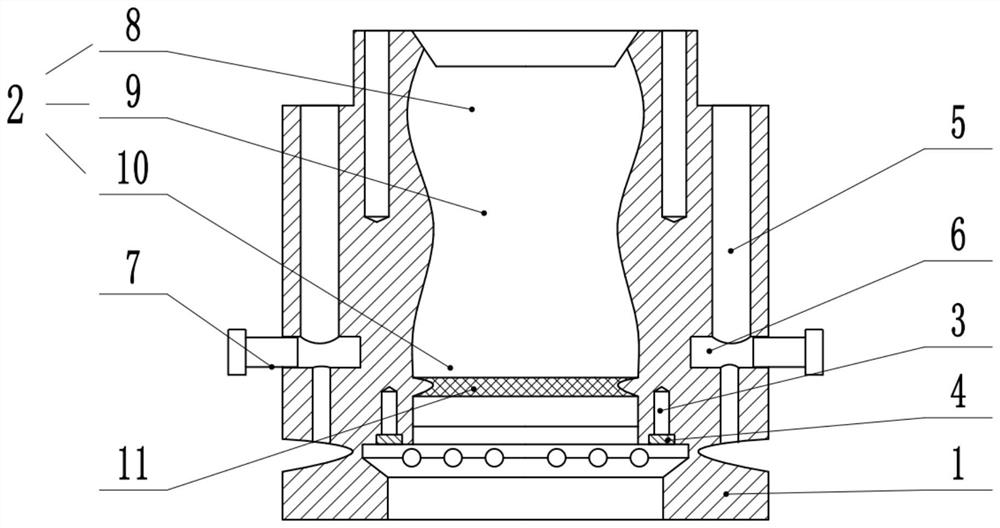

[0024] Basic as attached figure 1 Shown: a blank mold vertical cooling mold, including two semi-primary molds 1 with the same size and structure, and a semi-cavity is opened on the side wall of the semi-primary mold 1. Two half-blank molds 1 can be closed towards each other, and two half-cavities 2 form a complete cavity 2 . The inner wall near the bottom of the cavity 2 is provided with a thermal insulation hole 3, and the thermal insulation hole 3 is a blind hole. And the end of the heat preservation hole 3 is blocked with a heat conduction block 4 , and the surface of the heat conduction block 4 facing outward is coplanar with the inner wall surface of the cavity 2 . The top surface of half blank mold 1 has vertical cooling hole 5, and the axial direction of vertical cooling hole 5 is parallel to the axial direction of half blank mold 1, and the upper and lower ends of vertical cooling hole 5 are identical with half blank mold 1. The upper and lower ends of the vertical c...

Embodiment 2

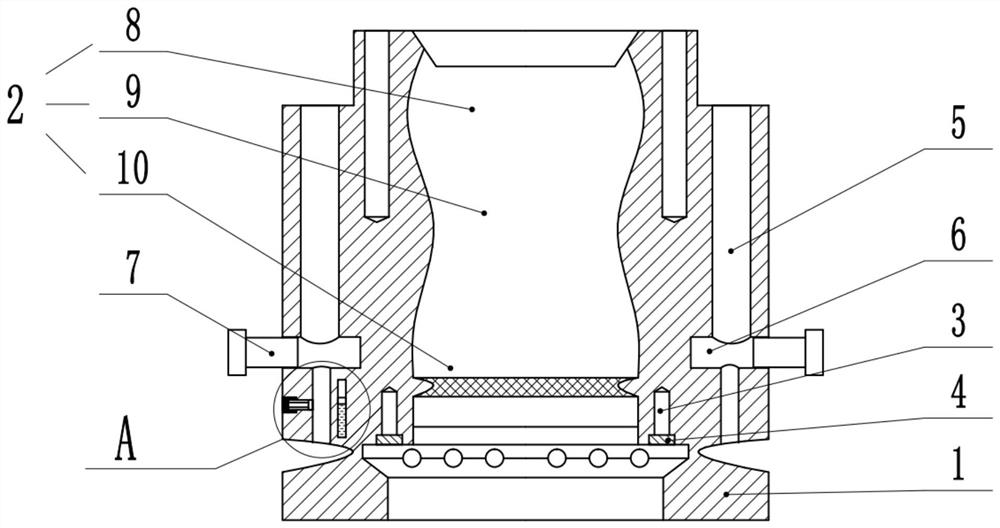

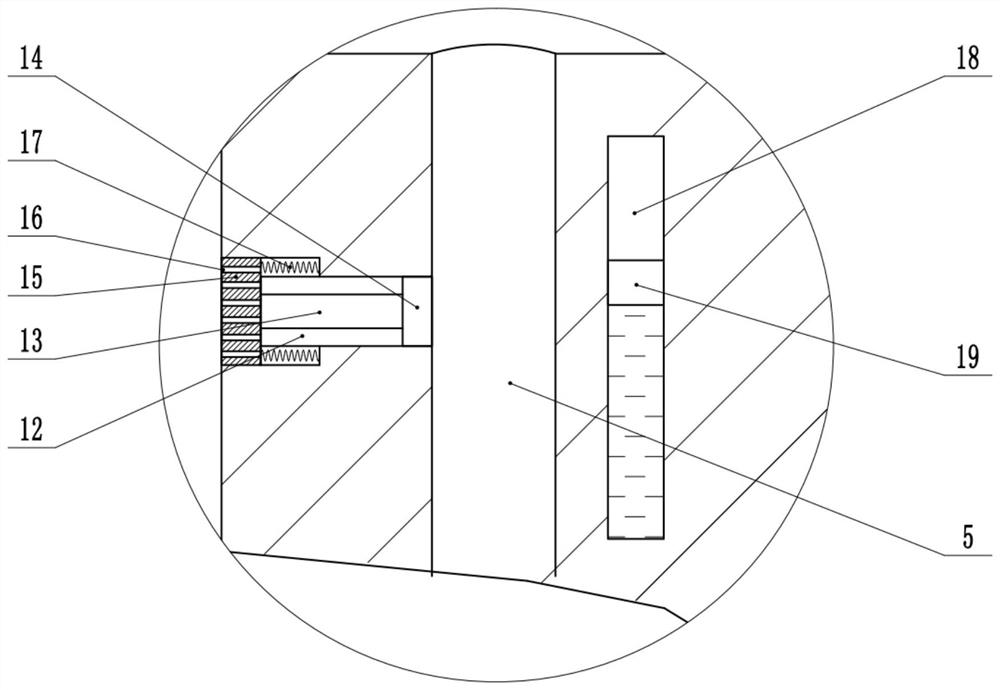

[0028] The difference between this embodiment and the first implementation is that, as attached figure 2 with attached image 3 As shown, the mold of this technical solution is made of non-magnetic high-temperature-resistant alloy steel. There is a ventilation hole 12 on the outer wall of the semi-basic mold 1, and the ventilation hole 12 is connected to the vertical cooling hole 5. A closing rod 13 is slidably connected to the ventilation hole 12, and a sealing block 14 is welded and fixed on the right end of the closing rod 13, and the outer wall of the sealing block 14 is wrapped. There is a magnet layer, and the outer contour of the airtight block 14 seals the vent hole 12. The left end of closing lever 13 is welded and fixed with reset block 15, and reset block 15 surface evenly has some whistle holes 16, is fixedly connected with stage clip 17 between reset block 15 and the semi-basic mold 1 outer wall. The semi-primary mold 1 has a temperature measuring hole 18 in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com