An intelligent converter cooling system and intelligent cooling control method

A cooling system and converter technology, applied in cooling/ventilation/heating transformation, conversion of AC power input to DC power output, output power conversion device, etc., can solve the problem of low cooling efficiency, inability to adjust the cooling effect, and uneconomical and other problems, to achieve high cooling efficiency, improve reliability and service life, and reduce energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

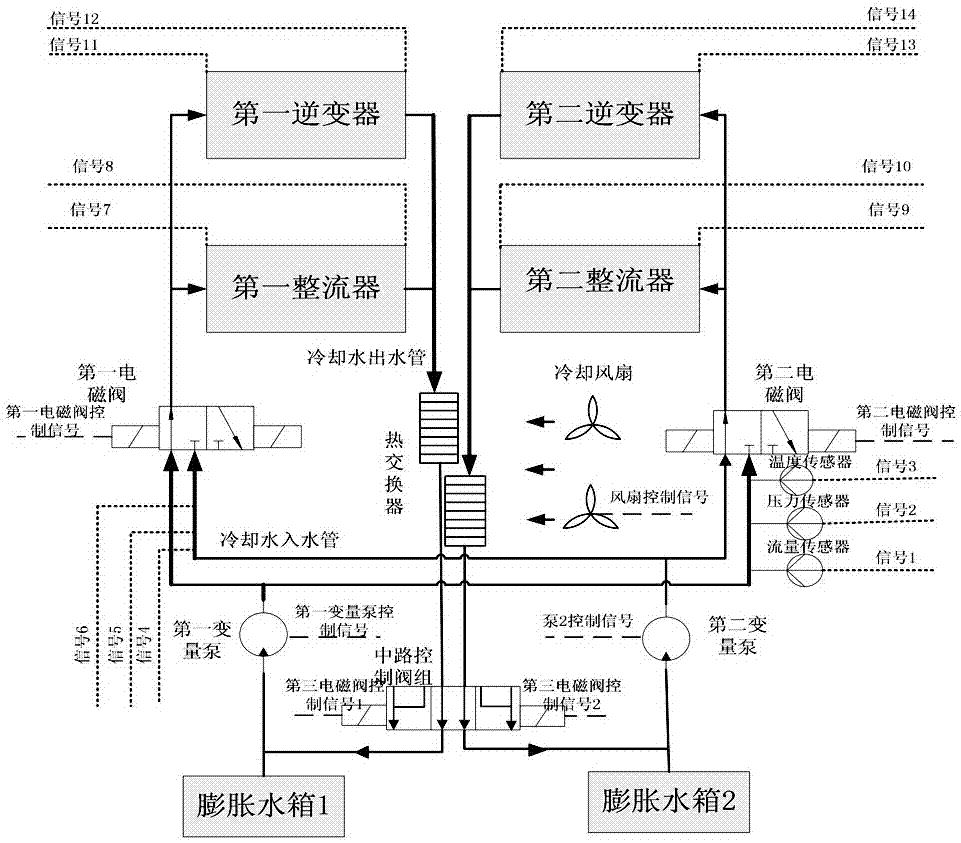

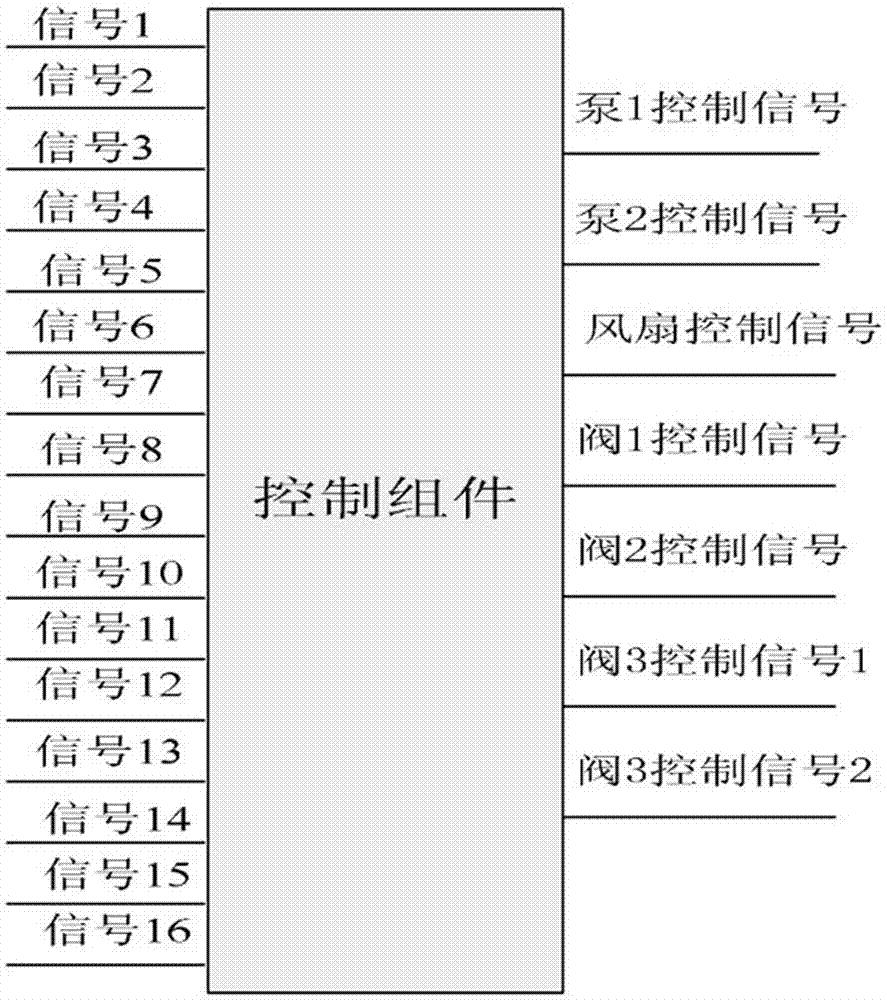

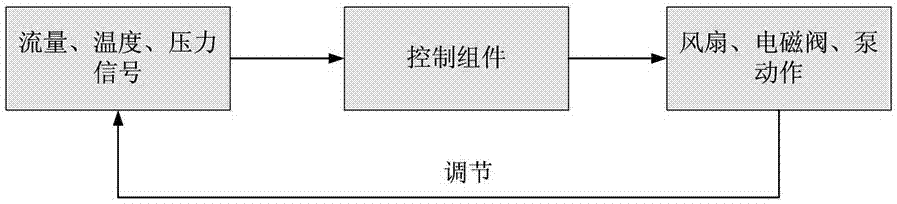

[0035] The intelligent converter cooling system of the present invention includes a control assembly, a sensor assembly, a first cooling circuit, a second cooling circuit, and a central control valve group, and the first cooling circuit includes a flow through the first inverter and the first rectifier And the first variable pump, the first cooling pipe, the first cooling medium tank (expansion tank), the first electromagnetic valve, and the first heat exchanger are formed into a circuit through the pipeline. The second cooling circuit includes the flow through the second inverter. The inverter and the second rectifier form the second variable pump, the second cooling pipe, the second cooling medium tank (expansion tank), the second solenoid valve, and the second heat exchanger through the pipeline. The first cooling circuit and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com