Integrated heating and cooling plate for glass hot bending

An integrated, cooling plate technology, applied in glass forming, glass reshaping, glass manufacturing equipment, etc., can solve the problem of long cooling time in single precision furnace production, achieve low energy consumption of equipment and reduce energy consumption , the effect of ensuring integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] In this embodiment, the cooling fluid used is low-temperature gas.

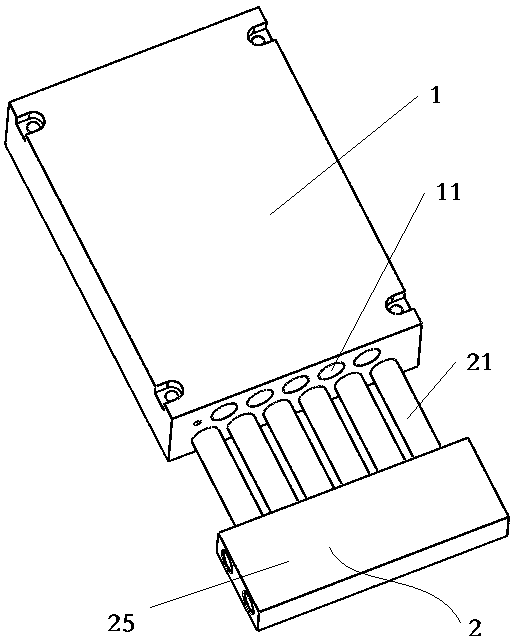

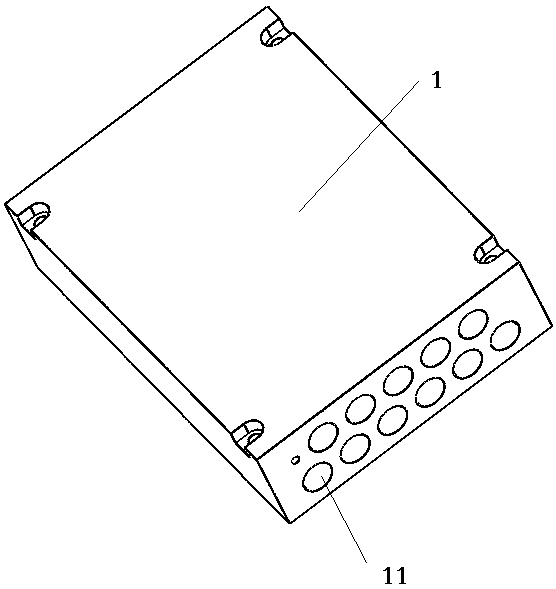

[0027] The integrated heating and cooling plate for glass hot bending has two parts: a plate body 1 and a cooling pipe 2, wherein the plate body 1 contains two layers of tube holes 11, and the diameter of the tube holes 11 matches the size of the existing heating tube. One layer of pipe holes 11 is used for placing heating pipes, and the other layer of pipe holes 11 is used for placing the outer pipe 21 of cooling pipeline 2 . Bolt holes for fixing are also provided outside the board body 1 .

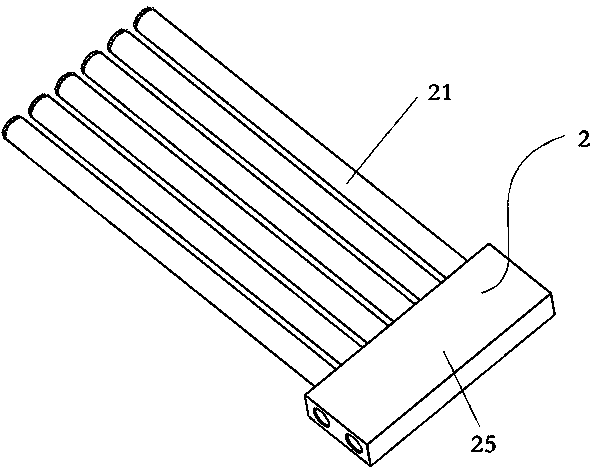

[0028] The cooling pipeline 2 part includes a nozzle assembly 25, an inner pipe 22 and an outer pipe 21. The tank mouth assembly is provided with an inner pipe connection 23 and an outer pipe connection 24. There are a plurality of inner pipe connections 23 with The station that the inner pipe 22 is connected, and there are also a plurality of stations connected with the outer pipe 21 in the outer pipe connecti...

Embodiment 2

[0034] In this embodiment, the difference from Embodiment 1 is that the cooling medium used is cooling gas, and the cooling method is input from the inner pipe connecting channel 23 and output from the outer tube connecting channel 24 .

[0035] During the cooling cycle, the cooling gas is injected into each inner tube 22 from the inner tube connecting channel 23, and when the cooling gas reaches the end of the inner tube 22, a part of the gas will flow into the outer tube 21 through the gap between the arc columns, and the other part The air will directly contact the end of the outer tube 21 through the end of the opening. Due to the effect of air pressure, this part of the cooling gas will move to the connecting channel 24 of the outer tube, and take away the heat on the plate body 1 during the moving process. Thus, the cooling efficiency is improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com