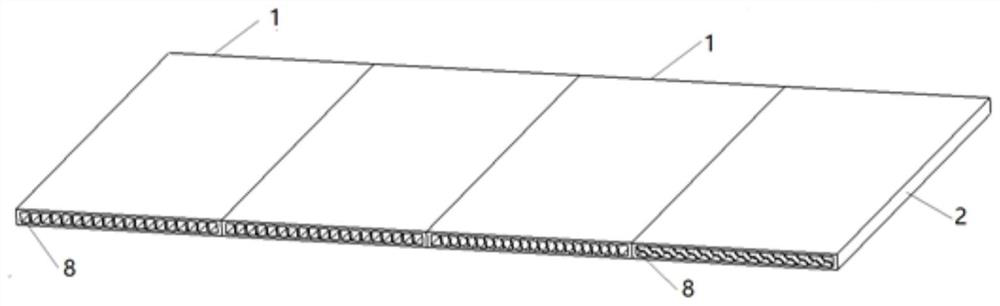

Water cooling plate

A water-cooled plate and water-cooled technology, which is applied in the cooling combination arrangement of power units, electric vehicles, battery/fuel cell control devices, etc., can solve the problems of high tooling cost, high comprehensive cost and high cost, and achieve low mold cost, The effect of low comprehensive cost and high flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

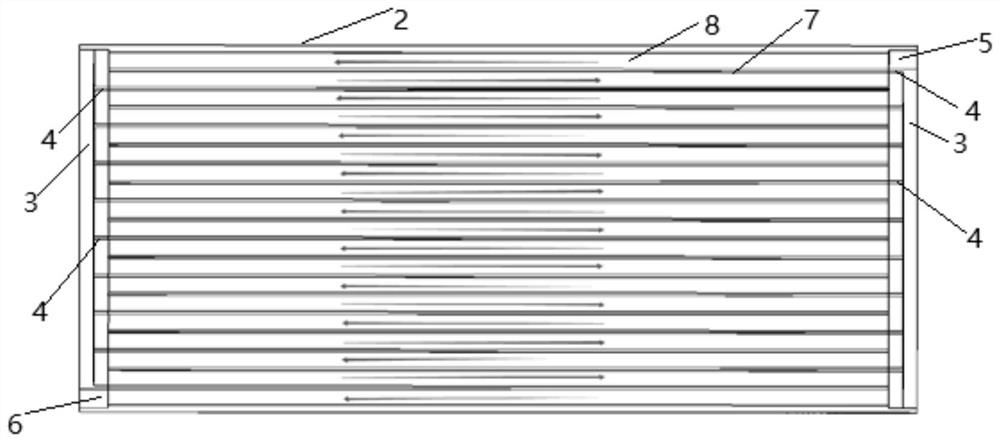

Embodiment 1

[0053] like figure 2 As shown, the number of plugs 4 on the two side panels 3 of this water cooling portion 1 is the same, and a split plate 7 is disposed at a time separation plate 7 is provided, and one end of any of the buses 7 is fixed to the plug 4. Connection, the other end does not set the plug 4, where one end of the splitter plate 7 adjacent the inlet hole 5 is fixed to the plug 4, that is, the cooling water is blocked from the inlet hole 5 after the blocking of the plug 4 will only flow to the first A split portion 8 and the plug 4 on the second shunting plate 7 blocks flow to the second shunt portion 8, so that the cooling water is circulated in the plurality of shunt portions 8, corresponding to the water-cooled portion 1 The position of the battery is sequentially dissipated.

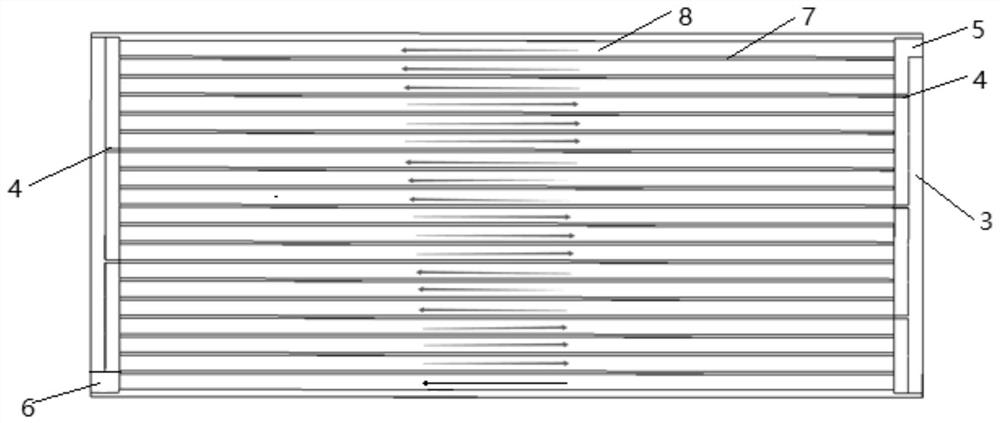

Embodiment 2

[0055] The number of plugs 4 on the two side panels 3 of this water cooling portion 1 and the position of the setting, such as image 3 As shown in the three adjacent shunt portions 8 as a set, the cooling water flows from the inlet hole 5 to the three adjacent shunt portions 8, and flows at the same time after reaching the next set of shunt portions 8 In the three shunt portions 8 of the next group, i.e., the water-cooled portion 1 can heat dissipate the position of the corresponding battery on the three adjacent shunt portions at the same time, and the heat dissipation area is more good.

[0056] In another technical solution, the plug 4 of the adjacent two water-cooled portions 1 is the same or different.

[0057] In the present technical solution, since the number of plugs 4 on the water-cooled portion 1 affects its heat dissipation effect, that is, the position of the cell corresponding to the adjacent two water-cooled portion 1 on the water cooled plate. The heat dissipation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com