Ultraviolet drying machine having cooling function and cooling control method

A UV and dryer technology, used in devices for coating liquids on surfaces, pretreatment surfaces, coatings, etc., can solve problems affecting product quality, and achieve the effects of lowering temperature, lowering product temperature, and optimizing the cooling effect of exhaust air

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements.

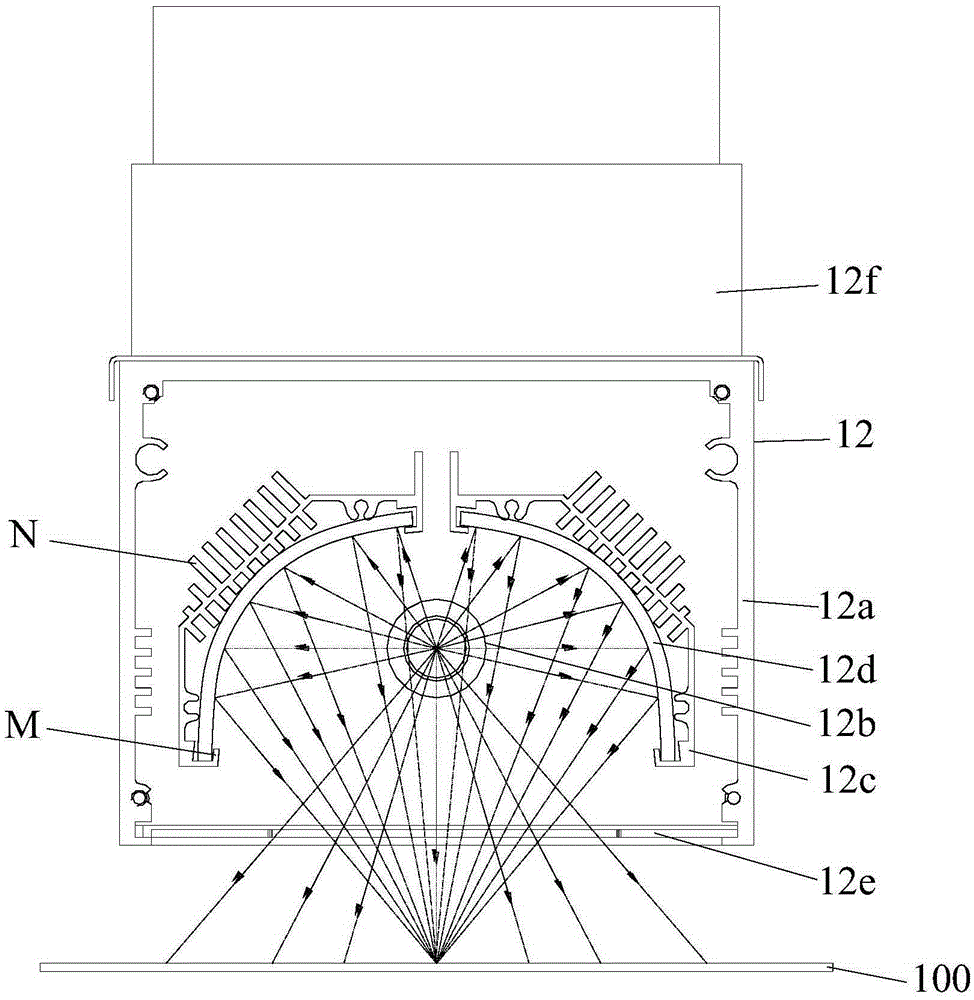

[0031] Please refer to Figure 1-6 , The described UV drying machine with cooling function includes a machine platform, which is composed of an upper seat 1 and a lower seat 2, and a conveyor belt (not shown) is provided at the junction of the lower seat 2 and the upper seat 1.

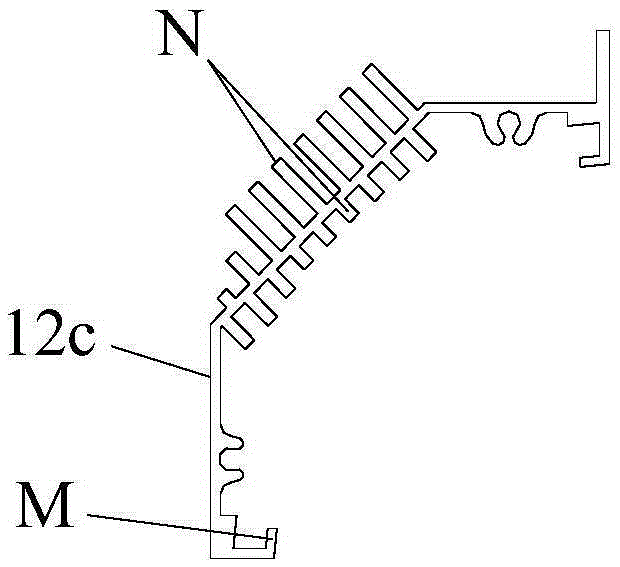

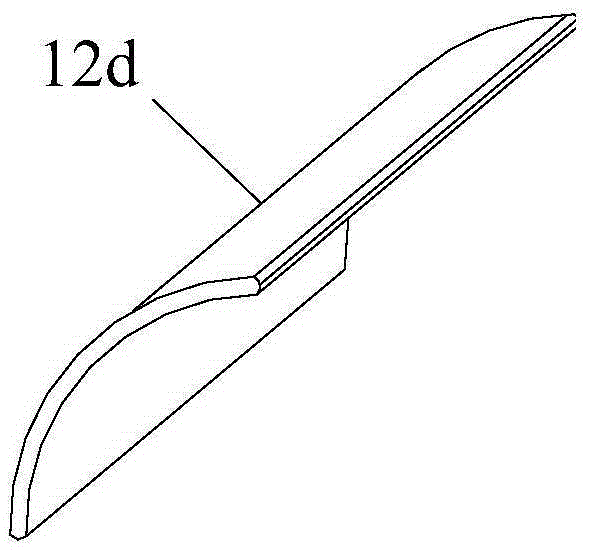

[0032] It is further illustrated that the upper seat 1 is provided with a UV curing channel 11 arranged along its longitudinal direction, and a plurality of UV lamp groups 12 and a plurality of air knife groups 13 are arranged at intervals in the UV curing channel 11, and the air knife group 13 and UV lamp groups 12 are alternately distributed in the UV curing channel 11 and are installed on the top wall of the UV curing channel 11. The top of the upper base 1 is provided with a cold wind blower 14 and a cold wind collecting hood 15 connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com