Flexible substrate real-time cooling device for reel-to-reel magnetron sputtering coating system

A magnetron sputtering coating and flexible substrate technology, applied in sputtering coating, ion implantation coating, vacuum evaporation coating, etc., can solve problems such as unfavorable film growth, affecting coating performance, and substrate temperature rise , to achieve the effect of low equipment requirements, simple structure, and small space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

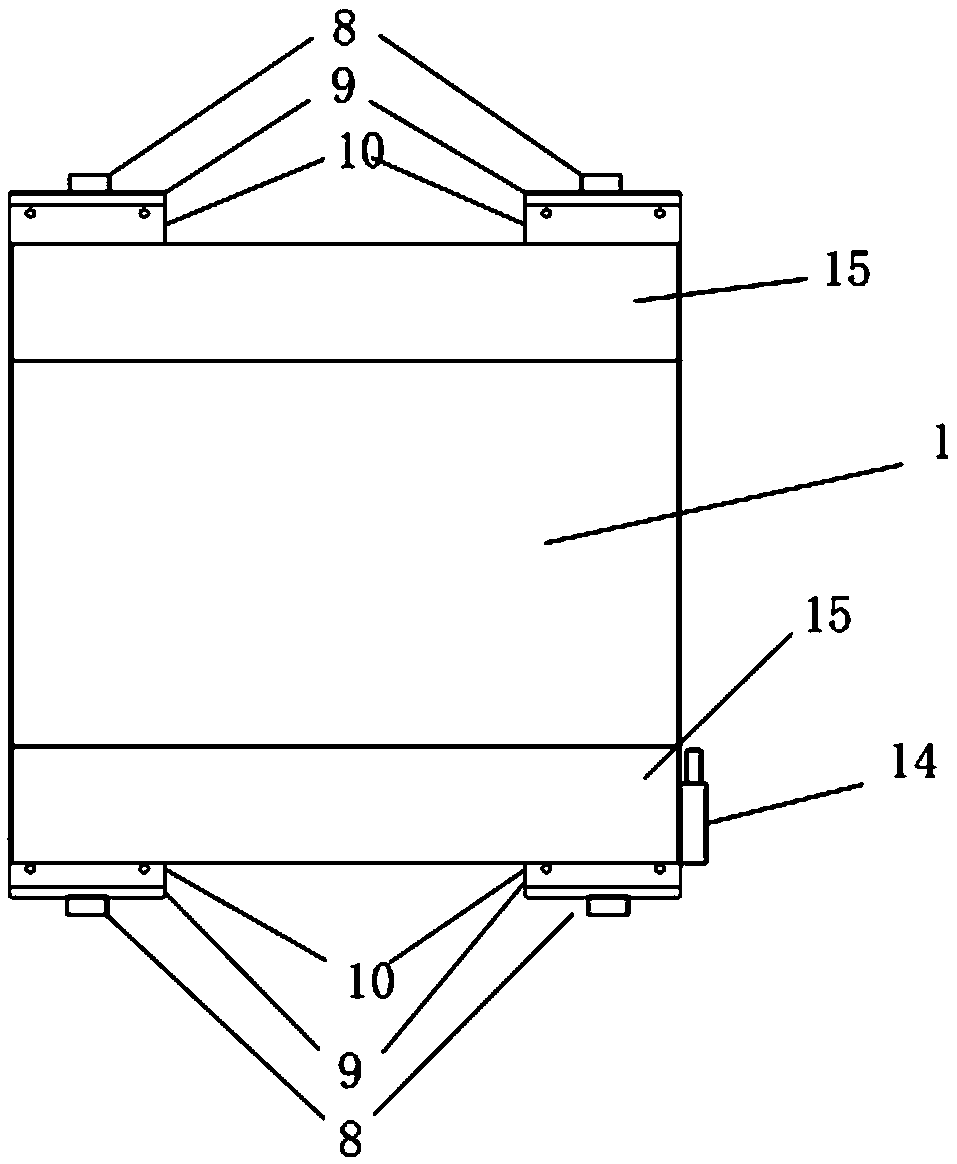

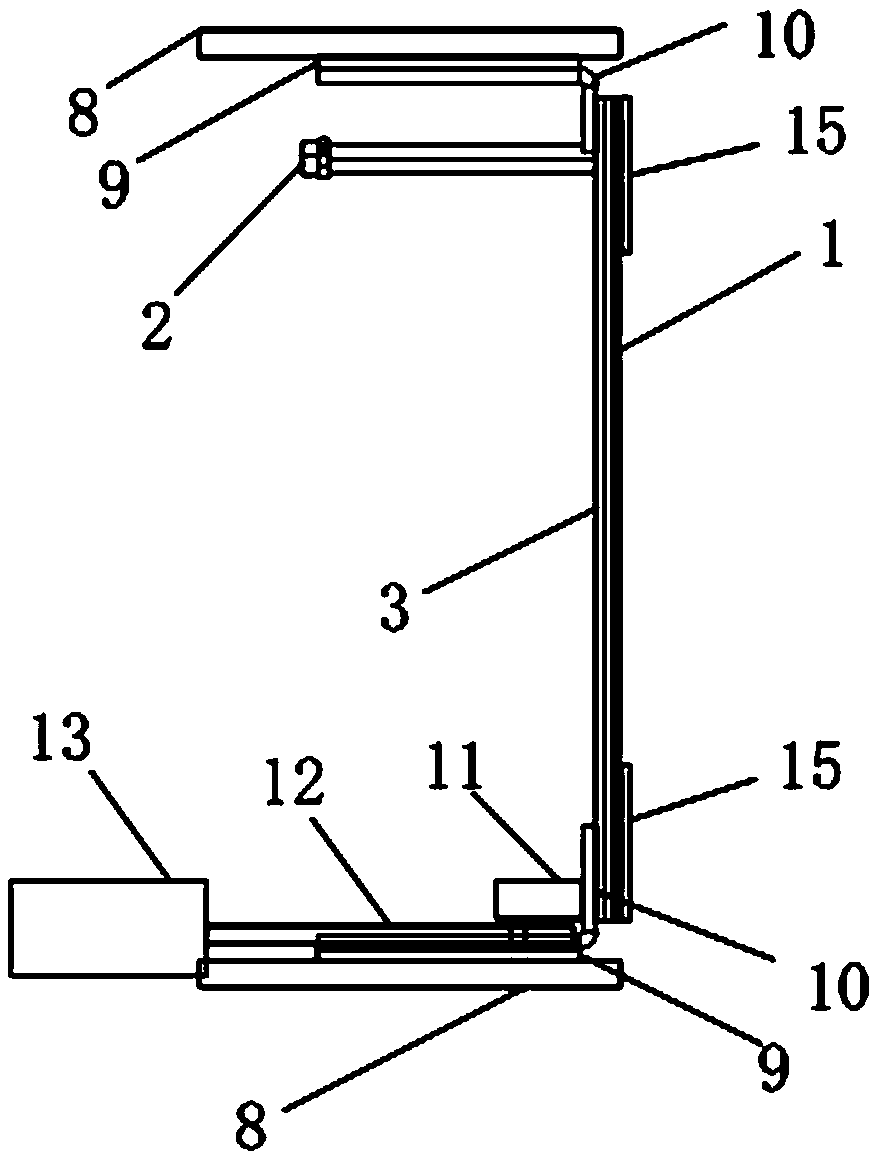

[0026] In the present invention, a water cooling screen is mainly made of a cooling plate and a back plate. The water cooling screen is different from the traditional water cooling plate with a flat surface in appearance, and the surface in contact with the substrate is an arc surface. This design can provide a Better contact and bonding with the water-cooled screen does not affect the stability of the substrate tension, as attached image 3 shown. When the substrate passes through, it is in contact with its arc-shaped surface, and the temperature of the water-cooled screen drops through the circulation cooling of the internal cooling water, so as to achieve the purpose of cooling the substrate.

[0027] As shown in the figure, the present invention is mainly composed of a cooling plate, a back plate, a set of position moving devices and a pair of baffles. The back of the cooling plate is slotted for guiding cooling water and arranging rubber rings for sealing. curved surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com