Furnace wall gun copper box cooling method

A cooling method and furnace wall technology, which is applied in the field of metallurgy, can solve problems such as cracks on the side wall of copper boxes, water leakage, uneven cooling, etc., and achieve the effects of improving poor cooling effects, reducing losses, and reducing production heat shutdowns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

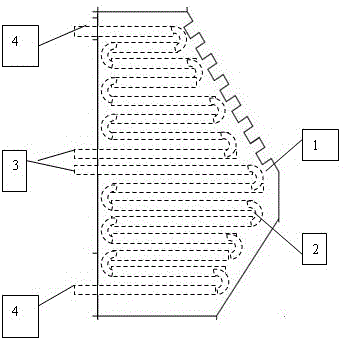

[0018] Example 1: 90t all-scrap stainless steel smelting, three sets of multifunctional furnace wall oxygen lances are installed on the furnace wall, 2# and 3# side walls are cooled by cooling water, and the 1# side wall is improved to be cooled by compressed air. That is, two copper tubes are welded on the 1# side wall 1 as the cooling tube 2, and the two copper tubes are bent into a serpentine shape and arranged horizontally on the 1# side wall ( figure 2 shown).

[0019] Compressed air enters from two air inlets 3 and is discharged through two air outlets 4, and cools the side walls of 2# and 3# through compressed air.

[0020] In this embodiment, compressed air is used to cool the 1# side wall, and one furnace (500 furnaces) cracks and leaks air once, and the cooling effect is obvious.

[0021] The implementation effect of the present invention is compared with the prior art: 90 tons of scrap steel and stainless steel are smelted, three sets of multifunctional furnace wa...

Embodiment 2

[0022] Embodiment 2: In this embodiment, 3 cooling pipes are used on the 1# side wall, that is, 3 air inlets and 3 air outlets are set; compressed air enters from 3 air inlets, and is discharged from 3 air outlets. Others are the same as in Embodiment 1.

[0023] In this embodiment, one furnace (500 furnaces) has 0 cracks and leaks, and the cooling effect is obvious.

[0024] The implementation effect of the present invention is compared with the prior art: 90 tons of scrap steel and stainless steel are smelted, three sets of multifunctional furnace wall oxygen lances are installed on the furnace wall, the side walls of 2# and 3# are cooled by cooling water, and the side wall of 1# copper box is cooled by water One furnace service (500 furnaces) cracked and leaked water 3 times. When the side wall is not cooled, one furnace (500 furnaces) burns through 4 times.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com