Vortex tube refrigerating device with sleeve type cold flow outlet

A refrigeration device, sleeve-type technology, applied in the refrigeration field of engineering thermophysics, can solve the problem that low-temperature fluid cannot be output and utilized independently

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

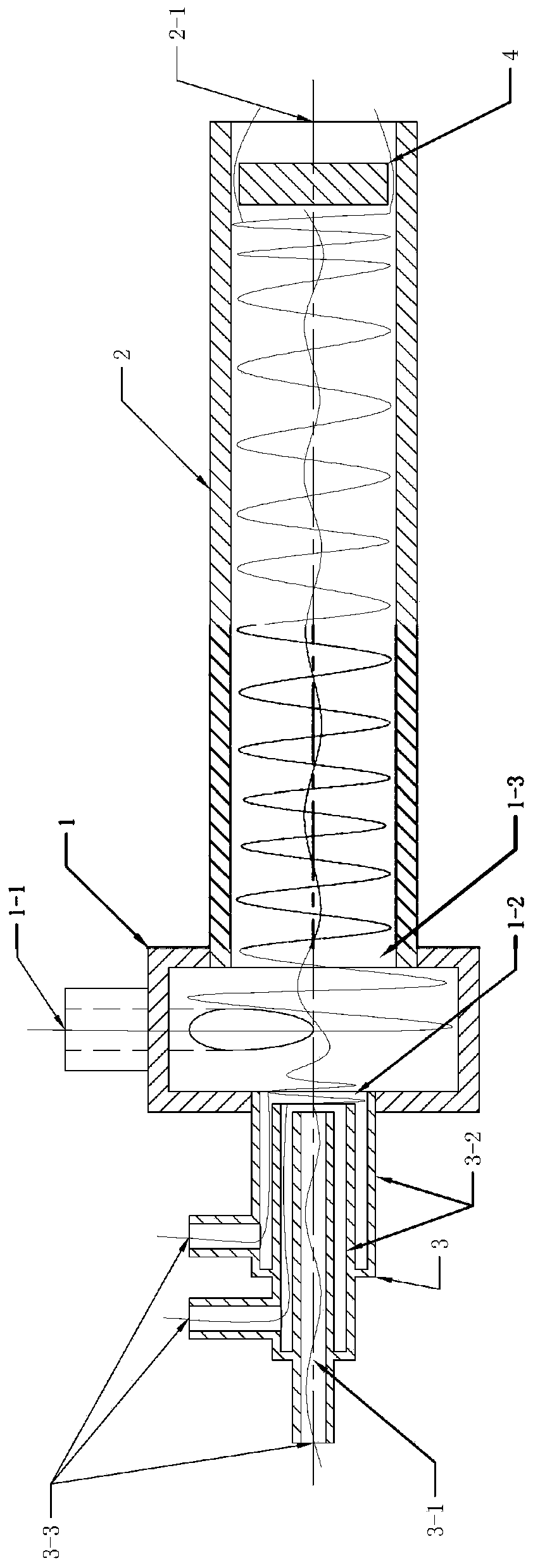

[0017] Such as figure 1 As shown, a vortex tube refrigeration device with a sleeve-type cold flow outlet includes a vortex chamber 1, a hot end tube 2, a sleeve-type cold end tube 3; The end pipe 3 and the hot end pipe 2 are connected; the sleeve-type cold end pipe 3 is mutually coaxially composed of a central pipe 3-1 and at least one outer sleeve 3-2 that are both in communication with the vortex chamber 1 Rotary body runner.

[0018] The central pipe 3-1 and the respective flow passages of the rotating body flow passage are connected to different cold fluid outlets 3-3 that can individually adjust their respective flow rates. The cold fluid generated by the operation of the vortex tube refrigeration device is respectively composed of these cold fluids. The outlets flow out at the same time, and under normal working conditions, the temperatures of the several cold fluids are different.

[0019] The vortex chamber 1 has a tangential fluid inlet 1-1 through which high-pressure fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com