Welding wheel

A welding machine, contact surface technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve problems such as reducing life, increasing current frequency and current intensity not optimal, increasing wheel heating, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The features, variants and various embodiments of the invention may be related to each other according to various combinations, since they are not mutually incompatible or exclusive. It will be possible to devise variants of the invention comprising only a set of the following features in isolation from other stated features, so long as this selection of features is sufficient to confer a technical advantage or differentiate the invention from the state of the art.

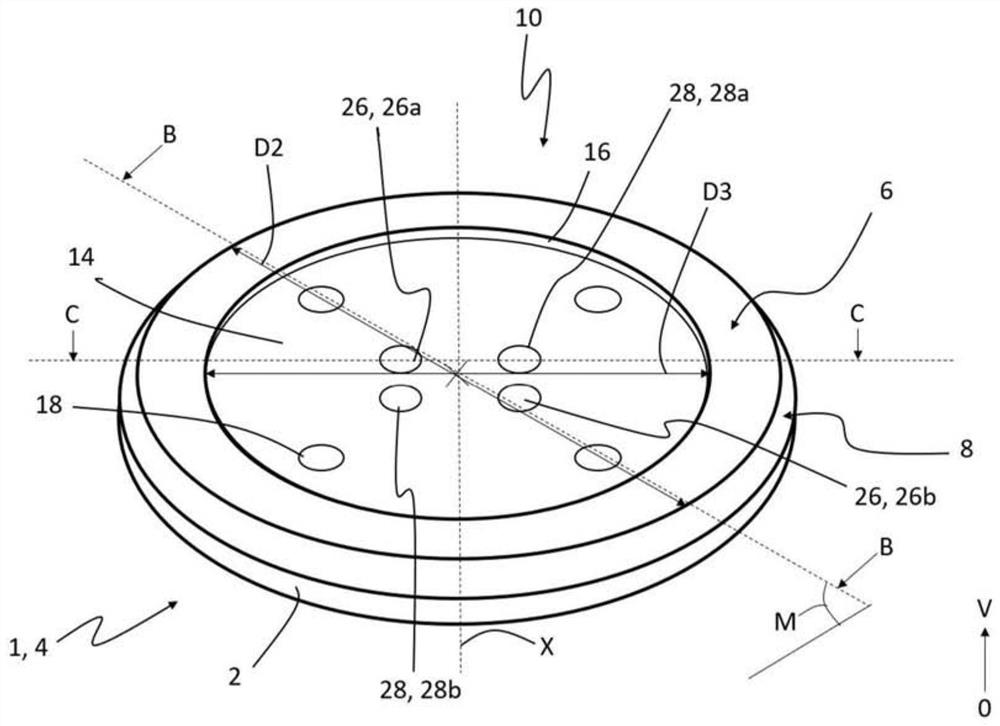

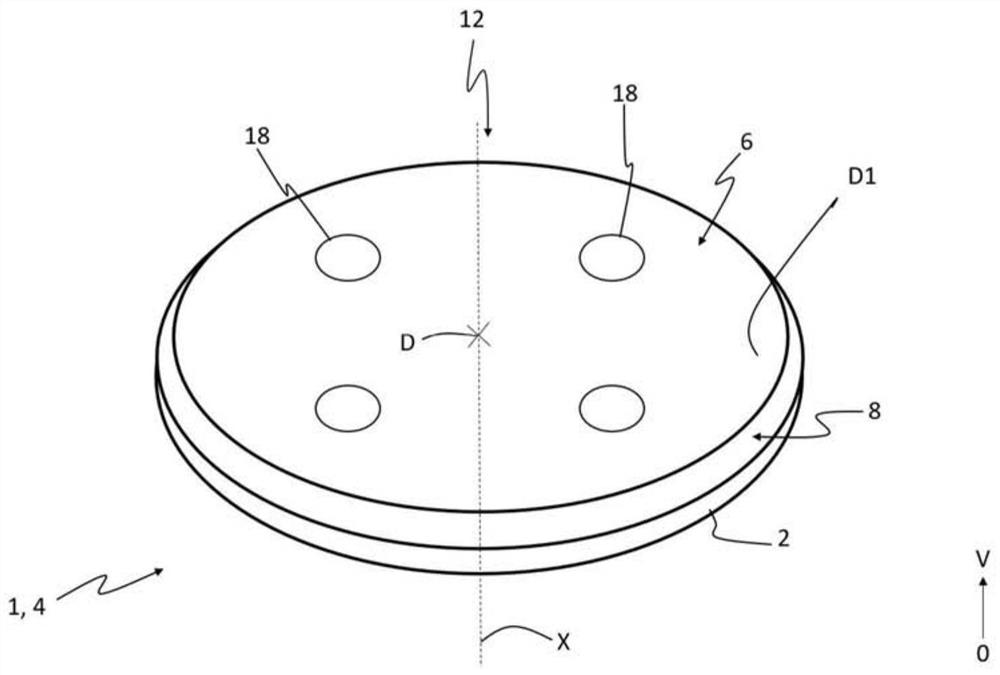

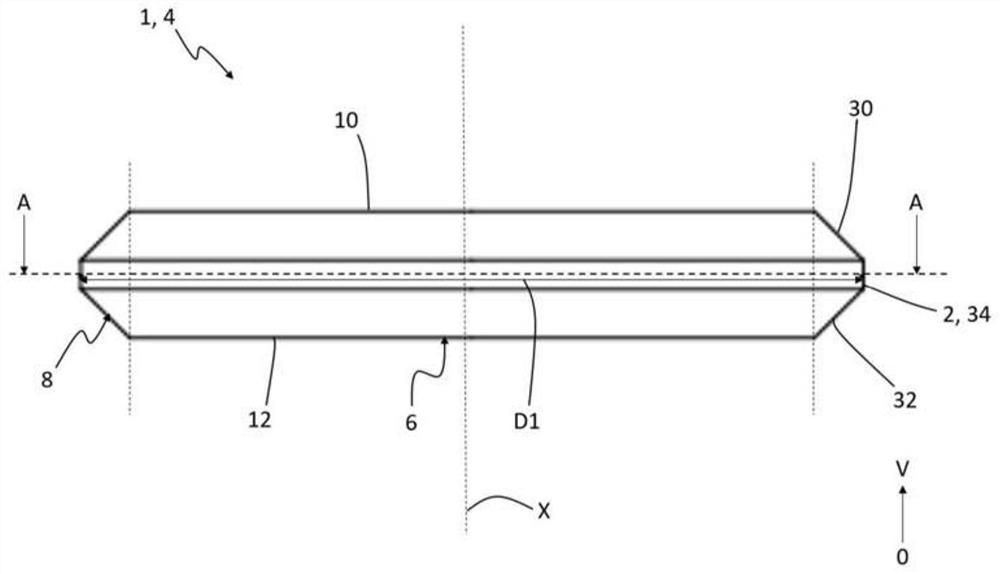

[0050] figure 1 A welding wheel 1 according to the invention is shown. The welding wheel 1 can be used to weld metal sheets together by continuous motion and spot welding. For this purpose, the welding wheel 1 is fixed to the welding machine (in Figure 7 Visible in ), its movement along the metal plate is carried out continuously at a speed greater than or equal to 2.5 m / min. Said movement of the welding machine thus ensures the movement of the wheel 1 and the diffusion of the current inside the wheel 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com