Sealing device for wheel bearings of motor vehicles

A sealing device and supporting device technology, which is applied to the sealing of the engine, the bearings of the rotating motion, the wheels, etc., can solve the problems of limiting the setting parameters of the centrifugal seal and the narrow structure space, and achieve the effect of simple and rapid assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

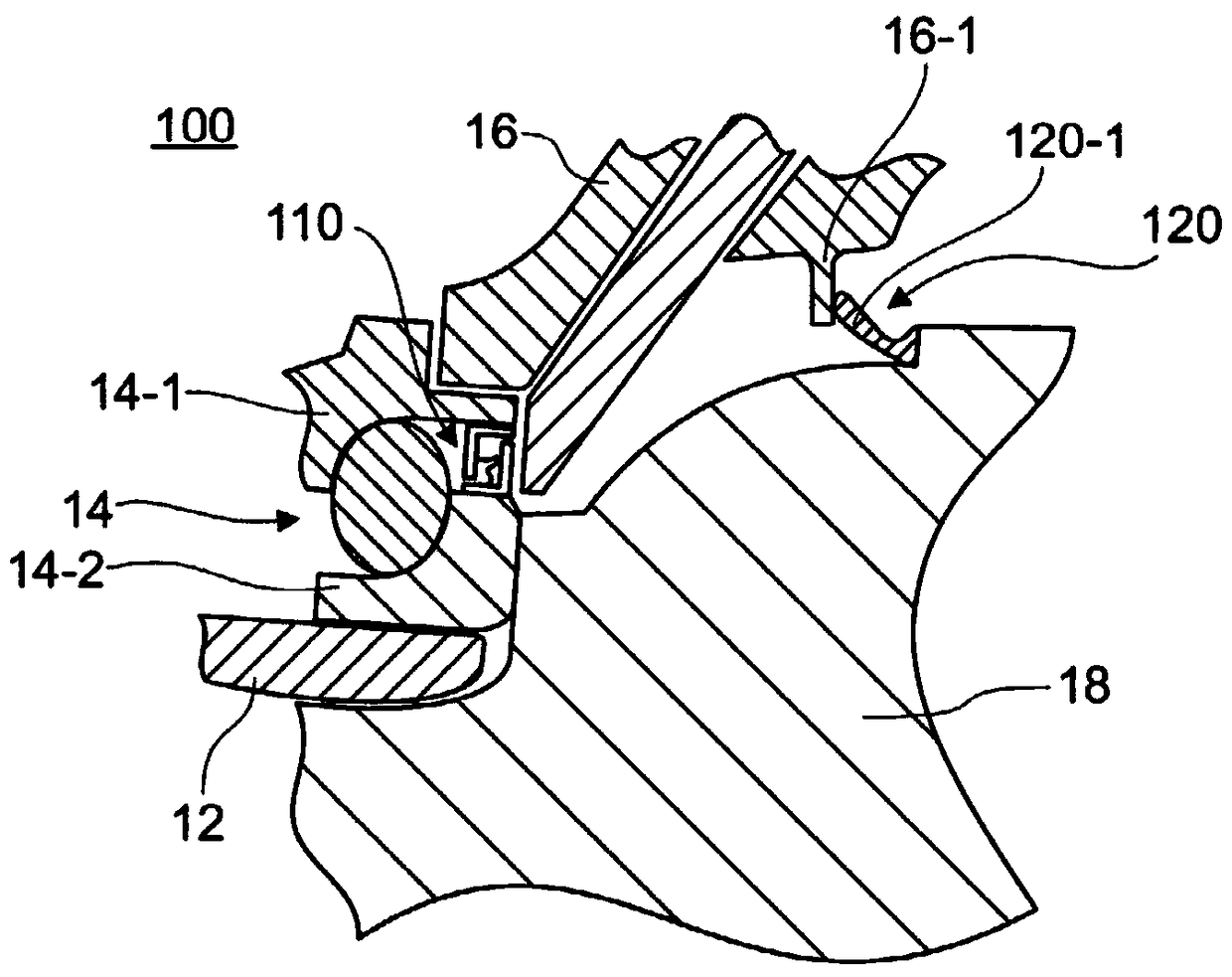

[0027] figure 1 A sealing device of a wheel bearing of a motor vehicle, indicated as a whole by the reference numeral 100 , is shown.

[0028] The wheel hub 12 is mounted rotatably on a wheel bearing housing 16 via a rolling bearing 14 in a known manner. The hub part 12 is itself in driving connection with a cardan shaft 18 .

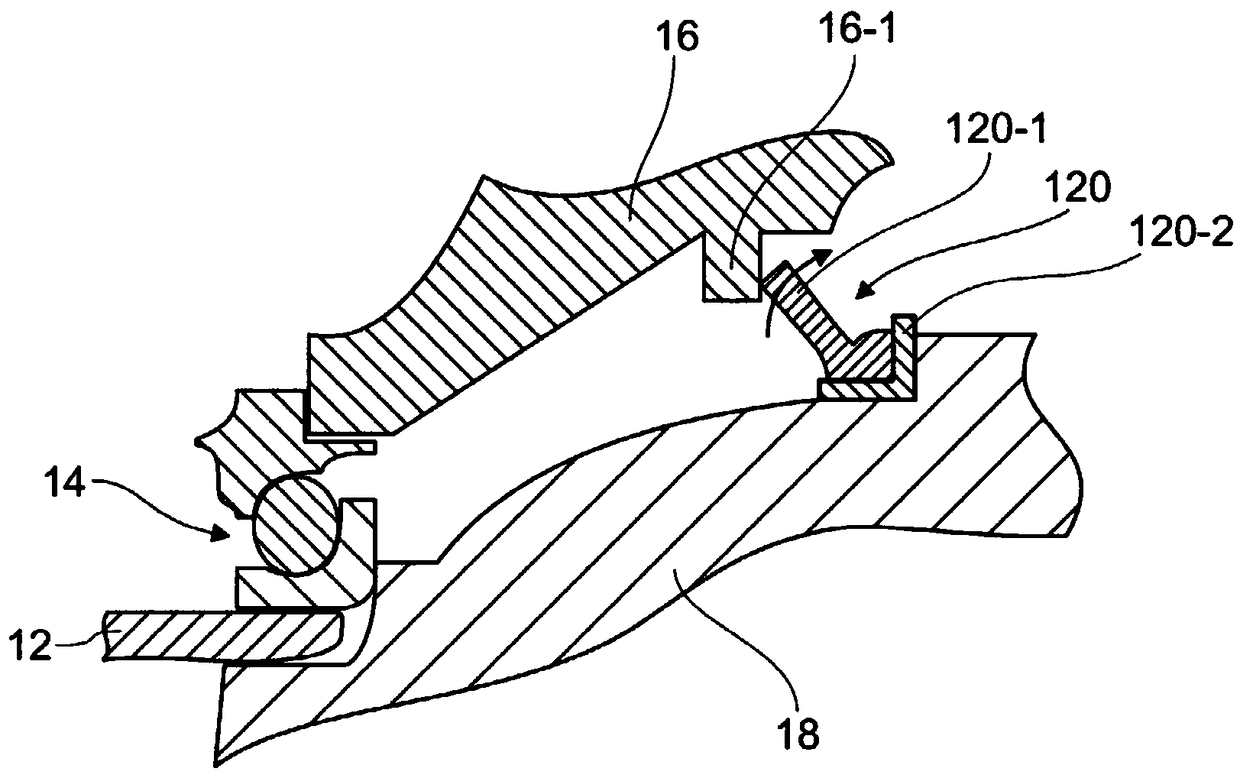

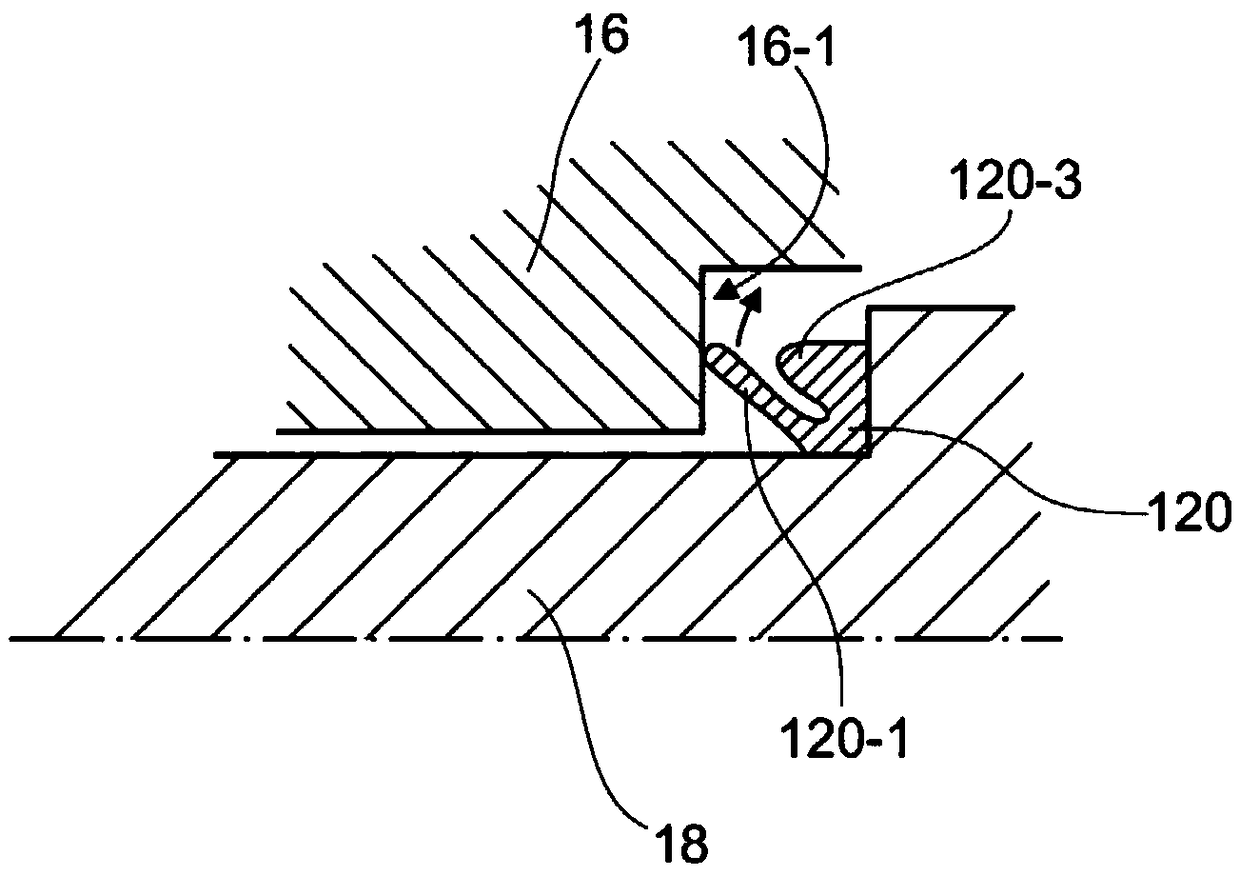

[0029] The sealing device 100 comprises a main seal 110, here designed in the form of a cassette seal, arranged between the bearing device outer ring 14-1 and the bearing device inner ring 14-2, and spaced apart from the main seal 110. A front seal 120 is provided which is arranged between the stationary wheel bearing housing 16 and the rotating cardan shaft 18 .

[0030] like figure 1 It can be further known that the front seal is designed as a centrifugal seal 120 vulcanized on the cardan shaft 18, and the sealing lip 120-1 of the centrifugal seal abuts against the fixed wheel support device housing formed on 16 on the stopper 16-1.

[0031] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com