A multi-screw-conveyer coating stirring machine capable of automatic wall scraping

A mixer and paint technology, applied in mixers, mixers, dissolving and other directions with rotary stirring devices, can solve the problems of single sealing structure, limited effect, limited stirring effect, etc., achieve uniform mixing of paint, and solve the problem of residual paint on the inner wall. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The specific implementation, structure, features and effects provided by the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

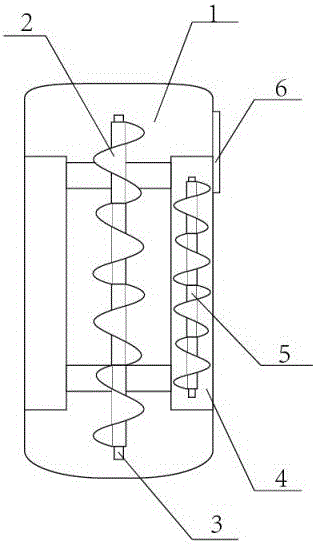

[0011] A self-scraping multi-screw paint mixer, comprising: a mixing tank 1, a stirring device, a wall scraping device, and a control device 6, wherein the mixing tank 1 adopts a barrel-shaped design, and the stirring device is installed inside the mixing tank 1 , the stirring device includes: a rotating rod 3 and an auger 2, the auger 2 is hollow inside, and the hollow position is set on the periphery of the rotating rod 3; a connecting frame is connected to the rotating rod 3, and the wall scraping device passes through The connecting frame is connected with the rotating rod 3; the scraper device includes a scraper 4, a small screw auger 5 is connected to the scraper 4, and the small screw auger 5 is parallel to the scraper 4 Setting; the control device 6 is fixed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com