Ash hopper skirt type aggregate discharge device of vertical roller mill

A vertical mill and ash hopper technology, which is applied in grain processing and other directions, can solve the problem of not being able to meet the functional requirements at the same time, and achieve the effect of being convenient for popularization and application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

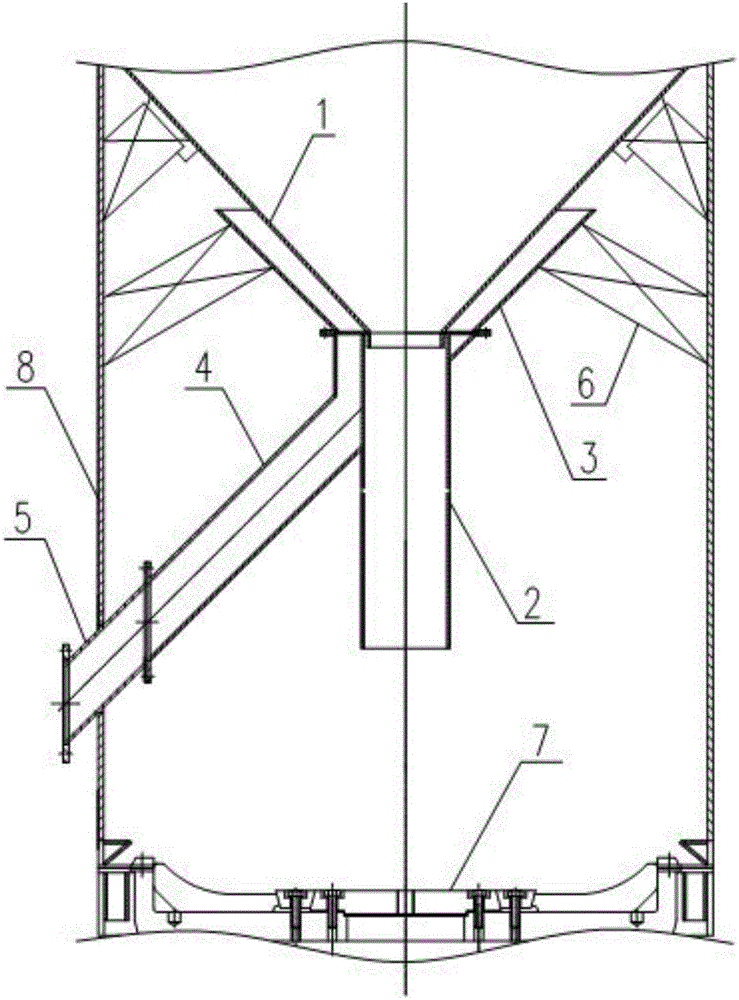

[0018] Such as figure 1 The vertical ash hopper skirt-type collection discharge device shown includes a mill housing 8, an ash hopper 1 for collecting waste materials, a grinding disc 7 for grinding waste materials and guiding the waste materials in the ash hopper The ash hopper discharge pipe 2 on the grinding table is supported by a bracket between the ash hopper 1 and the mill shell 8, and a collection hopper 3 for collecting powder and guiding it out is provided directly below the ash hopper. The ash hopper in the collecting hopper is provided with a hole or a mesh structure for the powder to pass through. The lower end of the collecting hopper is connected to the pipeline 4 , and the lower end of the pipeline is connected to the external discharge pipe 5 . A supporting frame 6 is arranged around the collecting hopper, and one end of the supporting frame 6 is welded on the collecting hopper, and the other end is welded on the shell. The pipeline is connected to the extern...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com