A segmented negative stiffness mechanism and a vibration damping device with the mechanism

A technology of negative stiffness and vibration reduction system, applied in the field of vibration control, can solve the problems of complex structure and few practical applications, and achieve the effect of wide application range, good controllability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

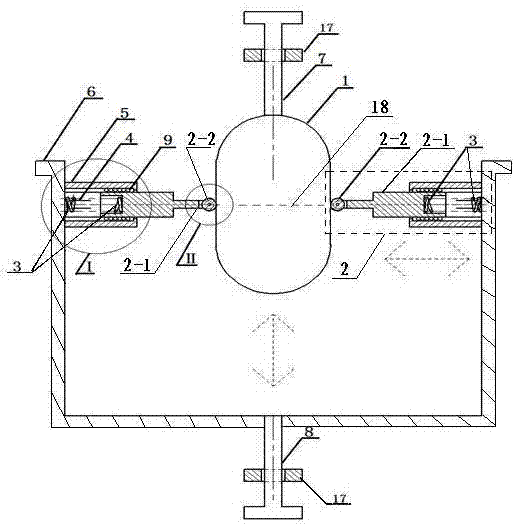

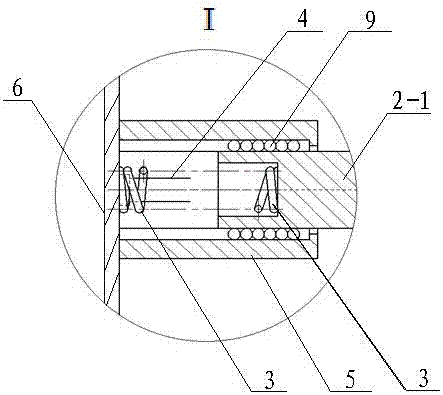

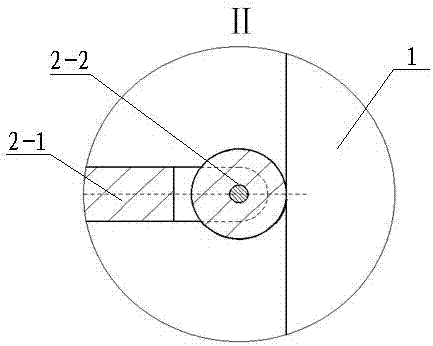

[0028] In order to make the technical scheme of the present invention and main point clearer, below in conjunction with Figure 1-Figure 8 and specific examples to clearly and completely describe the invention.

[0029] Such as Figure 1 ~ Figure 3 As shown, a segmented negative stiffness mechanism based on a roller-moving cam device includes an outer frame 6, a moving cam 1, two identical pre-compressed elastic telescopic push rods 2, and two sets of identical linear bearings 9; The pre-compressed elastic telescopic push rod 2 includes a push rod 2-1, a roller 2-2, a rod sleeve 5, a guide rod 4 and a compression spring 3 with the same pre-compression amount; one end of the pre-compression spring 3, the rod sleeve 5 and the guide rod 4 are all fixed on the inner side of the outer frame 6; the guide rod 4 horizontally supports the pre-compression spring 3, and the guide rod 4 is in contact with the inner side wall of the pre-compression spring 3, and the other part of the pre-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com