Automatic clamshell dustpan

An automatic turning and dustpan technology, applied in cleaning methods, construction, road cleaning, etc., can solve the problems of affecting cleaning efficiency, repetitive labor, and garbage being easily blown away by the wind, so as to improve work efficiency and facilitate control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

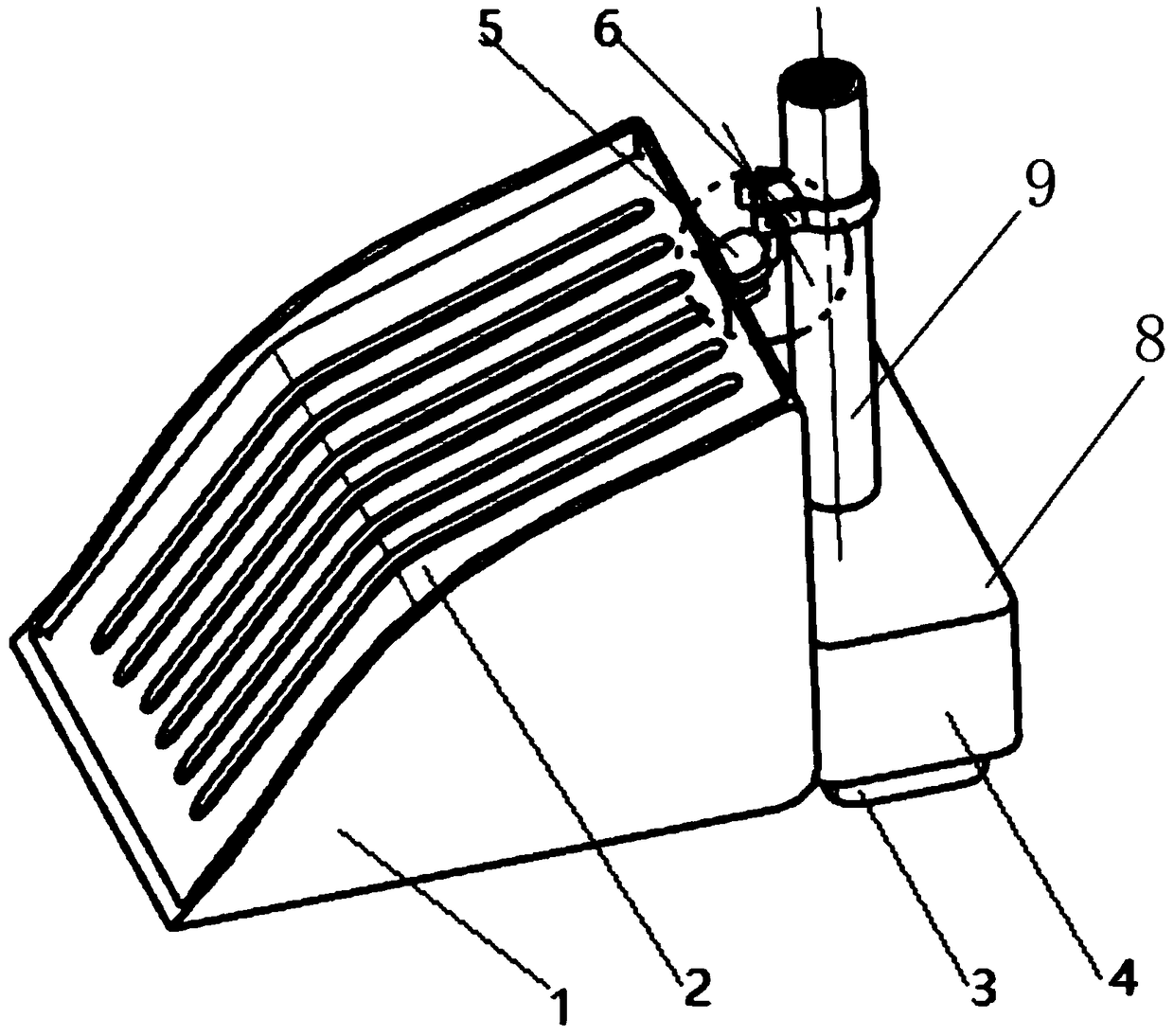

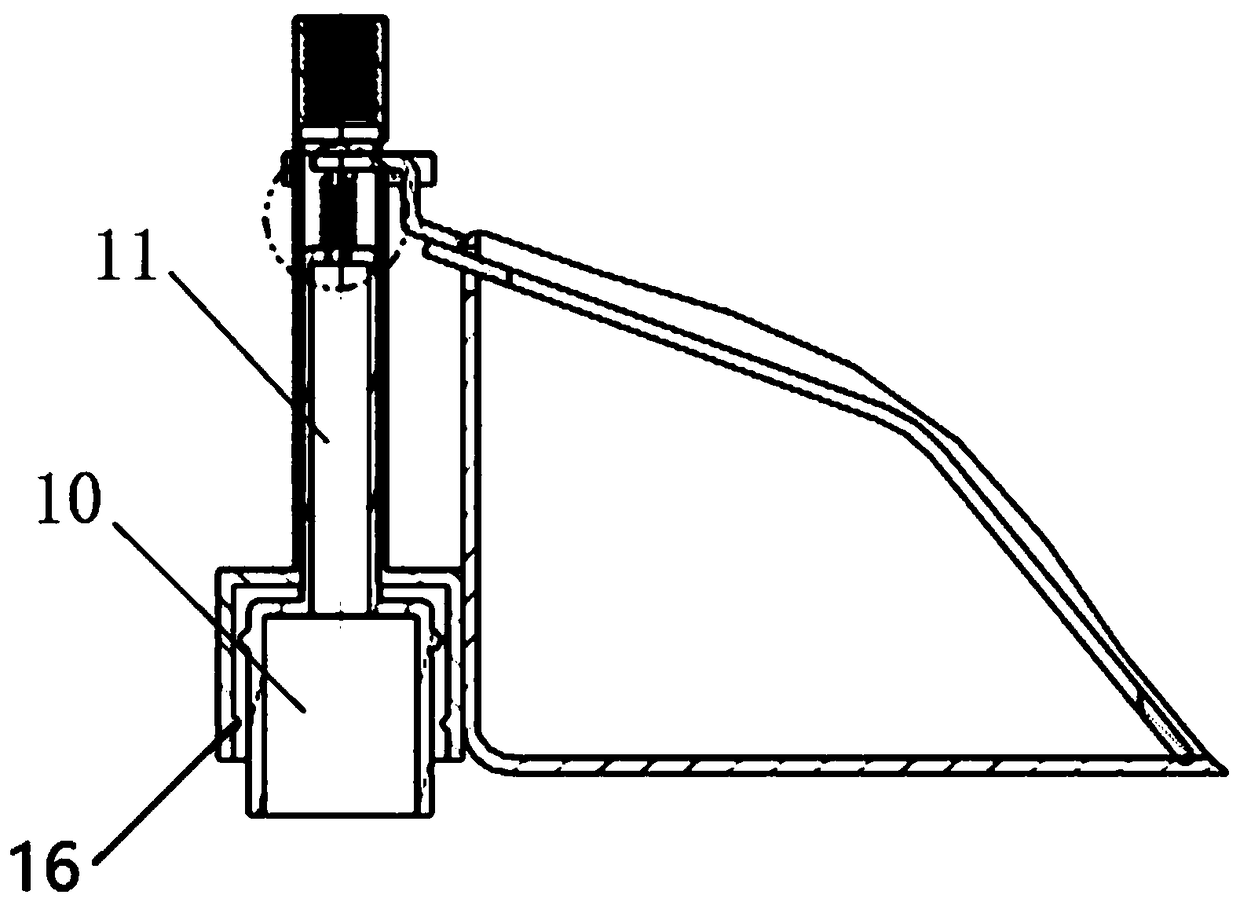

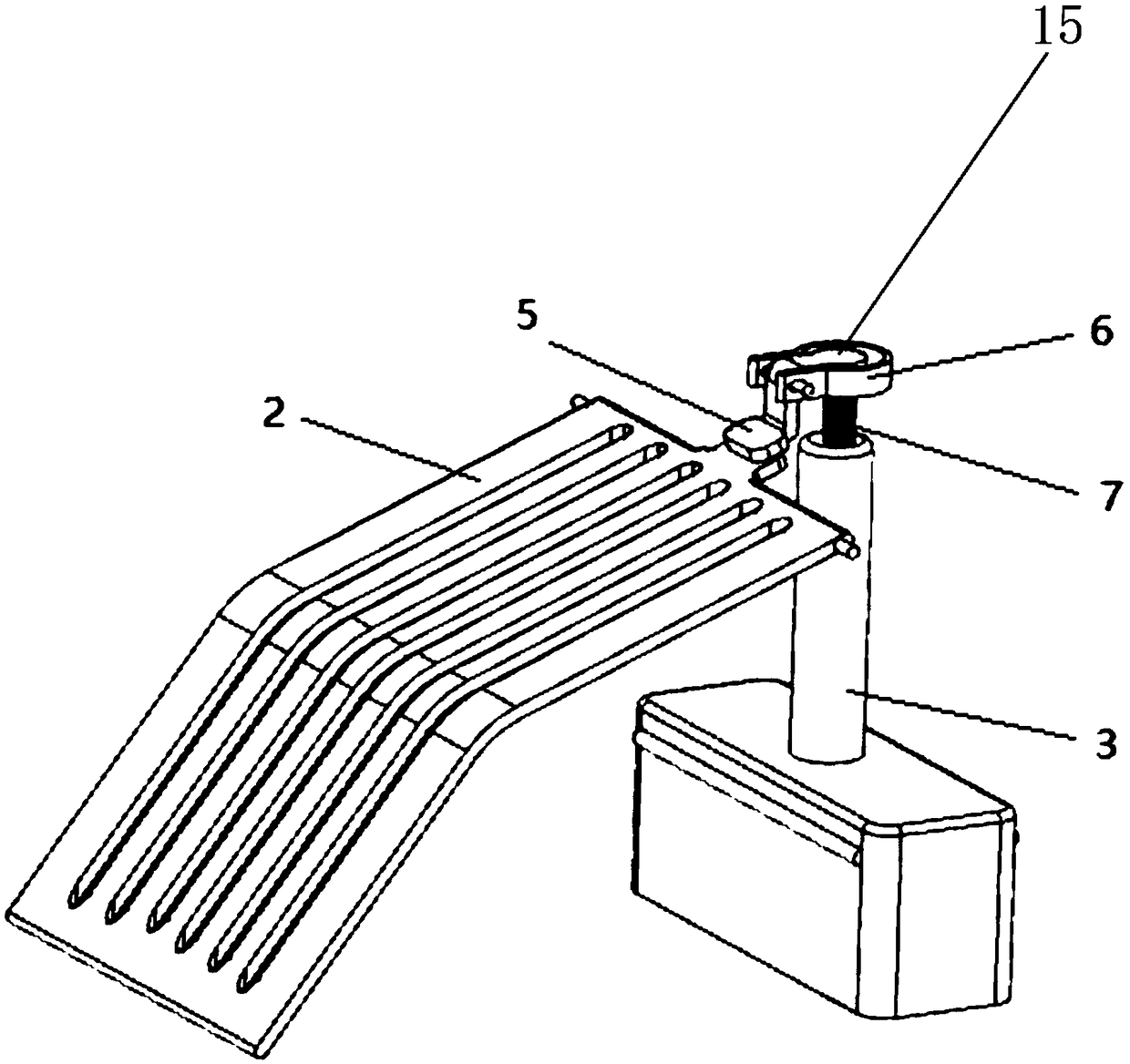

[0020] see figure 1 , figure 2 , image 3 with Figure 4 , the automatic flip-type dustpan according to the present invention includes a dustpan pocket 1 and a baffle plate 2, the baffle plate 2 is installed on the top of the pan pocket 1, and forms a cavity for receiving garbage with the pan pocket 1 ;

[0021] A support 4 is provided on the end surface of one end of the dustpan pocket 1, and the support 4 includes a bottom cavity 8 and a cavity guide post 9 communicated with the bottom cavity 8. Inside the support 4 A moving seat 3 that can move up and down along the support 4 is provided, and the moving seat 3 includes a base 10 located inside the bottom cavity 8, and a transmission rod 11 arranged in the cavity guide post 9. The top of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com