Combined modularization scaffold for large building

A construction and combined technology, applied in the field of scaffolding, can solve the problems of unreliability, low reliability, inconvenient pedal connection, etc., and achieve the effect of ensuring safety and reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

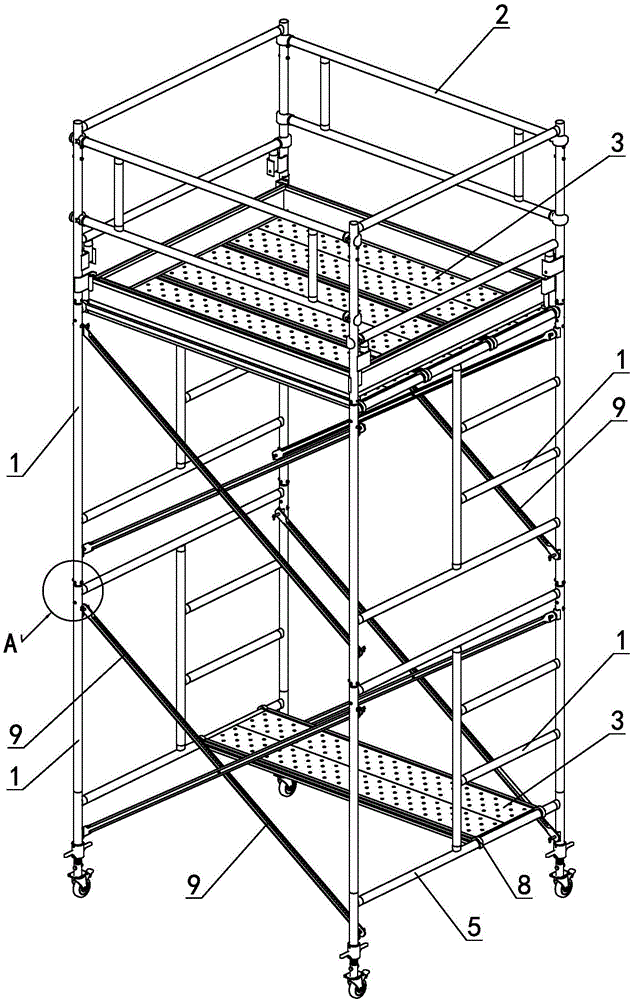

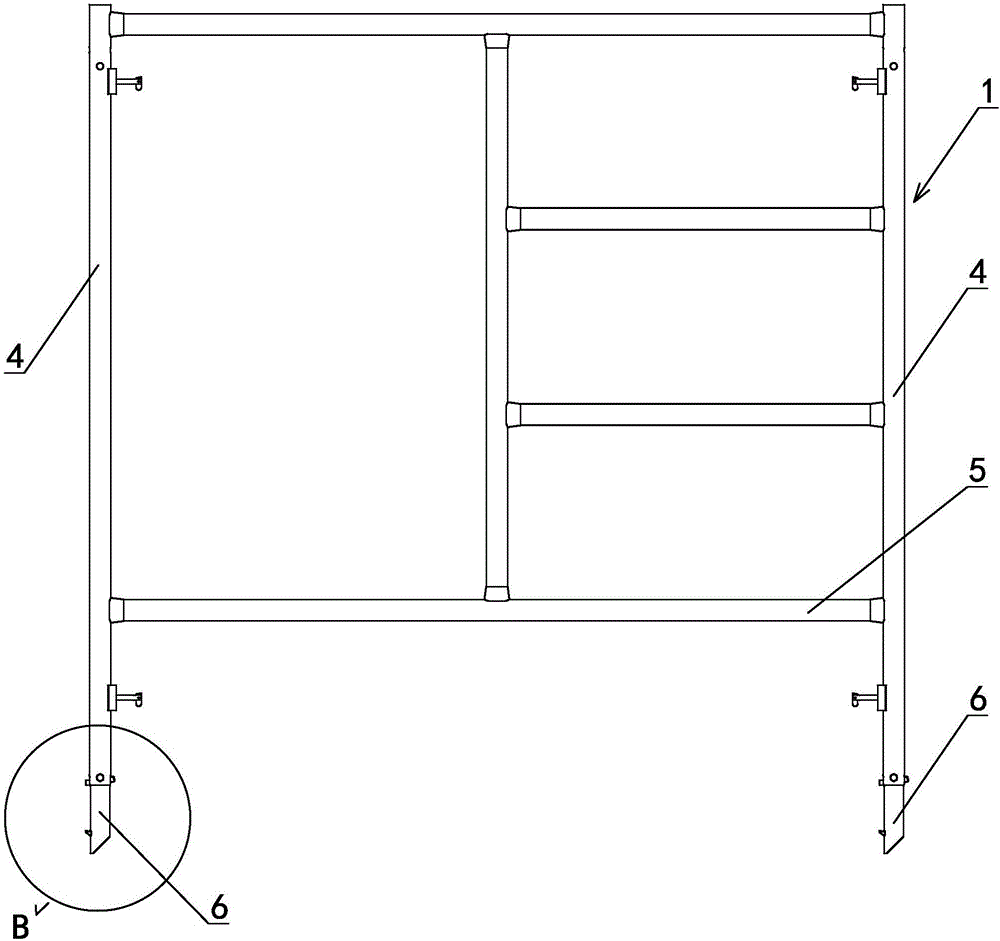

[0031] Example: see attached Figure 1-11 As shown, a combined modular scaffolding for a large building includes a side frame 1, a horizontal guardrail 2 and a pedal 3; the side frame 1 is vertically arranged, and a plurality of side frames 1 are horizontally Arranged in parallel; the horizontal guardrail 2 is detachably connected between two adjacent side frames 1, and the pedal 3 is detachably placed horizontally between two adjacent side frames 1; wherein,

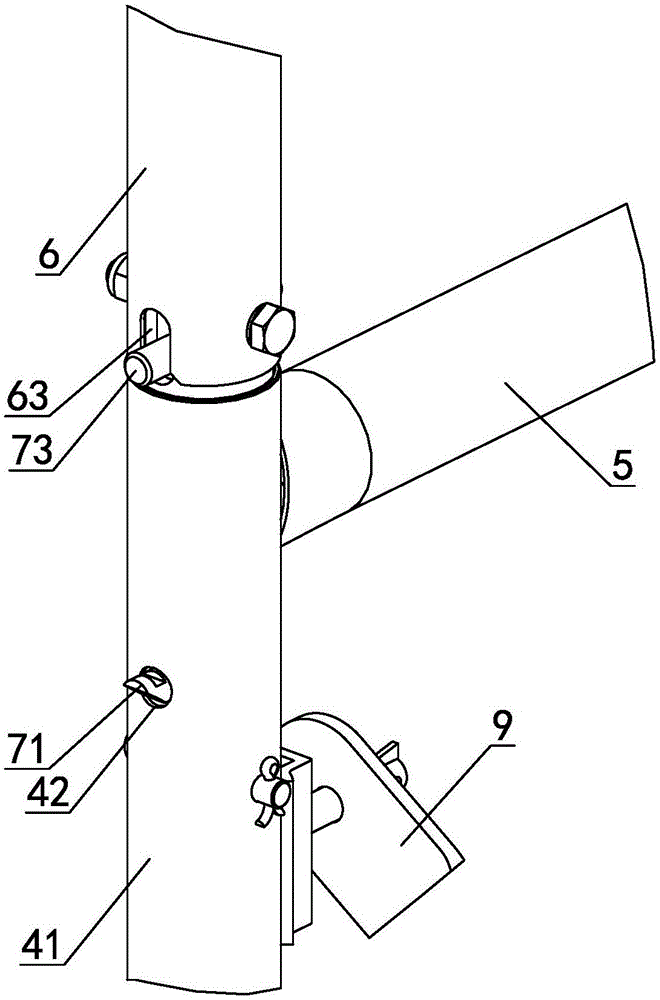

[0032] The side frame body 1 is rectangular and includes two vertical poles 4 arranged in parallel in the horizontal direction, and at least one cross bar 5 connected between the two vertical poles 4; the bottom of the vertical pole 4 is a The plug pin 6 is used for plugging and combining the top of the vertical pole 4 in the side frame body 1 of the lower floor. The bottom of the plug pin 6 is inclined to facilitate the plug-in combination of the side frame body 1 of the upper and lower floors, and The stability after...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com