Forming method for retracting channel of fully mechanized coal mining face device with large dip angle and large mining height

A fully-mechanized mining face and retraction channel technology, which is applied to the formation of a fully-mechanized mining face with a large inclination angle and a large mining height. Problems such as low safety and high labor intensity of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

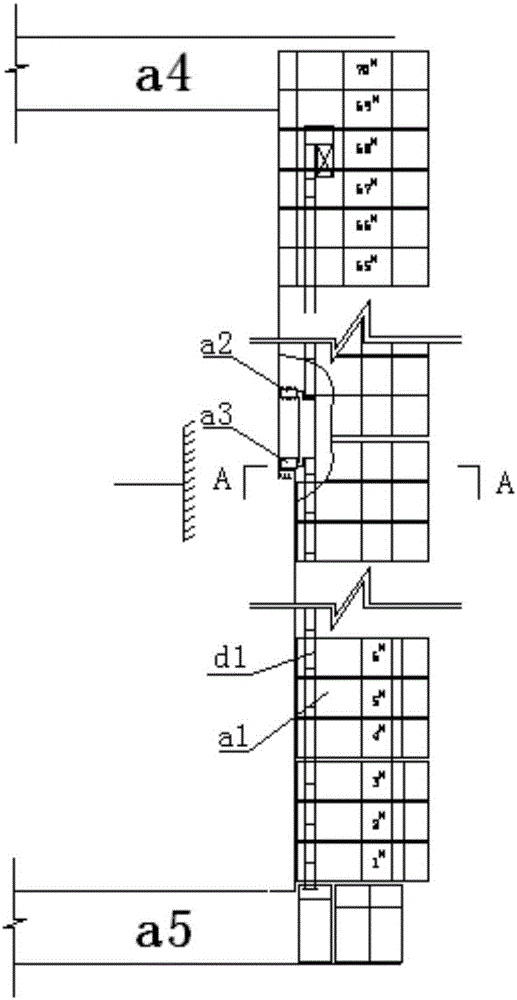

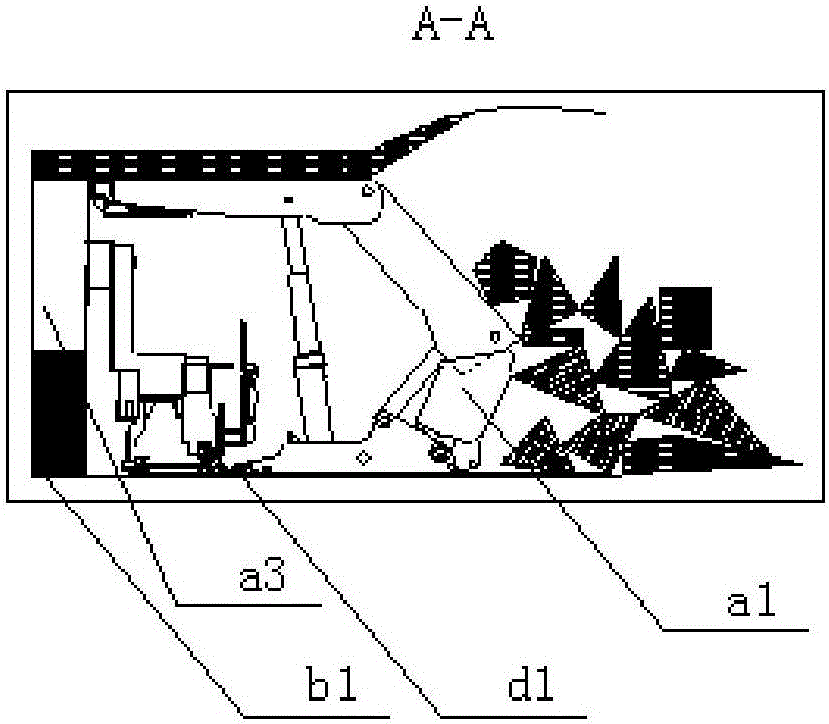

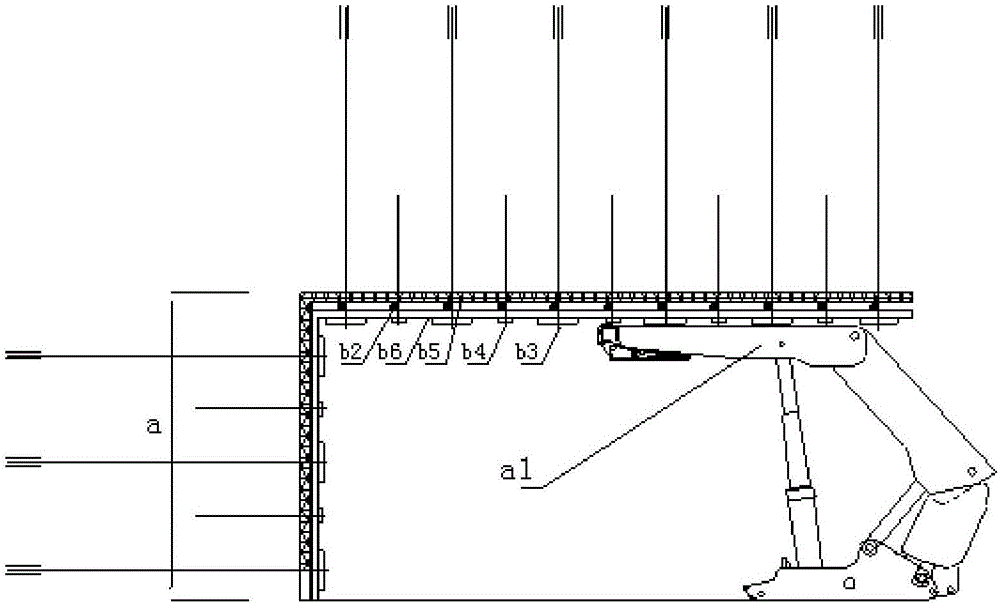

[0027] Such as Figure 1 ~ Figure 3 Shown, the steps of the present invention are:

[0028] S1. When the fully mechanized mining face reaches the stop line, the working face forms a positive inclination; the mining height a of the fully mechanized mining face is preferably controlled at 3.6m to 4.2m

[0029] S2. The upper drum a2 of the shearer and the lower drum a3 of the shearer cut coal along the roof from the lower side of the return airway a4 to the upper side of the transportation lane a5 in order from top to bottom. The working face forms a stepped coal b1. The coal cutting process The hydraulic support a1 is used to follow the roof protection side of the machine; the method adopted in this embodiment is to lag the upper drum a2 of the coal mining machine by about 5m to open the telescopic beam and the side protection of the hydraulic support a1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com