A self-sealing filter module for inkjet printing

一种过滤模块、喷墨打印机的技术,应用在印刷、着墨装置等方向,能够解决印刷标记生产线不理想、过滤器更换费时、连续喷墨打印机不能工作等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

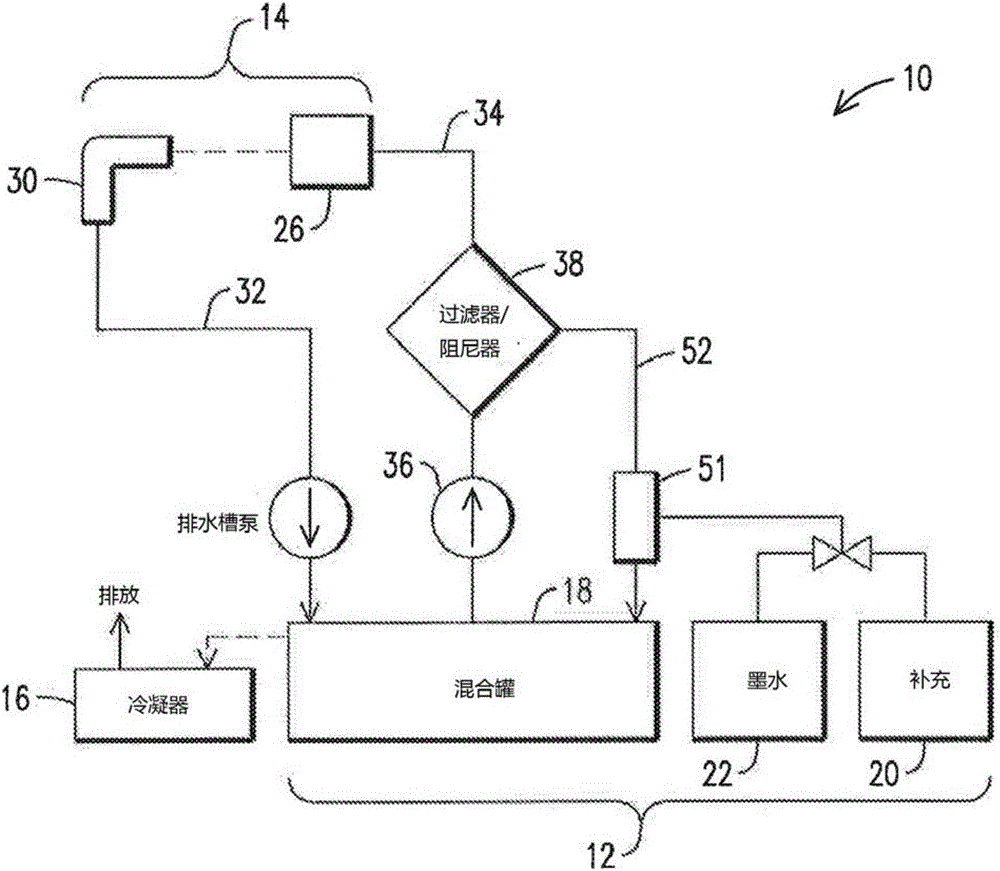

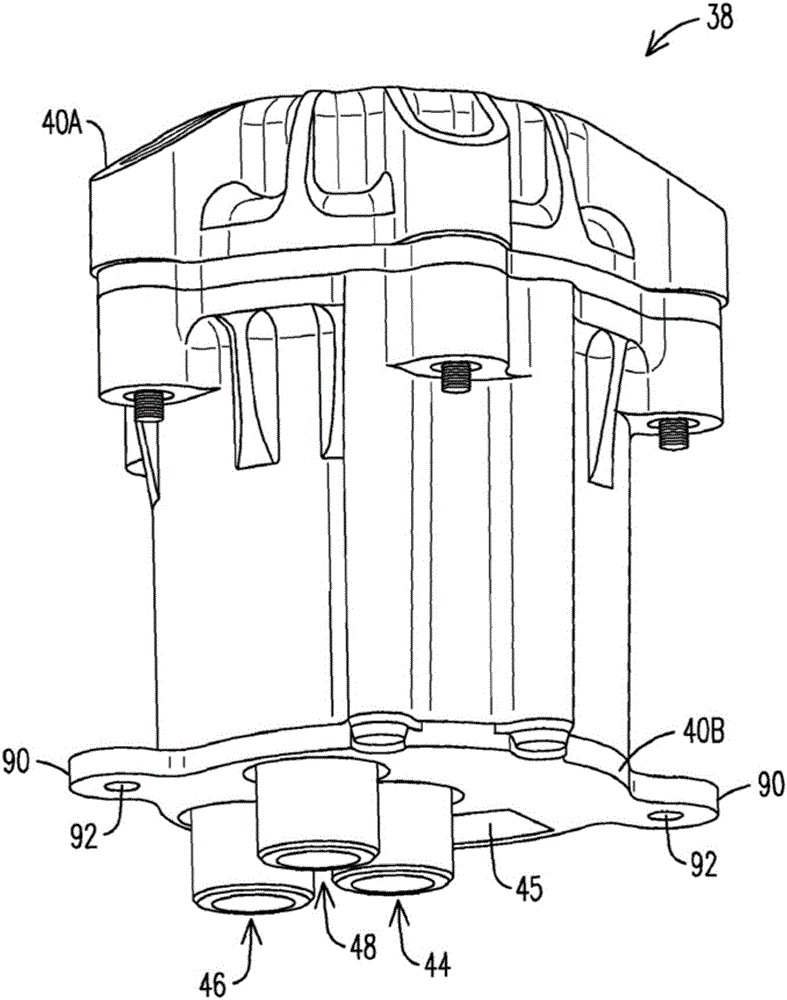

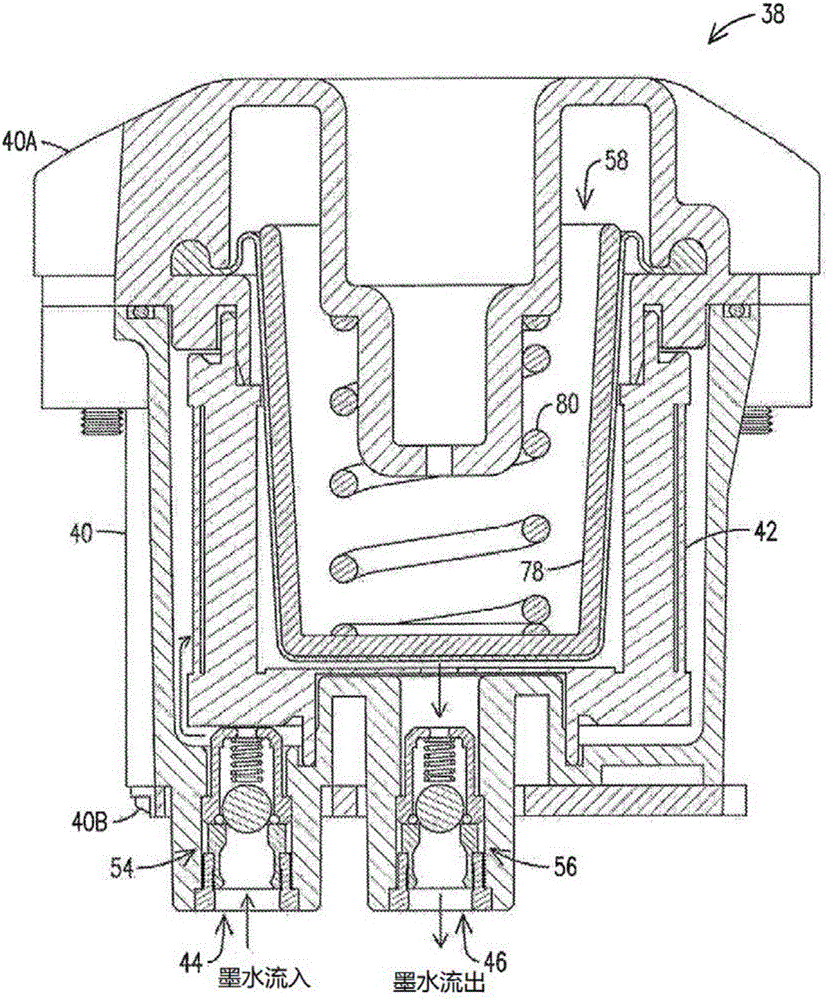

[0017] The inventor has realized that in the process of maintaining the continuous inkjet printer, the filter module to be replaced usually contains a sufficient amount of ink so that the component is regarded as a dangerous product, and some protective measures are required in handling the filter module. The filter module sometimes has a tendency to leak when it is replaced, which can contaminate the work area and printer components. In addition, removing the filter module is usually a rather complicated task, which is time-consuming and troublesome. Therefore, the inventor has developed a "self-sealing" filter module that can minimize or eliminate ink leakage when the continuous inkjet ink flow path is removed. To this end, the filter module is adapted to maximize the evacuating of ink from the filter module when pressure is applied to the ink line and the filter module is removed. Therefore, the filter module according to the embodiment of the present invention can drain th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com