A kind of manufacture method of polyester composition, polyester composition and use thereof

A manufacturing method and composition technology, which are applied in the field of polyester composition manufacturing, can solve the problems of reducing the regeneration speed of cyclic trimers, high intrinsic viscosity of polyester compositions, troublesome operation, etc., and achieve good regeneration inhibition effect, The effect of simple film production process and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

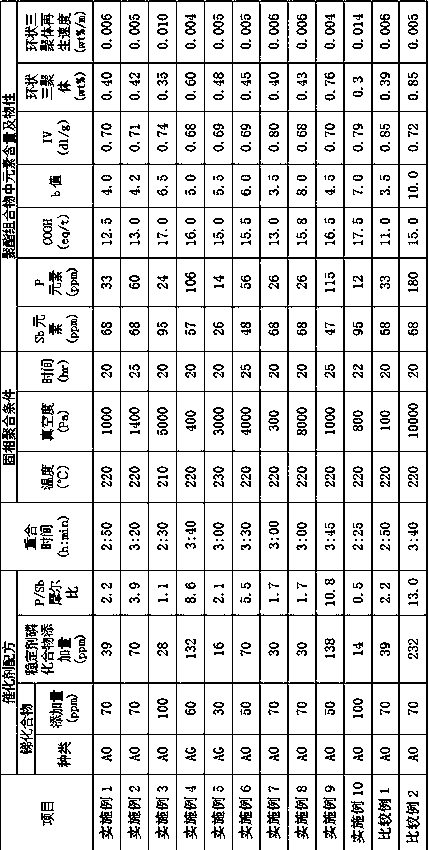

Examples

Embodiment 1

[0051] At a temperature of 250°C, 166 parts by weight of PTA and 71.3 parts by weight of EG were added to the esterification reactor, and the esterification reaction was carried out under normal pressure. When the esterification reaction was completed, the temperature in the esterification reactor was 250°C. Fractional distillation of water yields small molecule polymers.

[0052] In the obtained small molecule polymer, add catalyst AO equivalent to 70 ppm of polyester composition weight in terms of antimony element, magnesium acetate equivalent to 10 ppm of polyester composition weight in terms of alkaline earth metal magnesium element, equivalent to polyester composition in terms of phosphorus element The stabilizer PA with a composition weight of 39ppm starts to decompress and heat up after 5 minutes, and the pressure is decompressed to about 300Pa after 1 hour, and the temperature rises to 290°C after 1.5 hours; when the polycondensation reaction ends, the pressure in the r...

Embodiment 2

[0055] At a temperature of 250°C, 166 parts by weight of PTA and 71.3 parts by weight of EG were added to the esterification reactor, and the esterification reaction was carried out under normal pressure. When the esterification reaction was completed, the temperature in the esterification reactor was 250°C. Fractional distillation of water yields small molecule polymers.

[0056] In the obtained small molecular polymer, add the catalyst AO equivalent to 70ppm of the weight of the polyester composition in terms of antimony, magnesium acetate equivalent to 15ppm of the weight of the polyester composition in terms of alkaline earth metal magnesium, and equivalent to polyester in terms of phosphorus. The stabilizer PEP36 with a composition weight of 70ppm, after 5 minutes, start to decompress and heat up, the pressure is decompressed to about 300Pa after 1 hour, and the temperature rises to 290°C after 1.5 hours; when the polycondensation reaction is over, the pressure in the reac...

Embodiment 3

[0059] At a temperature of 250°C, 166 parts by weight of PTA and 71.3 parts by weight of EG were added to the esterification reactor, and the esterification reaction was carried out under normal pressure. When the esterification reaction was completed, the temperature in the esterification reactor was 250°C. Fractional distillation of water yields small molecule polymers.

[0060] In the obtained small molecular polymer, add the catalyst AO equivalent to 100ppm of the weight of the polyester composition in terms of antimony, the magnesium acetate equivalent to 15ppm of the weight of the polyester composition in terms of alkaline earth metal magnesium, and the equivalent of polyester in terms of phosphorus. Composition weight 28ppm stabilizer PA, after 5 minutes, start to decompress and heat up, the pressure is decompressed to about 300Pa after 1 hour, and the temperature rises to 290°C after 1.5 hours; when the polycondensation reaction ends, the pressure in the reactor is abou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com