A kind of polyester composition and its preparation method and application

A composition and polyester technology, applied in the field of polyester composition and preparation thereof, can solve the problems of insignificant regeneration inhibition effect of oligomer cyclic trimer, troublesome operation, reduction of content and the like, and achieve good regeneration inhibition effect , The effect of low processing cost and industrial simplicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

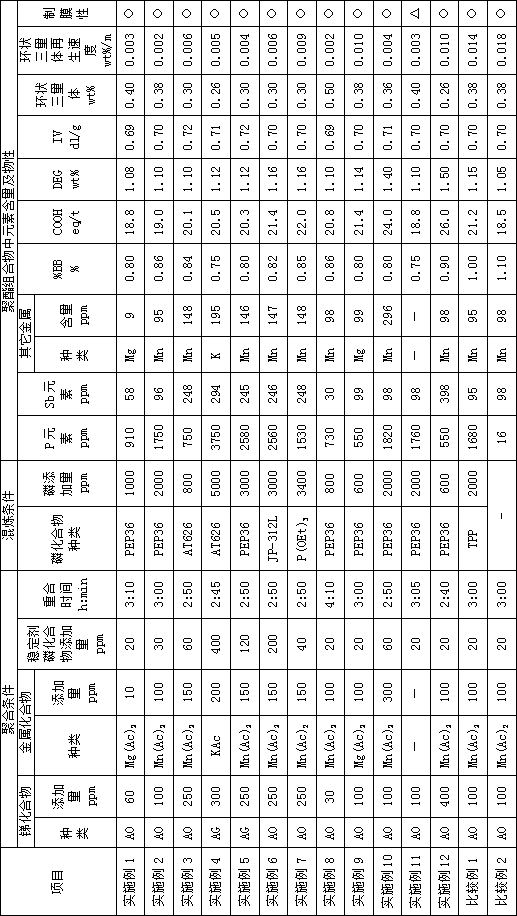

Examples

preparation example Construction

[0034] The invention also discloses a preparation method of the polyester composition, which includes esterification reaction or transesterification reaction, polymerization reaction, solid phase polymerization reaction and mixing reaction. This preparation method comprises the steps:

[0035] (1) Reaction of aromatic dicarboxylic acid or its esterified derivatives with aliphatic dihydric alcohol to obtain small molecular polymer, and then polycondensation reaction of small molecular polymer to obtain polyester, adding phosphorus element in the polycondensation reaction stage A stabilizer phosphorus compound of 10 to 400 ppm relative to the weight of polyester chips, and an antimony compound of 32 to 420 ppm relative to the weight of polyester chips in terms of antimony elements; and then solid-phase polymerization of the obtained polyester to obtain polyester chips;

[0036] (2) Add the polyester chip and trivalent phosphorus compound in step (1) into a two-shaft mixer to mel...

specific Embodiment approach

[0060] The advantages of the present invention will be described in detail below from the enumerated examples and comparative examples. The present invention is not limited to the following examples.

[0061] Some compounds involved in the examples are as follows:

[0062] (1) Terephthalic acid (PTA): the grade is high purity, Yangzi Petrochemical;

[0063] (2) Ethylene glycol (EG): BASF company;

[0064] (3) Antimony trioxide (AO): Nippon Seiko Co., Ltd.;

[0065] (4) Antimony glycol (AG): Yangzhou Yangtai Chemical Co., Ltd.;

[0066] (5) Phosphoric acid (PA): Shanghai Haohua Chemical Co., Ltd.;

[0067] (6) Bis(2,4-di-tert-butylphenyl) pentaerythritol diphosphite (PEP36): Asahi Denka;

[0068] (7) Bis(2.4-di-tert-butylphenyl) pentaerythritol diphosphite (AT626): Jinhai Yabao;

[0069] (8) Triphenyl phosphate (TPP): Aladdin's reagent

[0070] (9) Phosphite triacetate [P(OEt) 3 ]: Aladdin Reagent

[0071] (10) Phosphite Trilaurate (JP-312L): Chengbei Reagent

Embodiment 1

[0073] Step (1) At a temperature of 250°C, 166 parts by weight of PTA and 71.3 parts by weight of EG are added to the esterification reactor, and the esterification reaction is carried out under normal pressure. When the esterification reaction is completed, the temperature in the esterification reactor At 250°C, water is distilled off to obtain small molecule polymers.

[0074] In the obtained small molecule polymer, add catalyst AO equivalent to 60 ppm of polyester composition weight in terms of antimony element, magnesium acetate equivalent to 10 ppm of polyester composition weight in terms of alkaline earth metal magnesium element, equivalent to polyester composition in terms of phosphorus element Composition weight 20ppm stabilizer PA, after 5 minutes, start to depressurize and heat up, the pressure decompresses to about 300Pa after 1 hour, and the temperature rises to 290°C after 1.5 hours; when the polycondensation reaction ends, the pressure in the reactor is about 200P...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com