Secondary edge rolling and positioning device for steel strips

A circular positioning and steel strip technology, applied in the field of steel strip production and processing, can solve the problems of cumbersome operation and low processing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

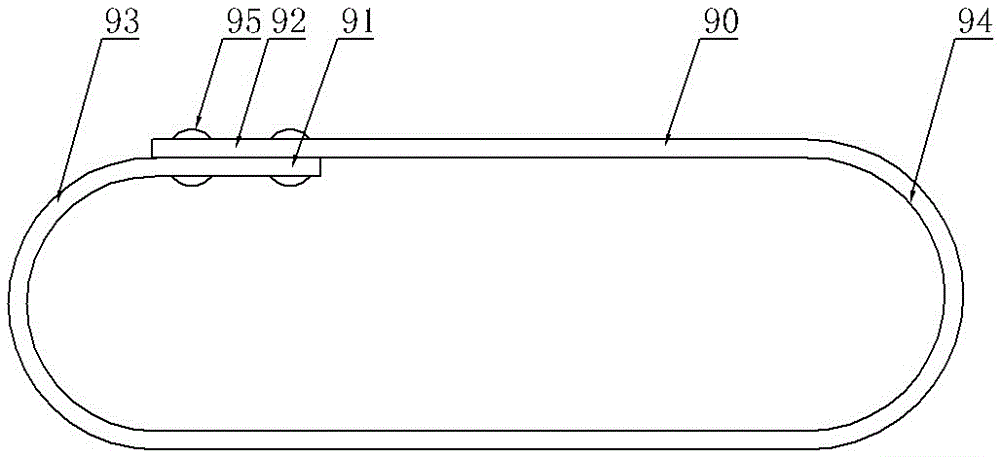

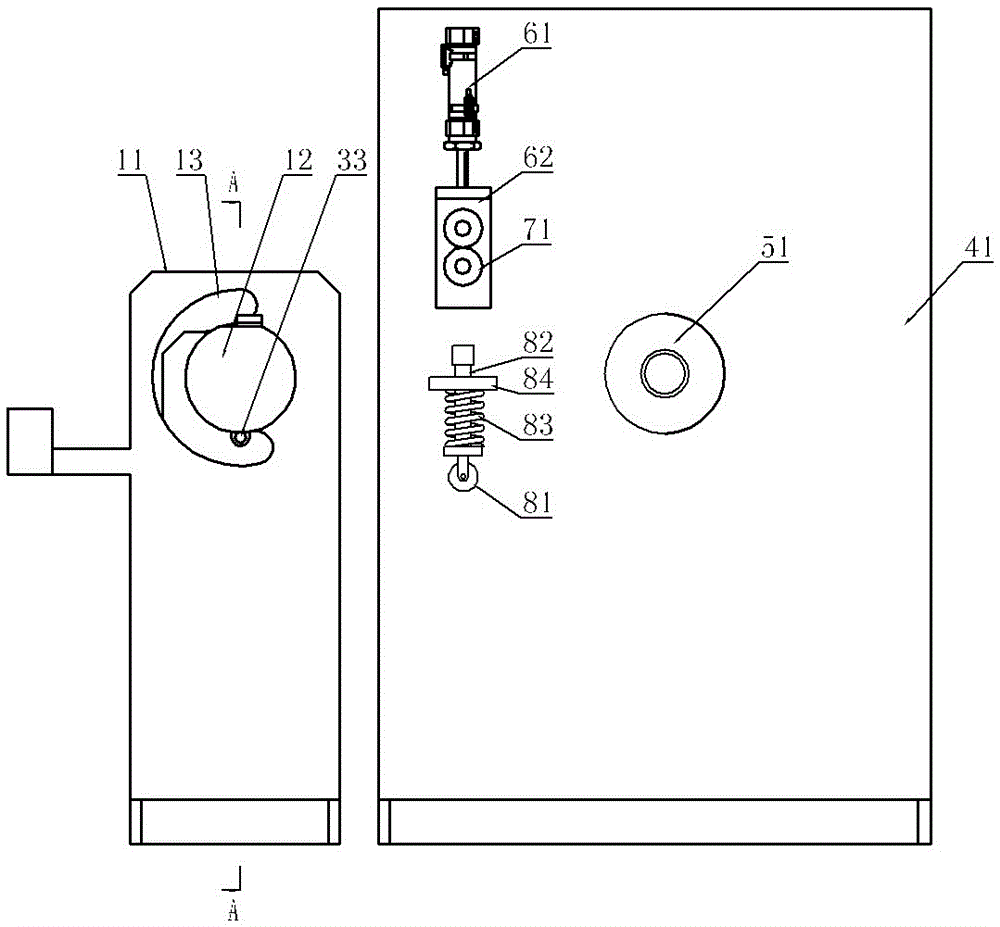

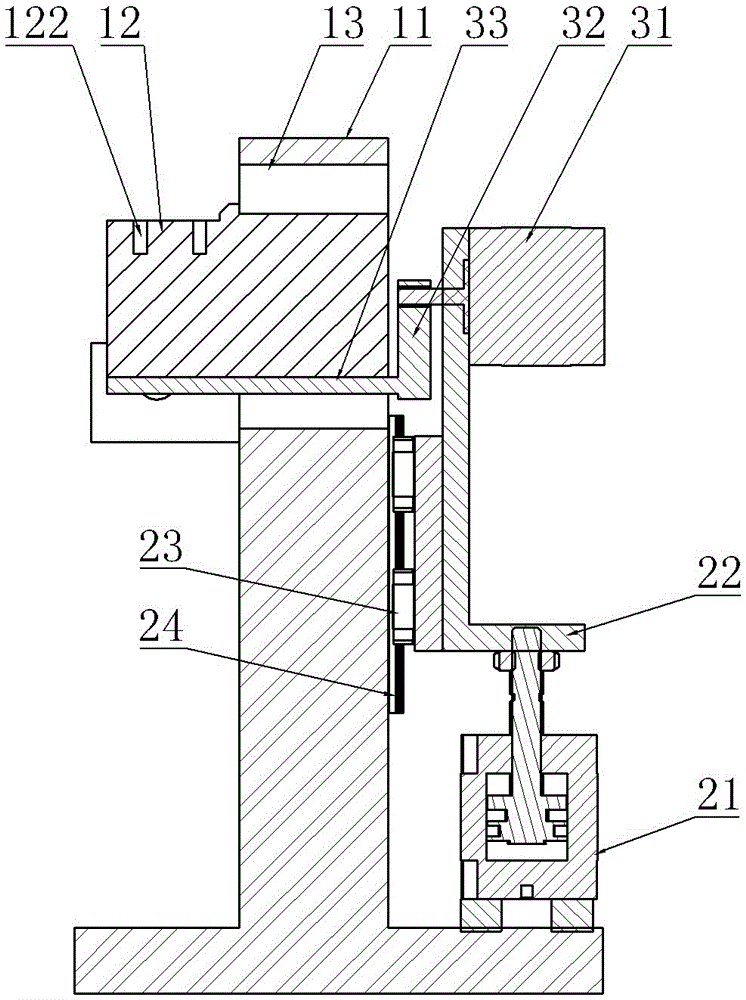

[0018] Such as Figure 2~Figure 4 As shown, it includes a first support frame 11 and a second support frame 41, the first support frame 11 is provided with a simulation block 12 and a rolling mechanism, and the second support frame is provided with a support roller 51, a steel belt tensioning mechanism, The steel belt lifting mechanism and the steel belt pressing mechanism, the supporting roller and the simulation block are located on the same horizontal plane, the steel belt tensioning mechanism, the steel belt lifting mechanism and the steel belt pressing mechanism are located between the simulation block and the supporting roller;

[0019] The simulation block 12 is vertically fixed on the first support frame 11, and the side surface perpendicular to the first support frame 11 of the simulation block 12 is composed of an arc-shaped curved surface 123 and a first plane 121 connecting the top two ends of the arc-shaped curved surface. The first support frame 11 The part locat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com