Fast dual-probe atomic force microscope approximation device and fast dual-probe atomic force microscope approximation method

An atomic force microscope and dual-probe technology, applied in scanning probe microscopy, measuring devices, scanning probe technology, etc., can solve time-consuming and labor-intensive problems, simplify steps, save time and effort in operation, and speed up the approach adjustment process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

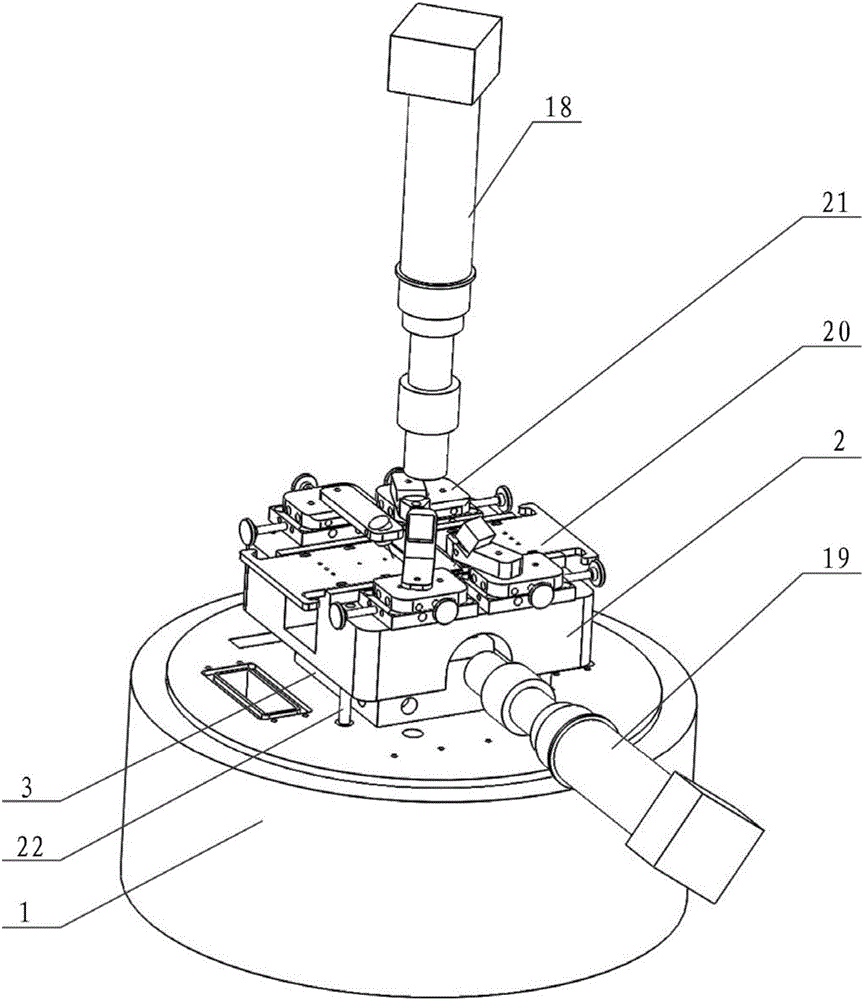

[0038] Such as Figure 3-5 As shown, a double-probe atomic force microscope rapid approach device includes a microscope base 1, a detection head base 2 is arranged on the microscope base 1, the detection head base 2 is connected to the microscope base 1 through a lifting assembly, and the microscope base 1 is connected to the detection A sample scanning platform 3 is provided between the head bases 2, a sample table 4 for placing samples is provided on the sample scanning platform 3, and a master probe assembly and a slave probe assembly are provided on the detection head base 2;

[0039]The main probe assembly includes a main probe 5, the main probe 5 is connected with a first cantilever beam 6, a first laser 7 and a first photoelectric receiver 8 are arranged above the first cantilever beam 6, and the first cantilever beam 6 is connected with an XY Axis micrometer positioning stage 9;

[0040] The slave probe assembly includes a slave probe 10, which is connected with a sec...

Embodiment 2

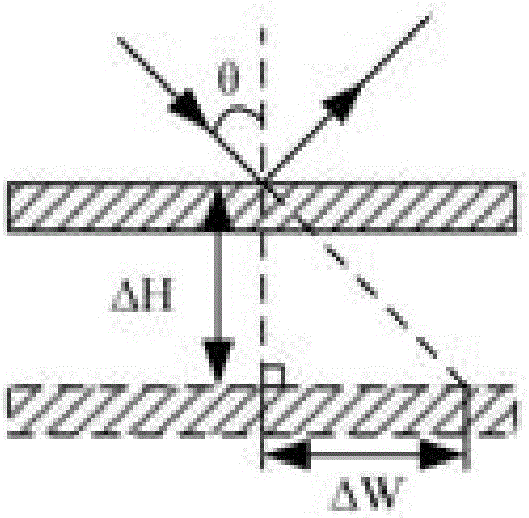

[0055] The incident light and reflected light on the first cantilever beam 6 form a plane P1, the incident light and reflected light on the second cantilever beam 11 form a plane P2, and the plane P1 and the plane P2 overlap each other. In general, the plane P1 and the plane P2 are intersecting each other, such as the two sides are perpendicular to each other. In this state, the corresponding lasers and photoelectric receivers and other components are scattered and occupy a large space, which leads to a large space occupied by the equipment as a whole. . Therefore, in order to save space to the greatest extent, the plane P1 and the plane P2 are arranged to overlap each other, that is, the two sides are parallel to each other and superimposed to achieve a superimposed state, and then the components such as the laser and the photoelectric receiver are no longer scattered, and the positions are more compact. It takes up less space.

Embodiment 3

[0057] Such as Figure 6 As shown, a two-probe AFM fast approximation method, including the following steps:

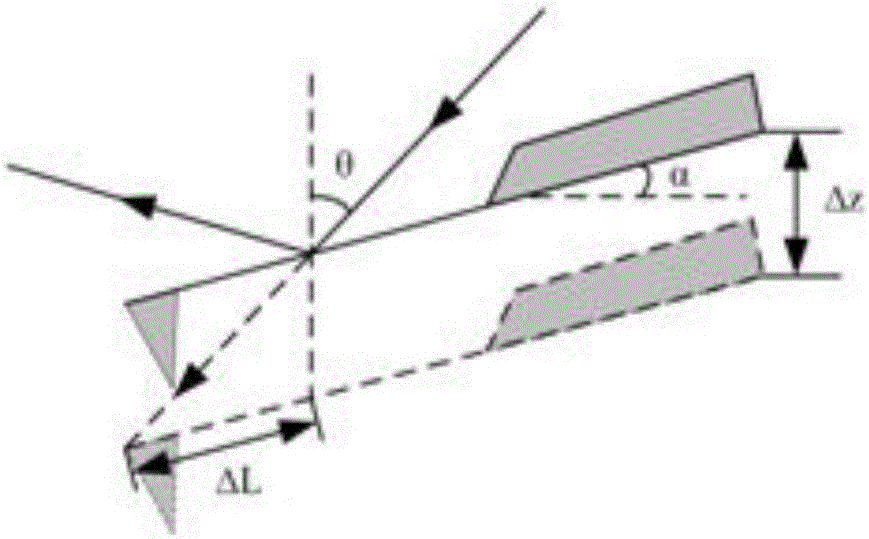

[0058] a. The main probe 5 is adjusted in the horizontal X-axis and Y-axis direction, so that the main probe 5 is close to the slave probe 10, and the slave probe 10 is adjusted along the vertical Z-axis direction, so that the slave probe 10 is lower than the master probe 5 ;

[0059] b. Adjust the lasers of the main probe 5 and the slave probe 10 respectively, so that the incident light spot of the laser is located at the midpoint of the front end of the cantilever beam of the main probe 5 and the cantilever beam of the slave probe 10, and the reflected light spot is located at the cross of the photoelectric receiver point, wherein the light emitted from the laser of the probe 10 is reflected by the mirror 13, and the spot of the light is shot vertically on the cantilever beam from the probe 10;

[0060] c. Move the main probe 5, the slave probe 10, the laser and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com