Inkjet printing system and deviation correction method for inkjet printing system

An inkjet printing and printing nozzle technology, applied in printing devices, printing, transfer materials, etc., can solve the problems of time-consuming and labor-intensive mechanical equipment, inkjet images shifting to the original position, and printing quality degradation, etc., to achieve fast and accurate operation, Ensure the printing quality and the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The inkjet printing system and the deviation correcting method for the inkjet printing system in the present invention will be described in detail below in conjunction with the embodiments and the accompanying drawings.

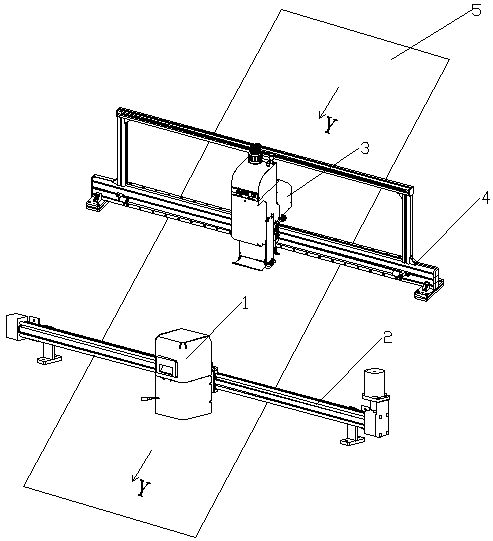

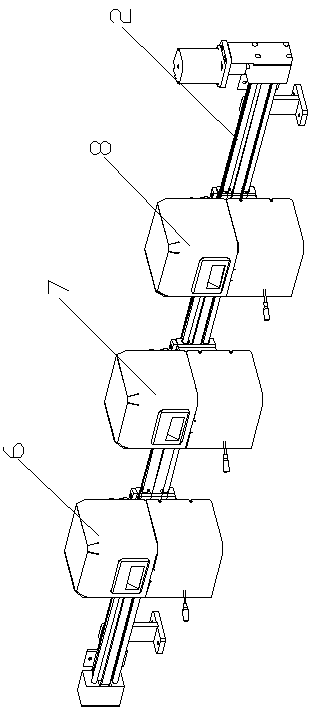

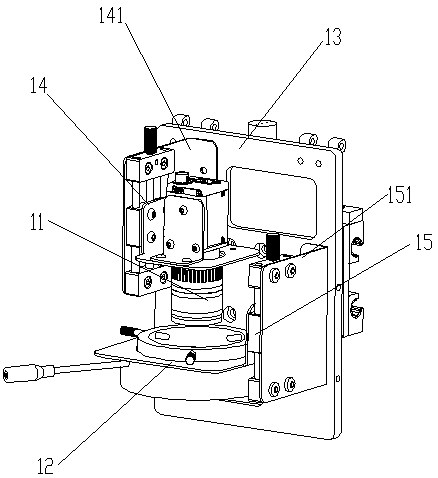

[0044] Such as figure 1As shown, the present invention exemplifies an embodiment of an inkjet printing system. The inkjet printing system is installed above the printing medium 5, and the printing medium 5 is rapidly fed and transported at one time. The inkjet printing system includes a printing unit, a monitoring module and deviation correction software. The printing unit includes a printing module 3 and a printing module beam 4. The monitoring module includes a photographing device 1 and a support beam 2, wherein the printing module beam 4 spans above the printing medium 5, The printing module 3 is installed on the printing module beam 4, and the printing nozzle (not shown in the figure) is installed under the printing module 3. The total width of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com