A fully automatic roll forming production line

A roll forming, production line technology, applied in the stacking of objects, metal processing, manufacturing tools, etc., can solve the problems of inability to achieve synchronous online processing, pause, slow speed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described below in conjunction with the examples, but the protection scope of the present invention is not limited only to the examples.

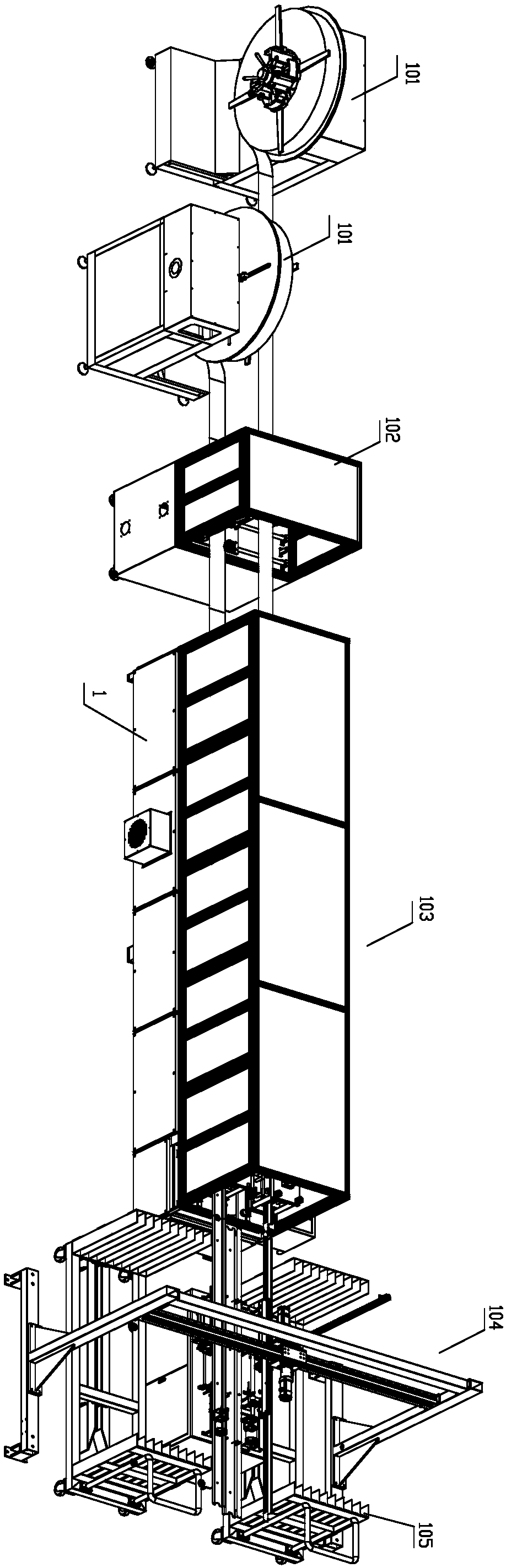

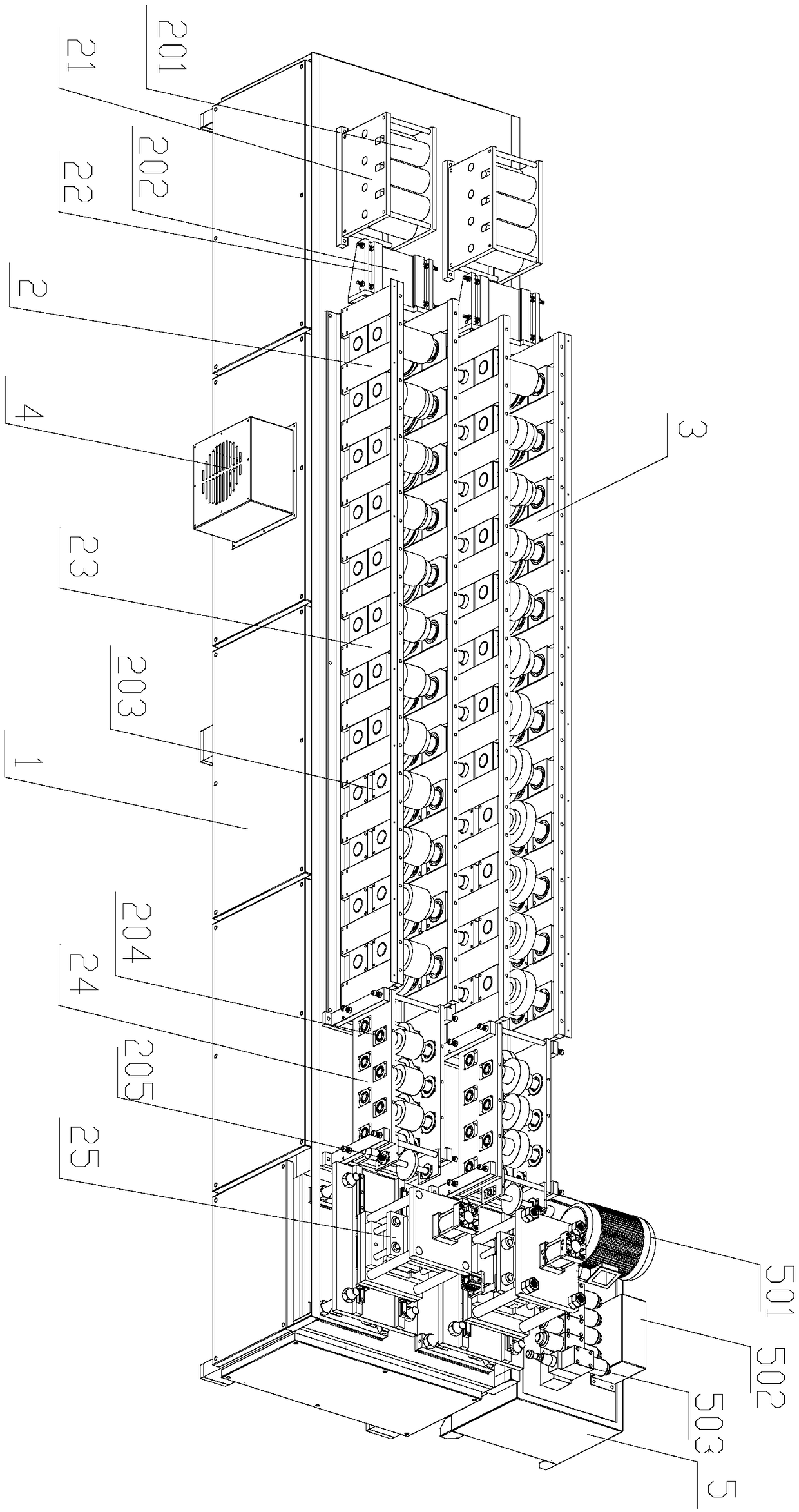

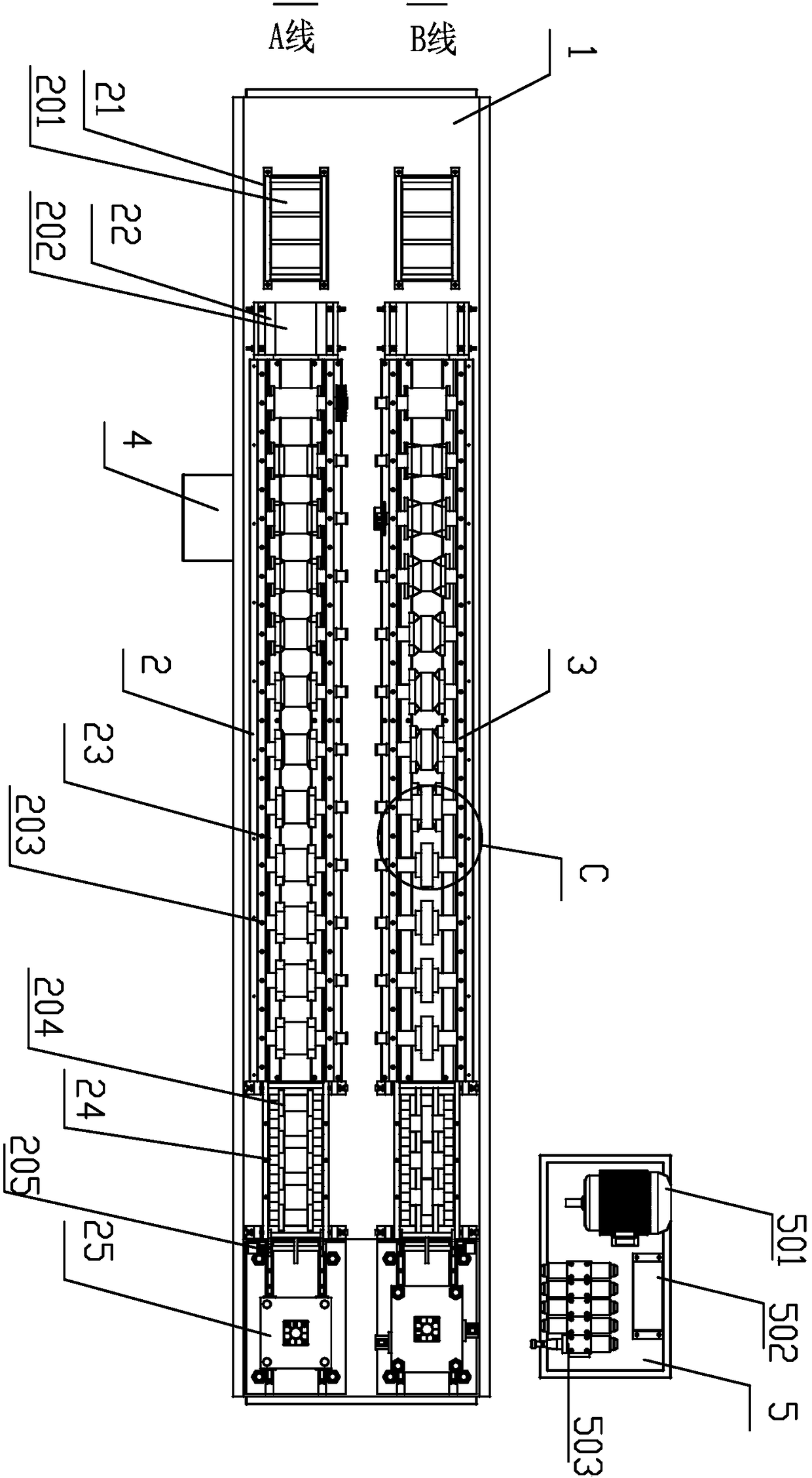

[0049] combine figure 1 As shown, a fully automatic roll forming production line, according to the production process, includes:

[0050] Material rack 101: used for winding the raw material coil; the coil material on the material rack rotates with the material rack, and the metal plate moves forward, continuously feeding the material into the roll forming part.

[0051] Automatic welding machine 102: used to butt weld the new roll of material and the unused material of the previous roll when one roll of material is used up and another roll of material needs to be replaced; in order to continue production, the automatic welding machine This can be done.

[0052] Roll forming machine 103: used to roll the raw material coil into a desired shape;

[0053]Automatic palletizer 104: the turning mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com