A mobile platform for a ship-borne maintenance management system

A technology of management system and mobile platform, which is applied in the field of mobile platform of ship-borne tank maintenance management system, to achieve high safety and reliability requirements, improve carrying capacity, and solve the effect of rolling/pitching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

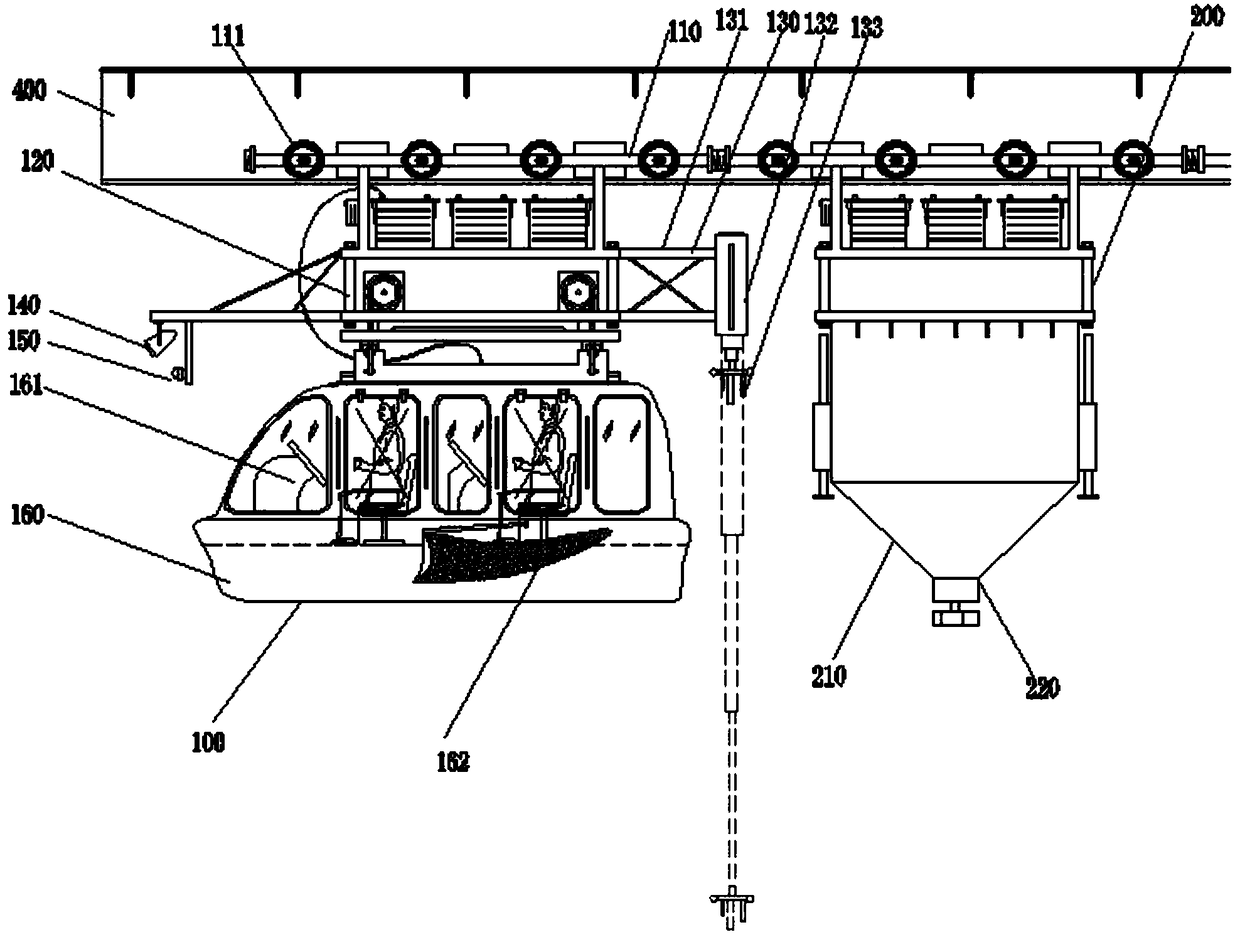

[0034] Such as figure 1 , Figure 5 and Figure 8As shown, a mobile platform of a ship-borne cabin breeding management system includes a centralized control module 100 hoisted on the top track 400 of the breeding cabin and a feeding module 200; the centralized control module 100 includes a controller, The positioning sensor 180, the first suspension bracket 120, the hull 160 and the first driving module 110 hoisted on the rail 400, the first suspension bracket 120 is installed below the first driving module 110, the hull 160 is connected to the first suspension bracket 120, the two ends of the first suspension bracket 120 are respectively provided with a water quality monitoring module 130 and a video monitoring module 140, the water quality monitoring module 130 includes a water quality monitoring probe 133 and is installed on the first suspension A fixed bracket 131 at one end of the bracket 120, a downward telescopic bracket 132 is installed on the fixed bracket 131, and ...

Embodiment 2

[0037] This embodiment is on the basis of embodiment 1:

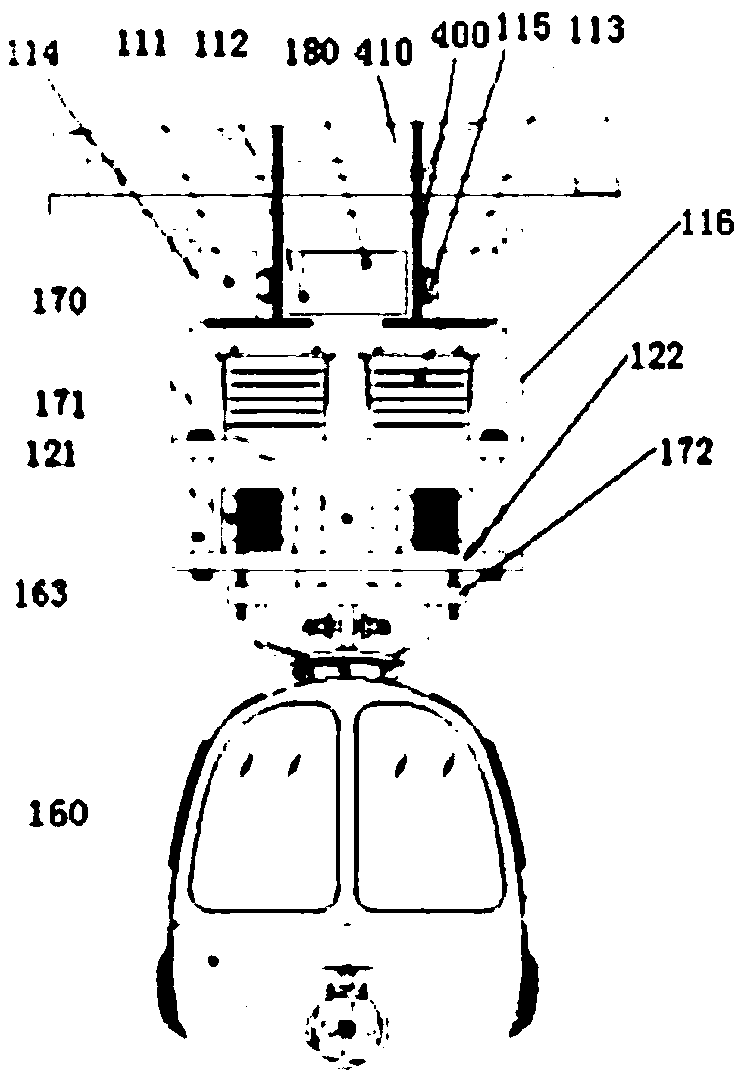

[0038] Such as figure 2 and image 3 As shown, the centralized control module 100 also includes a lifting module 170 connected to the first suspension bracket 120, the lifting module 170 is connected to the controller, and the hull 160 is detachably installed on the lifting module 170, the hull 160 is connected to the power storage module 113 on the first driving module 110 through a cable 164. The feeding port and the personnel operating platform 161 connected to the controller are arranged in the hull 160. The two sides of the hull 160 are provided with Extensible fishing net 162.

[0039] When executing the automatic operation process, there may or may not be managers on the centralized control module 100. When there are managers, the managers can stop the automatic program at any time through the personnel operation platform 161 and perform necessary manual management operations, such as emergency To stop runnin...

Embodiment 3

[0041] This embodiment is on the basis of embodiment 2:

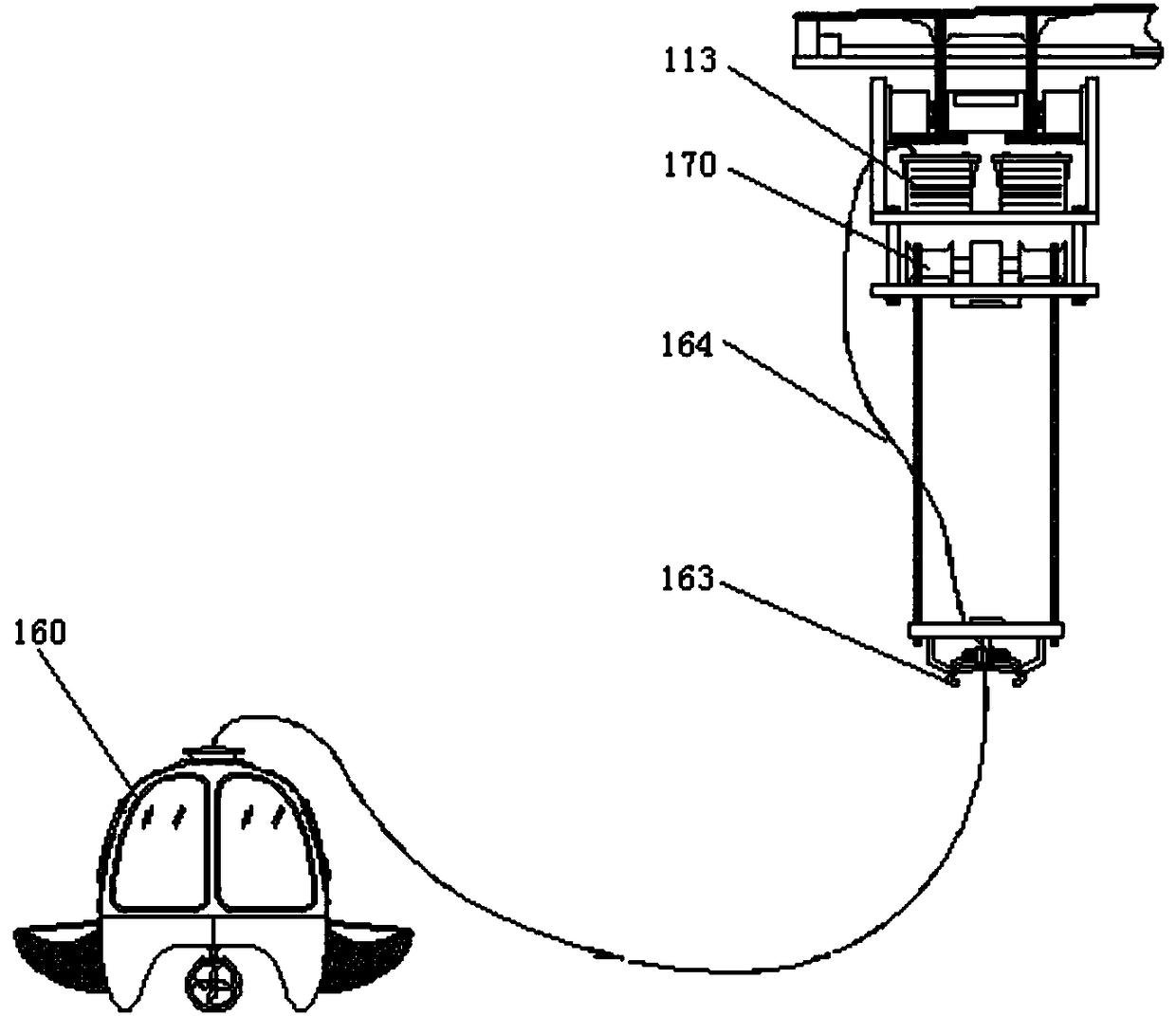

[0042] Such as figure 2 and image 3 As shown, the lifting module 170 includes a hoisting platform 172 and a winch 171 installed on the suspension bracket, the hoisting platform 172 is connected to the winch 171 by a wire rope, and the top of the hull 160 is installed by a caliper mechanism 163 At the bottom of the hoisting platform 172.

[0043] When the work of salvaging floating objects (or dead fish) on the water surface needs to be performed, the manager stops the moving platform from advancing on the track, the winch motor of the lifting module 170 runs, and the winch 171 lowers the wire rope, and the horizontal hoisting platform 172, the caliper mechanism 163 and The hull 160 is lowered to the water surface together, the motor equipped on the caliper mechanism 163 runs, the caliper loosens the anchoring device on the top of the hull 160, and the hull 160 breaks away from other modules and components of the cen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com