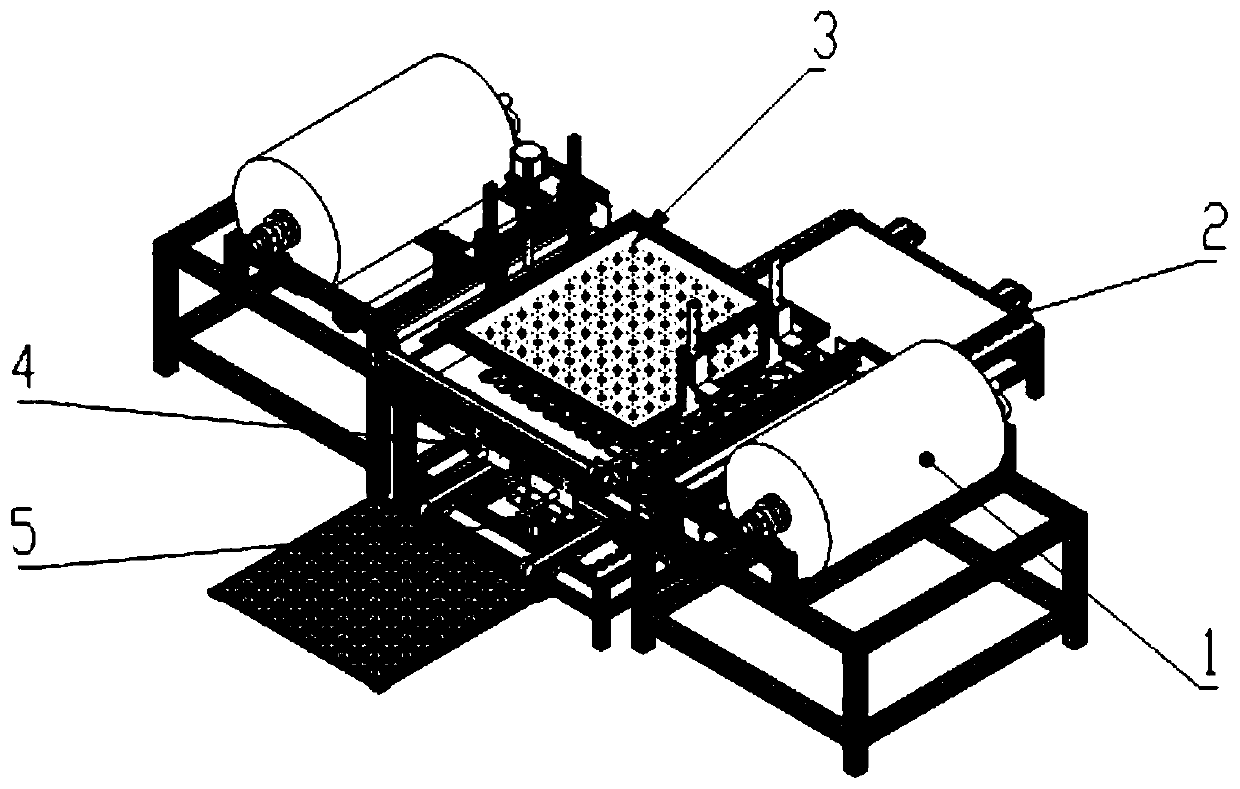

A device for automatically sorting and placing paper on petri dishes

An automatic sorting and petri dish technology is applied in the direction of packaging material feeding device, packaging, transportation packaging, etc. It can solve the problems of difficulty in meeting large-scale production and experiments, inability to automatically sort and pack petri dishes, and low degree of automation. Meet the effect of large-scale production and experiment, compact structure and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0034] The technological process of a device for automatically sorting and placing paper on petri dishes provided by the present invention is as follows:

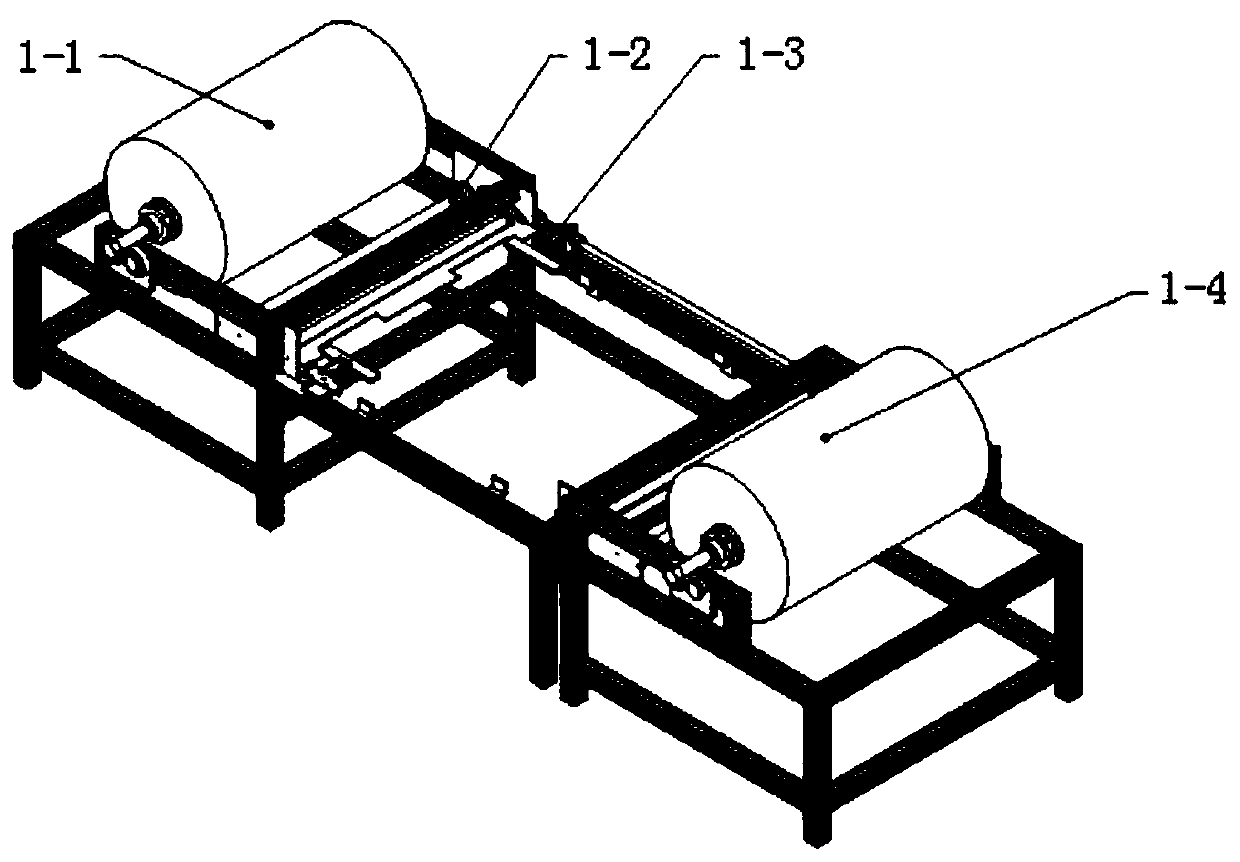

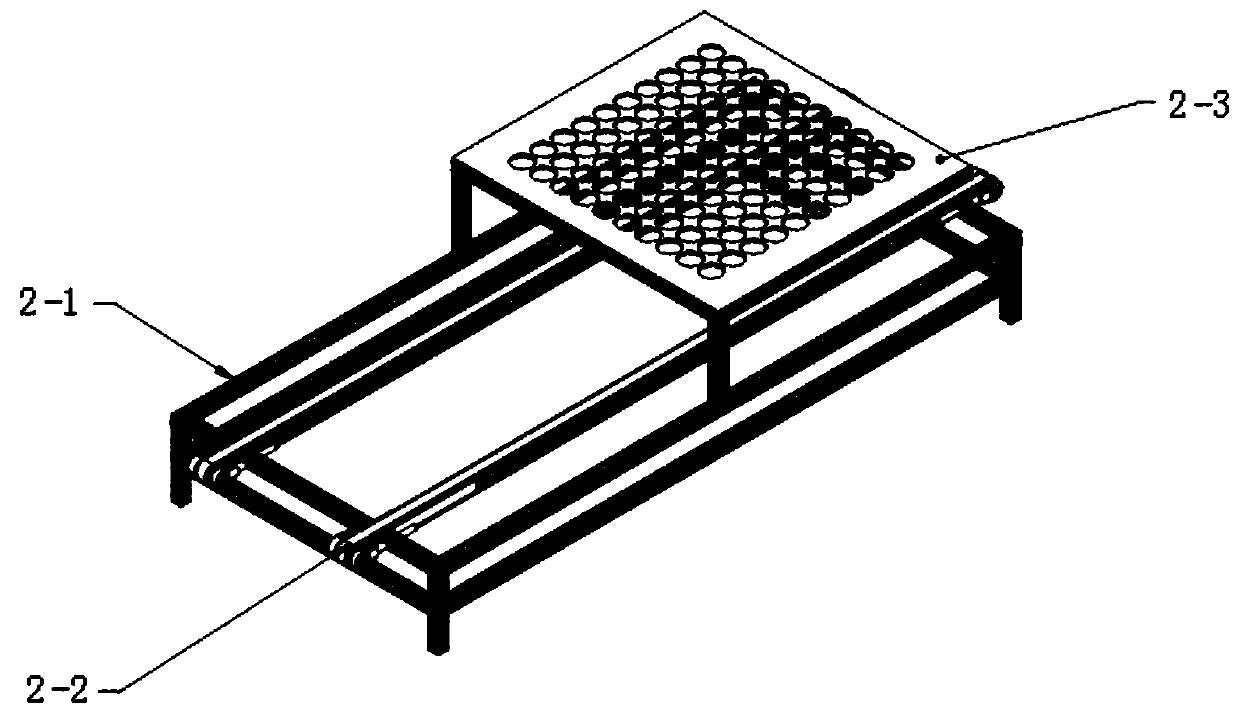

[0035] First, the tray conveying component transports the empty tray to the top of the lifting tray component and then stops. The lifting tray component pushes the tray up and passes it to the sorting push component; next, the sorting push component fills the empty tray with the petri dish, and the petri dish First sorted by the conveyor belt, after being sorted into a row, push a row of petri dishes into the tray until the tray is full; when the tray is full, the tissue paper die-cutting unit cuts the tissue paper downwards, and the cut tissue paper falls into the petri dish, and then the The lifting tray assembly lowers the culture dish loaded with tissue paper and the tray full of culture dish, and is transported out by the tray conveying assembly; at this time, the tissue paper assembly rotates to remove the remaining wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com