A Straw Harvesting, Crushing and Returning Machine

A straw and frame technology, applied in the field of straw harvesting, crushing and returning machines, can solve the problems of not having the functions of straw collection and stubble harvesting, low efficiency of straw crushing, easy entanglement of crushing knives, etc., to meet the needs of large-scale and high-efficiency operations demand, realize the utilization of straw fertilizer, and the effect of thorough crushing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] A straw harvesting, crushing and field returning machine of the present invention will be further described below in conjunction with the accompanying drawings.

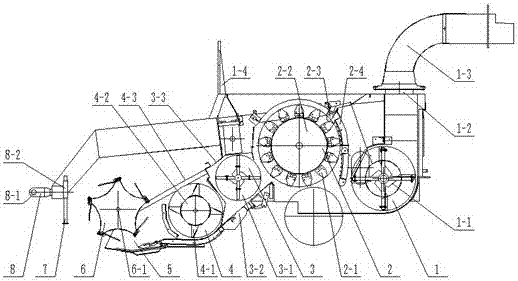

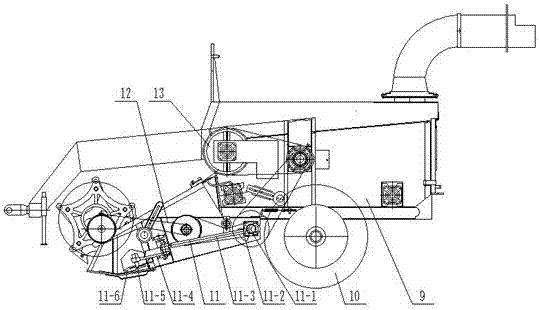

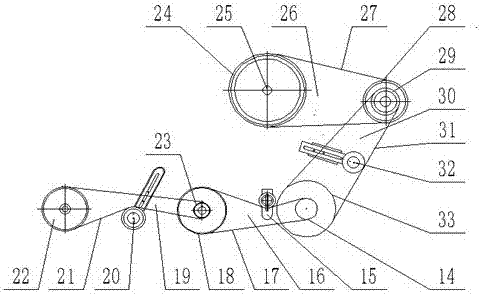

[0022] Such as figure 1 , figure 2 Shown: a straw harvesting, smashing and returning machine, consisting of a frame 9 and a reel 6 assembled on the frame 9 from front to back, a cutting assembly 11, a feeding assembly 4, a conveying assembly 3, Crushing assembly 2, grass discharge assembly 1 and transmission mechanism 12 form.

[0023] During operation, the reel 6 transfers the crop stalks to the cutting assembly 11, and after the cutter 11-6 cuts the crop stalks, the reel 6 transfers the crop stalks to the feeding assembly 4, and the feeding drum 4-2 transfers the cuttings to the cutting assembly 11. The lower crop stalks are gathered together, and the telescopic finger 4-1 on the feeding drum 4-2 sends the crop stalks to the inclined conveyor 3-2, and then the crop stalks are transported to the conveyor u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com