Copper wire feeding device

A copper wire and rack technology is applied in the field of copper wire feeding devices, which can solve the problems of copper wire winding and disconnection, and achieve the effect of preventing copper wire winding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

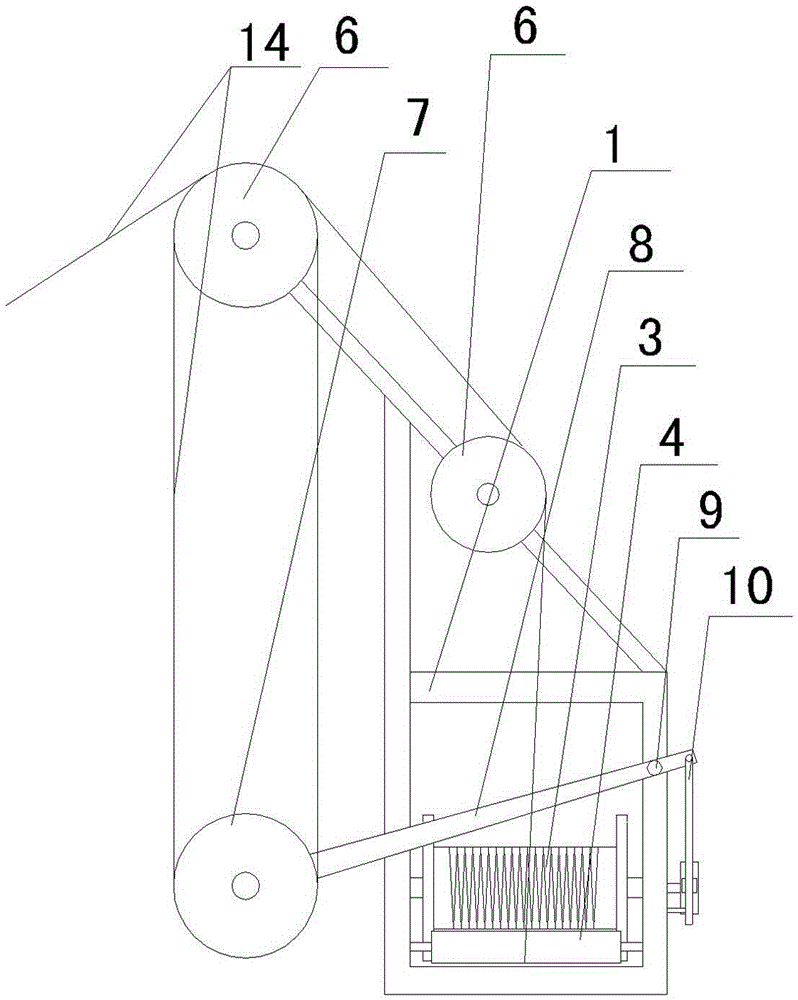

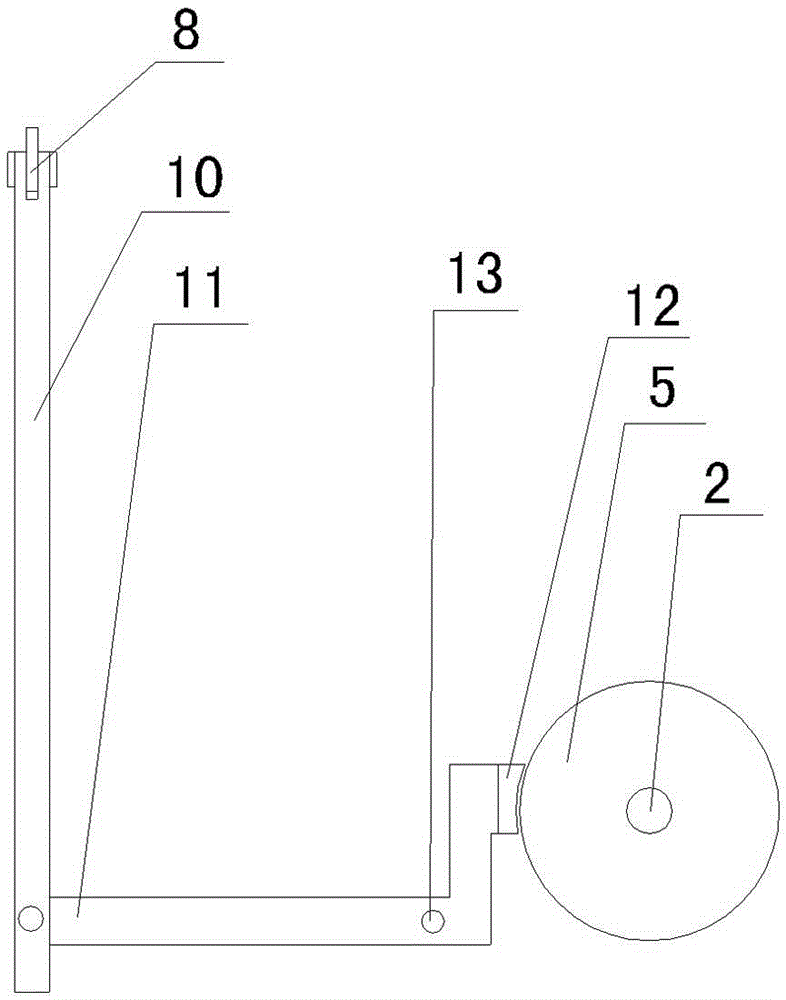

[0010] See figure 1 , figure 2 As shown, a copper wire feeding device includes a frame 1, a reel fixed shaft 2 and a roller 4 corresponding to the reel 3 are arranged on the frame 1, and a guide is installed on the upper end of the corresponding roller 4 on the frame. Runner, brake disc 5 is installed on one side of the fixed shaft 2 of the reel, the guide runner includes a fixed runner 6 and a movable runner 7, and the outer edge of the fixed runner 6 has at least two annular grooves, preferably a fixed runner 6 has four annular grooves, and the movable runner 7 has three annular grooves, so that the copper wire can be wound three times to reduce the pressure of the copper wire hanging the movable runner 7. The fixed runner 6 is installed on the upper end of the frame 1, and the movable The runner 7 is installed on one end of the support rod 8, the support rod 8 is installed on the frame 1 through the first rotating shaft 9, the other end of the support rod 8 is hingedly co...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap