Method for optimizing steam distribution curves of steam turbines on basis of data mining technologies

A data mining, steam turbine technology, applied in mechanical equipment, engine components, machines/engines, etc., can solve the problems of steam turbine load fluctuation, poor primary frequency modulation quality, load jump, etc., to achieve the effect of solving load fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

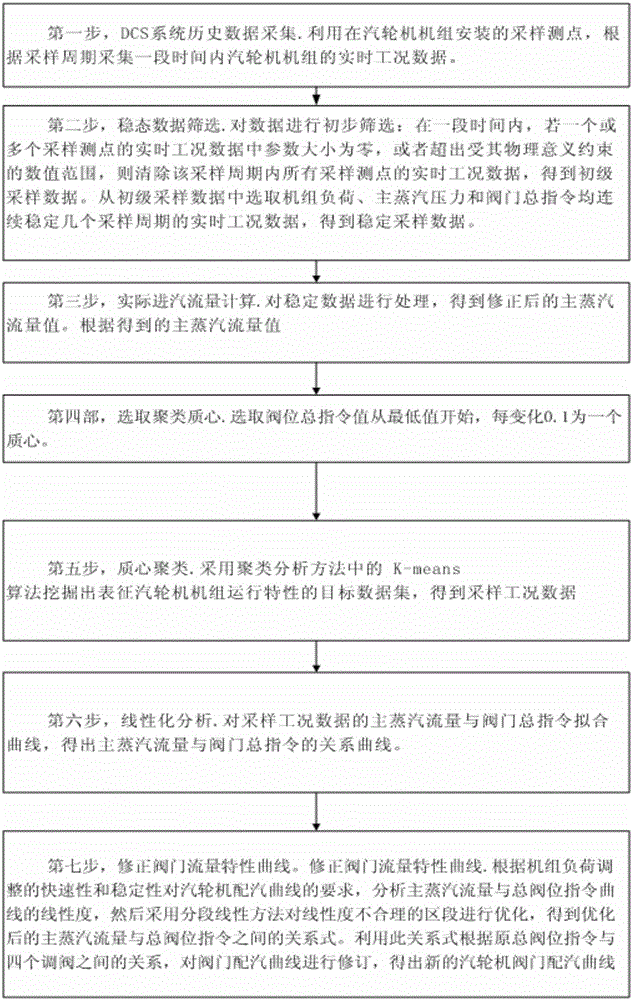

[0018] Such as figure 1 As shown, a kind of steam turbine distribution curve optimization method based on data mining technology described in the present invention comprises the following steps:

[0019] The first step is the historical data collection of the DCS system. Use the sampling measuring points installed in the steam turbine unit to collect real-time working condition data of the steam turbine unit within a certain period of time according to the sampling period.

[0020] As shown in Table 1, the data acquisition parameters of the present invention include: ref (total valve position command), load (unit load), mainpress (main steam pressure), 1STPRESS (adjustment stage pressure), MSTEAMFLOW (main steam flow), CV1POS ( #1 high-profile valve opening), CV2POS (#2 high-profile valve opening), CV3POS (#3 high-profile valve opening), CV4POS (#4 high-profile valve opening), MATCMSTEAMTEMPL (left side of main steam temperature), ATCMSTEAMTEMPR (main steam temperature steam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com