A hopper with picking function

A hopper and functional technology, applied in the field of feeding equipment, can solve the problems of short size and inconvenience for operators to pre-arrange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

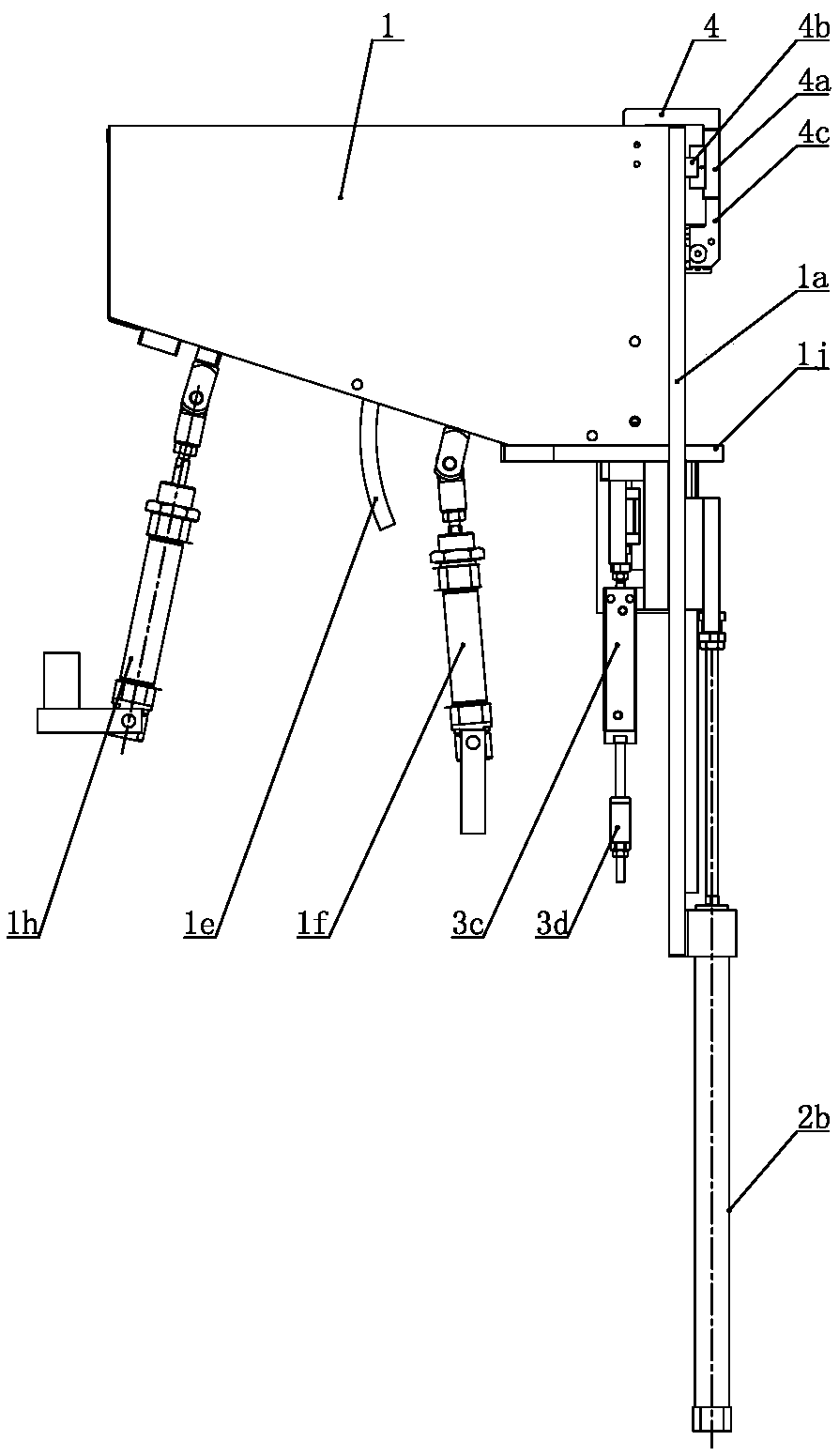

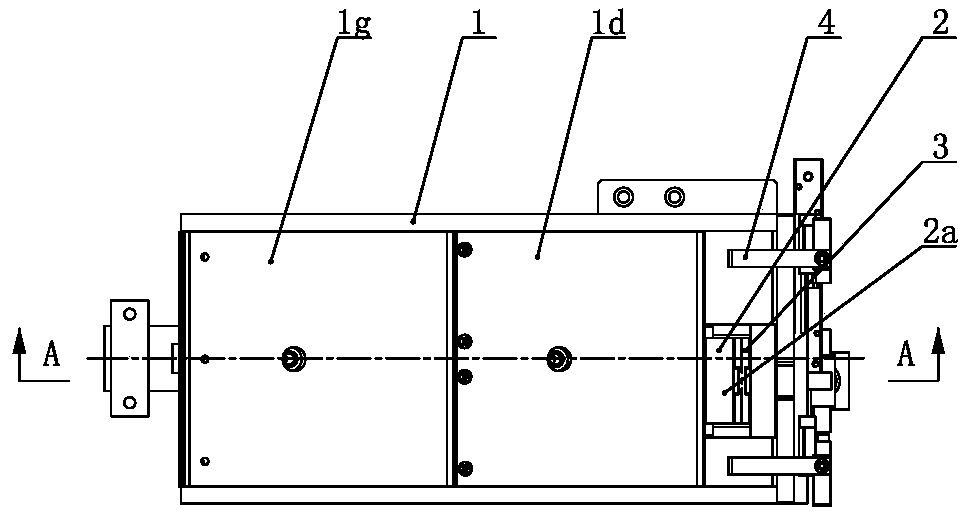

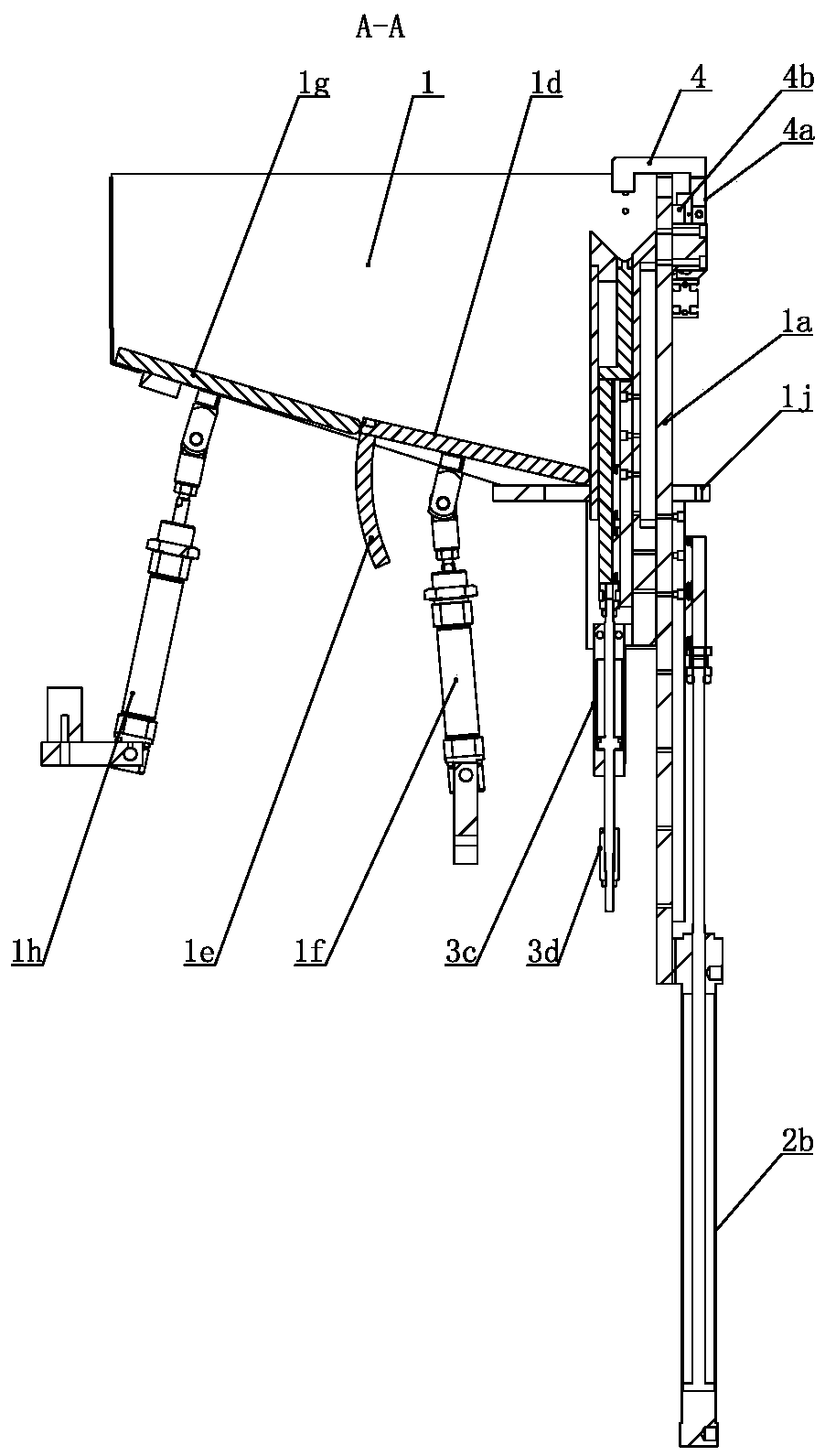

[0028] like figure 1 and Figure 8 As shown, the hopper with picking function of the present invention includes a hopper body 1. The bottom of the hopper body 1 is provided with a hopper inclined bottom plate whose right end is inclined downward. The middle part of base plate 1j front and rear direction is provided with material holding hole, is provided with in the holding hole and can slide up and down along the left end face of hopper right wall plate 1a the lifting big slider 2, and the lower end of lifting big sliding block 2 is by big sliding block. Driven by the air cylinder 2b, the top of the large slider 2 is provided with a large V-shaped groove 2a extending along the front and rear directions; The upper end abuts against the left end surface of the right wall panel 1a of the hopper.

[0029] Lifting the large slider 2 is initially at a low position, and the upper port of the supporting hole is exposed; the right end of the inclined bottom plate of the hopper is in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com