A feeding mechanism for short cylindrical materials

A material and cylinder technology, applied in the field of feeding equipment, can solve the problems of inconvenience for operators to pre-arrange, short size, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

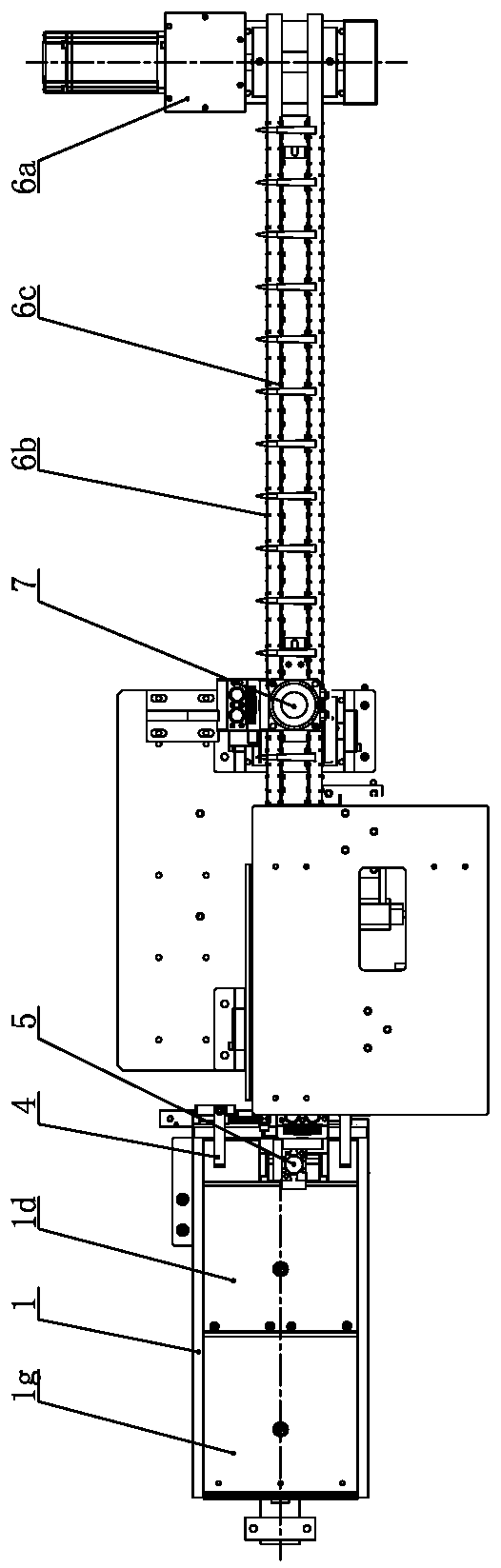

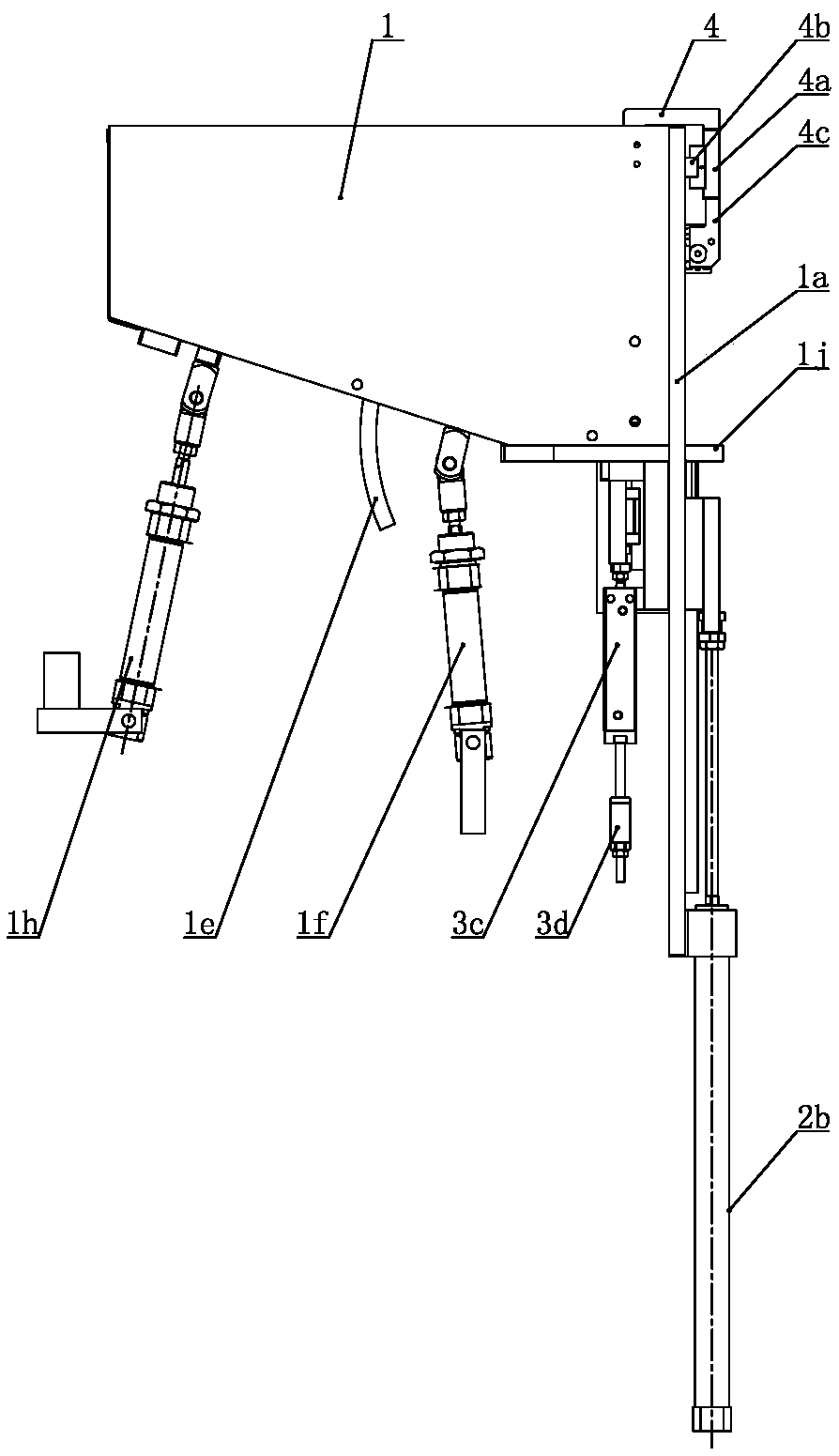

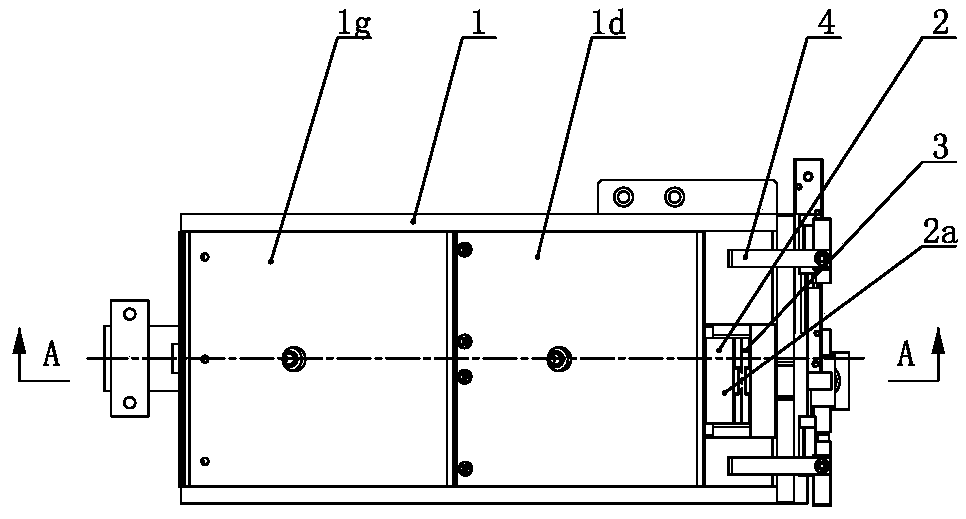

[0034] Such as figure 1 and Figure 10 As shown, the feeding mechanism for short cylindrical materials of the present invention includes a hopper 1 supported on the frame, and the right side of the hopper 1 is provided with two rows of chains 6b that are respectively wrapped around the driving sprocket and the driven sprocket and are parallel to each other. , the two chains 6b are provided with one-to-one corresponding material support V-shaped frame 6c, the opening of the material support V-shaped frame 6c is upward and evenly distributed along the length direction of each chain 6b, and the two driving sprockets are jointly installed on the conveyor servo motor 6a. On the output shaft, the upper and lower sides of the upper chain are provided with matching upper probes 6d and lower probes 6e. The left end of the chain 6b is provided with a grasping and conveying mechanism 5 for transferring the short cylindrical material from the hopper 1 to the material supporting V-shaped ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com