Novel plough type discharging device

A plow unloading, a new type of technology, applied in the field of new plow unloading devices, can solve the problems of difficult installation, residue, large installation space, etc., and achieve the effect of good unloading effect, simple structure, and small installation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

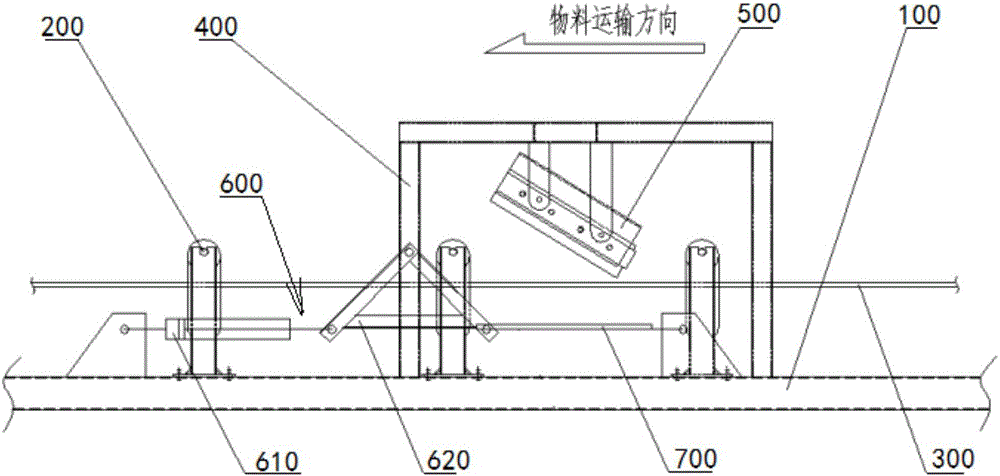

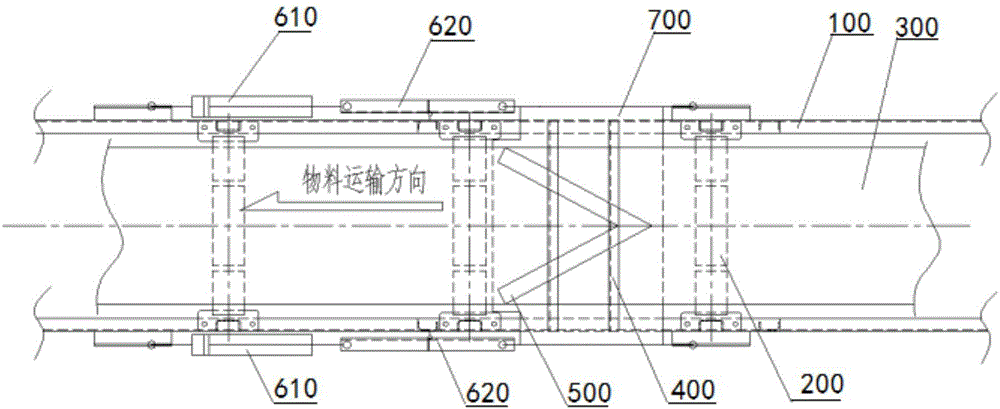

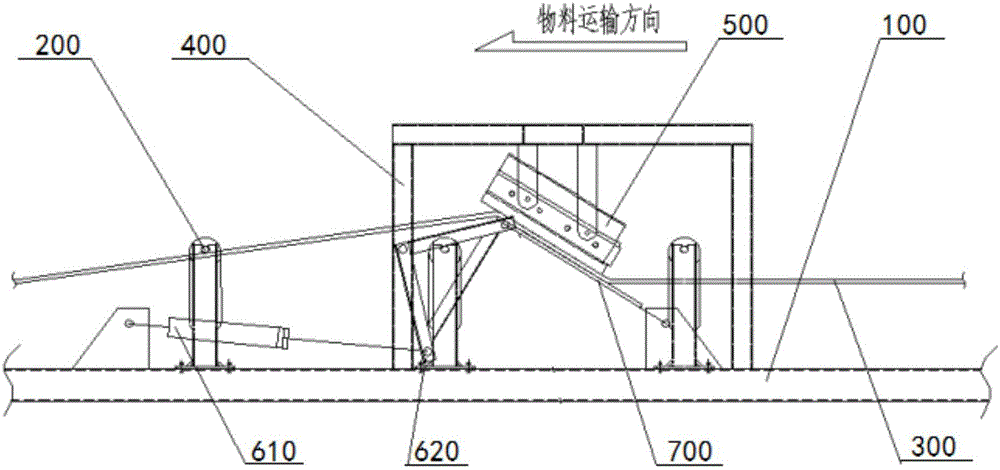

[0020] see Figure 1 to Figure 3 A new type of plow unloading device is shown, including intermediate frame 100, idler roller group 200, conveyor belt 300, frame structure 400, coulter 500, lifting device 600, hydraulic cylinder 610, connecting assembly 620, supporting member 700 .

[0021] The idler group 200 is set on the intermediate frame 100 to support the weight of the conveyor belt 300 and the carrying material. The frame structure 300 is set on the intermediate frame 100. On the frame structure 400, there is a fixed angle between the frame structure 400 and the horizontal plane. Coulter 500.

[0022] The new plow unloading device also includes at least one set of lifting device 600, and the lifting end of the lifting device 600 is provided with a supporting part 700, which is hinged with the supporting part 700, and the supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com