Large-ventilation-quantity machine room ventilation floor comprising inlaid-type adjustor

A regulator and ventilation volume technology, which is applied to local access floors, ventilation systems, space heating and ventilation, etc., can solve the problems of small opening ratio, large thickness, easy cracking, etc., and achieve convenient air volume adjustment and structural design simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

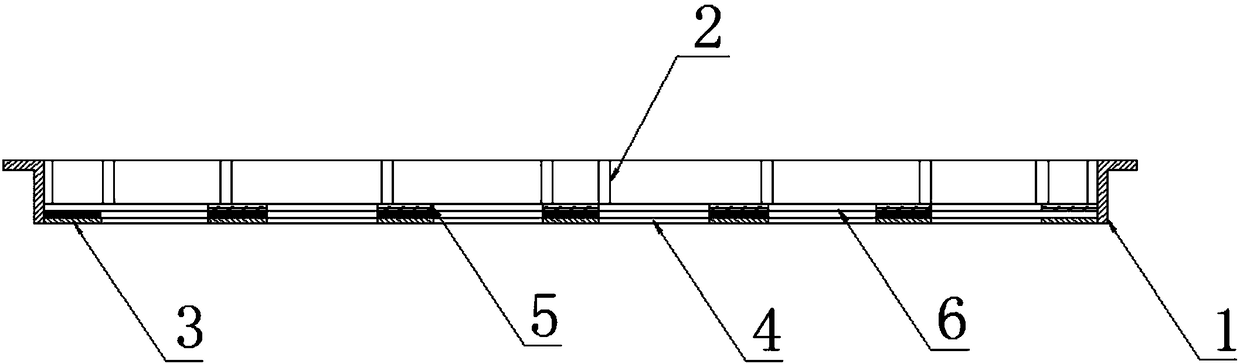

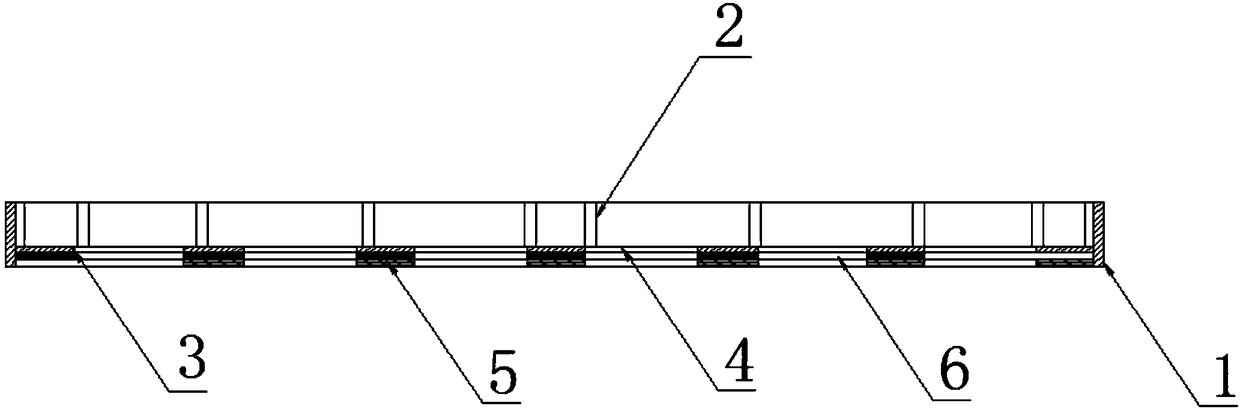

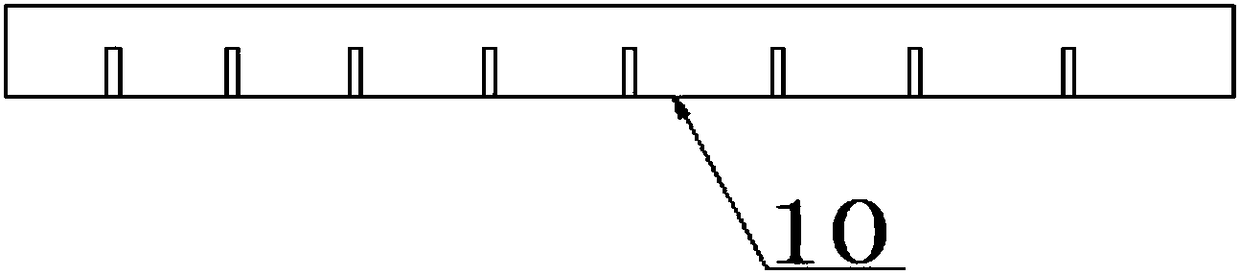

[0032] like figure 1 As shown in or 2, Embodiment 1 of the present invention provides a machine room ventilation floor with built-in regulators and a large ventilation volume, including a floor frame 1 and a grid panel 2 arranged in the floor frame 1, wherein the floor frame 1 The four sides can be in a square structure or an L-shaped flash structure, for example, a corner plate can be used; such as image 3 As shown, the grid panel 2 can be a panel with a through-hole structure formed by a plurality of horizontal and vertical inserts 10 plugged together, or can be a hollow panel or casted integrally with the floor frame 1 through a model.

[0033] The floor frame 1 is provided with a ventilation volume regulator at the bottom of the grille panel 2. The grille panel 2 is covered above the ventilation volume regulator. Compared with the existing air volume adjustment device, it not only has a large adjustment range, but also does not automatically change the air volume once th...

Embodiment 2

[0040] like Figure 4-10 As shown, Embodiment 2 of the present invention further provides, on the basis of Embodiment 1, a machine room ventilation floor with built-in regulators and a large ventilation volume. The movable sliding vanes 7 are provided, and a plurality of wind shielding strips 5 are arranged on the two movable sliding vanes 7, and the sum of the total area of the wind shielding strips 5 on the two movable sliding vanes 7 is equal to the sum of the total areas of several ventilation holes 4. ;

[0041] The two movable sliding sheets 7 slide left and right along the edge of the fixed ventilation sheet 3 through the sliding assembly, and make the corresponding windshield strips 5 on the two movable sliding sheets 7 cooperate to close or open the ventilation holes 4 . The two movable sliding sheets 7 are overlapped with each other and can slide relative to each other through the sliding assembly. The wind blocking strips 5 on the two movable sliding sheets 7 can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com