A glass bottle annealing furnace

An annealing furnace, glass bottle technology, applied in glass production and other directions, can solve the problems of different heat dissipation rates of the inner wall and outer wall of the glass bottle, affecting the appearance and yield of the glass bottle, and different stress and strain rates of the inner wall and outer wall of the glass bottle, etc. The effect of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below by means of specific embodiments:

[0018] The reference signs in the accompanying drawings of the specification include:

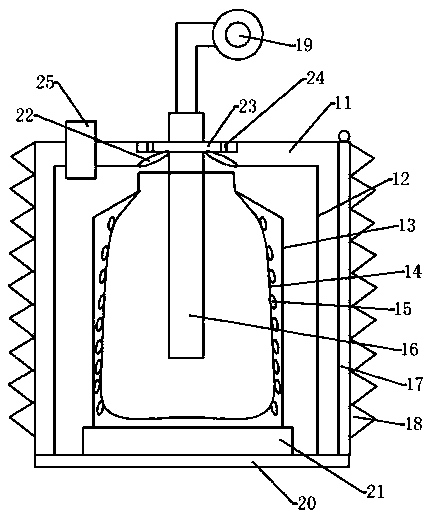

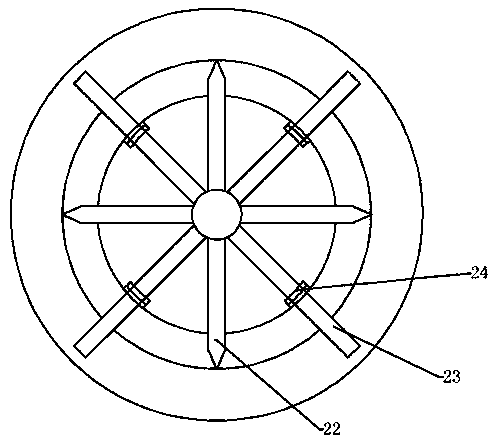

[0019] Annealing furnace 11, shroud 12, glass bottle 13, air bag 14, protrusion 15, air duct 16, furnace door 17, electric coil 18, blower 19, cover bottom 20, workbench 21, front fan blade 22, rear fan Leaf 23, balance nut 24, chimney 25.

[0020] Such as figure 1 A glass bottle annealing furnace shown includes an annealing furnace 11 and a workbench 21. The workbench 21 is placed at the bottom of the annealing furnace 11. A workpiece is arranged on the workbench 21. An air bag 14 is arranged inside the workpiece. There are 20 exhaust holes with a diameter of 1 mm. The outer surface of the airbag 14 is provided with a protrusion 15. The protrusion 15 is zinc metal with a smooth curved surface. The airbag 14 is pierced with a metal air guide tube 16. The air guide tube 16 is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com