Socks knitting machine universal hood device for flat and terry

A technology for knitting hoods and hosiery machines, which is applied in knitting, weft knitting, textiles and papermaking, etc. It can solve the problems of low knitting efficiency, solve the problem of reverse yarn, and avoid the effect of pulling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

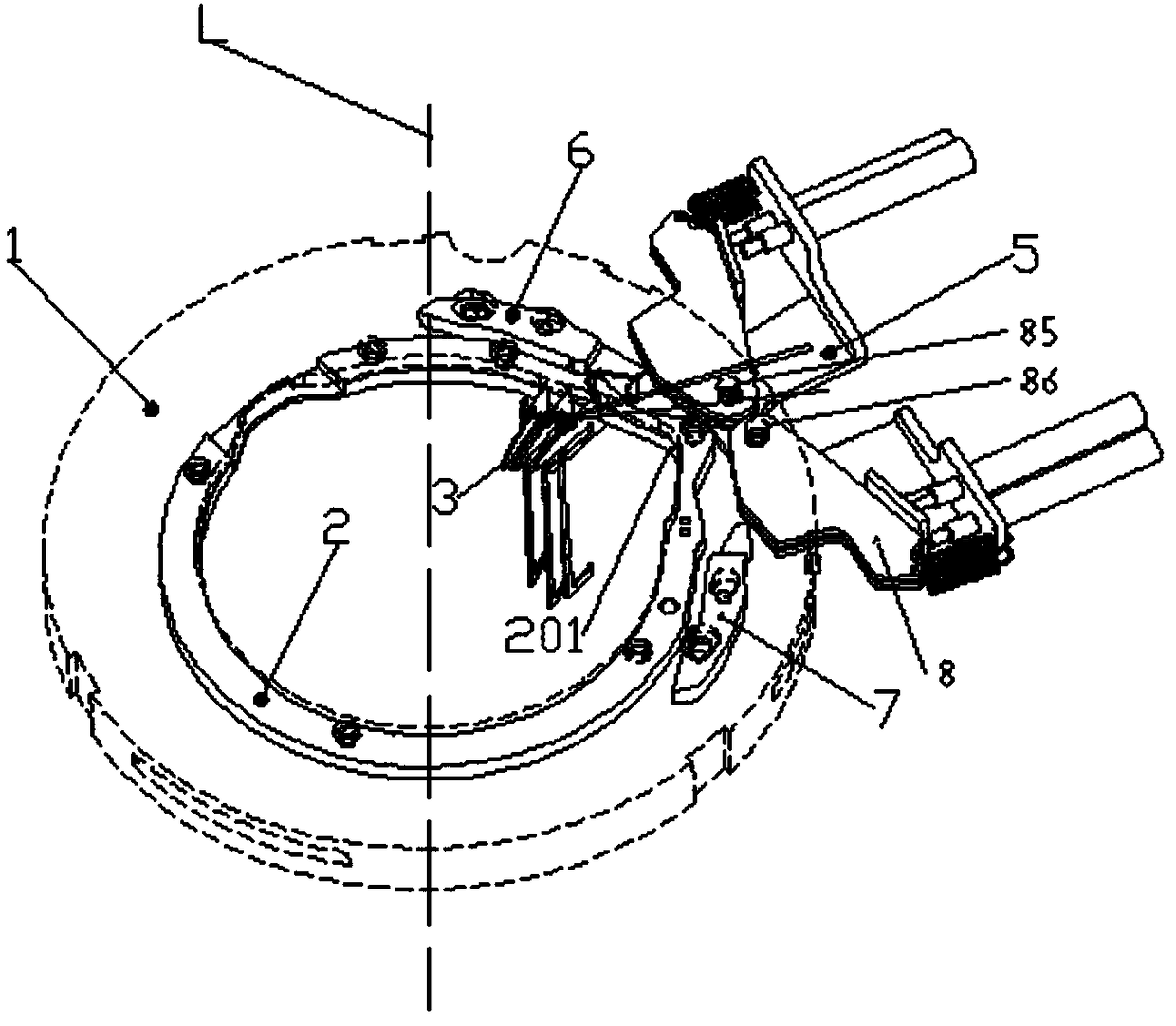

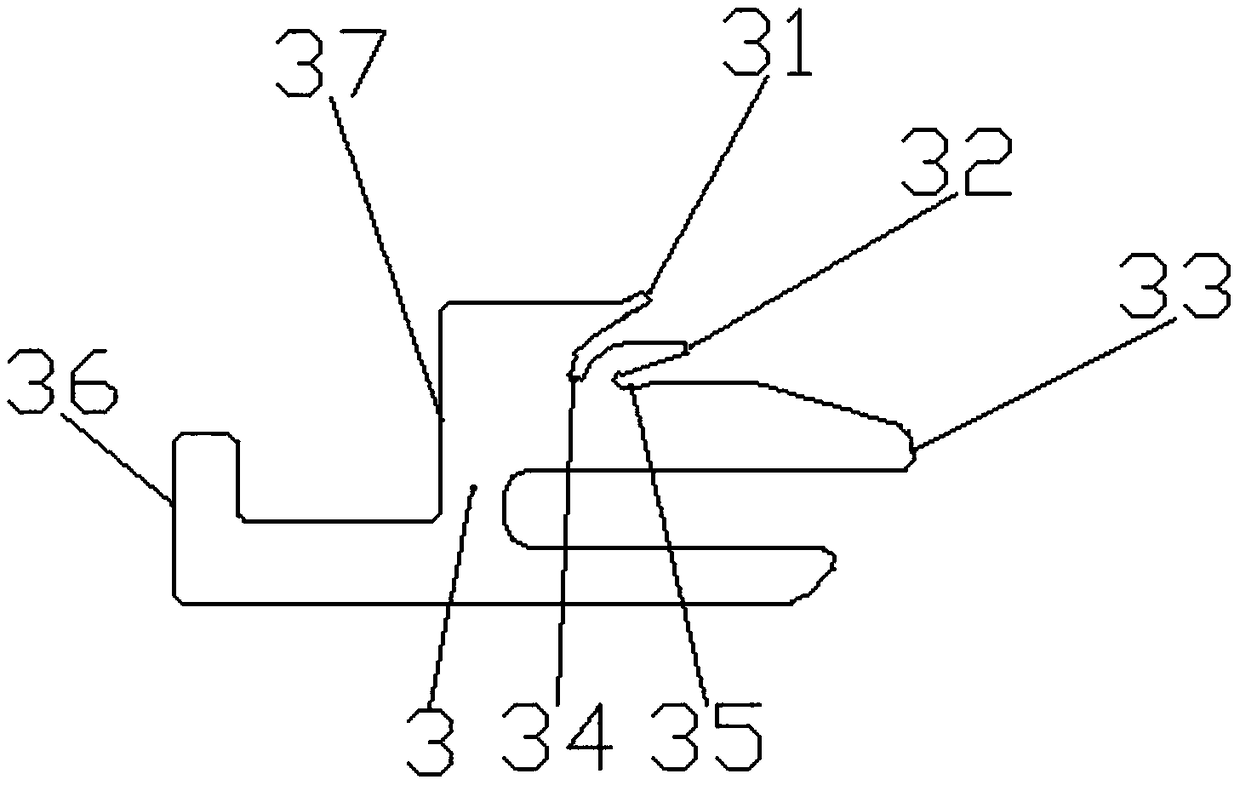

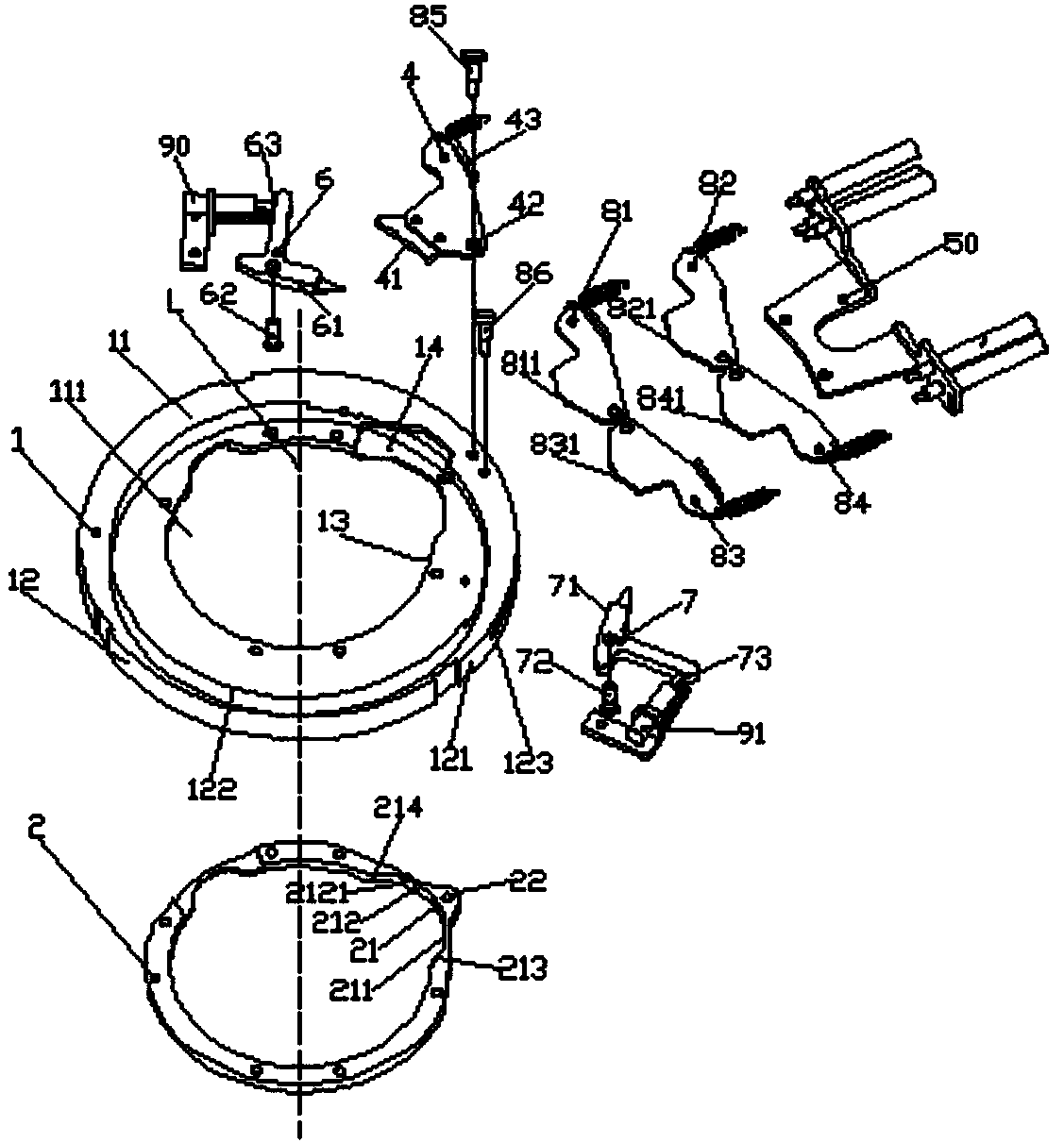

[0024] Example 1: as attached figure 2 and attached image 3 As shown, the present invention cooperates with the terry raw gram sheet 3 to carry out the weaving operation, and the terry raw gram sheet 3 has a piece forehead portion 31, a piece tongue portion 32, a piece jaw portion 33, a piece nose 34, a piece throat 35, and the back works face 37, end credit face 36;

[0025] The present invention includes a lid-shaped raw gram cover 1, an eyebrow ring 2 fixedly connected with the raw gram cover 1, a flat plate cam 4 and a terry loop cam 8 pivoted on the raw gram cover 1 and controlled by a cam control device 50. The left eyebrow 6, which is controlled by the left eyebrow control device 90 in the raw hood 1, is pivoted on the raw hood 1 and is controlled by the right eyebrow control device 91; the right eyebrow 7;

[0026] The raw material cover 1 has a top plate 11, a peripheral wall 12 extending downward along the peripheral edge of the top plate 11, and a ring groove 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com