Cantilever type bridge repair and maintaining platform

A cantilever, bridge technology, applied in the direction of bridges, bridge parts, bridge construction, etc., can solve problems such as affecting the normal passage of roads, wasting manpower and material resources, increasing traffic burdens, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings.

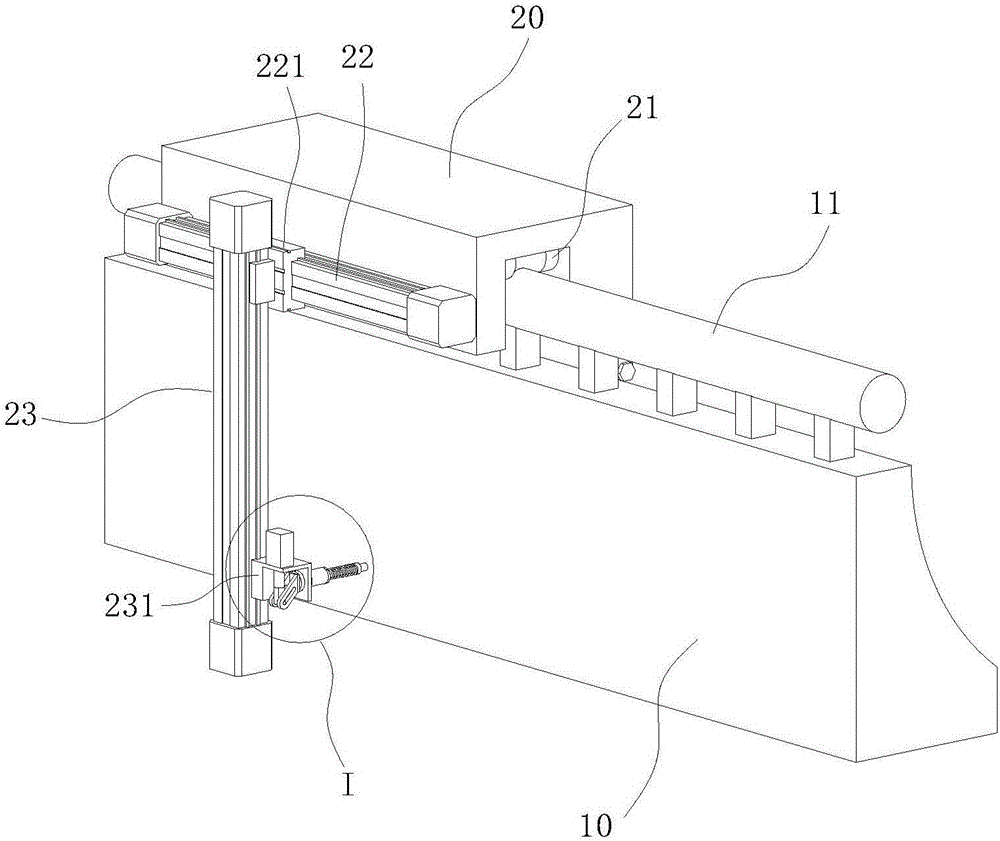

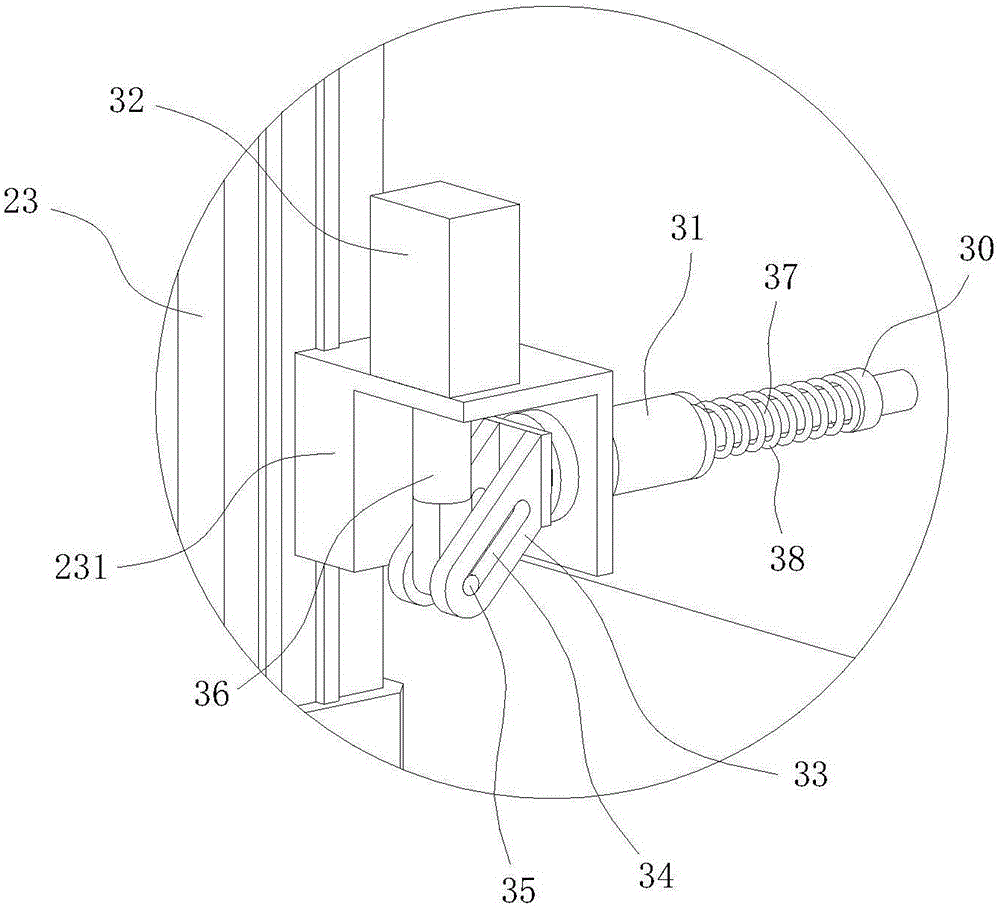

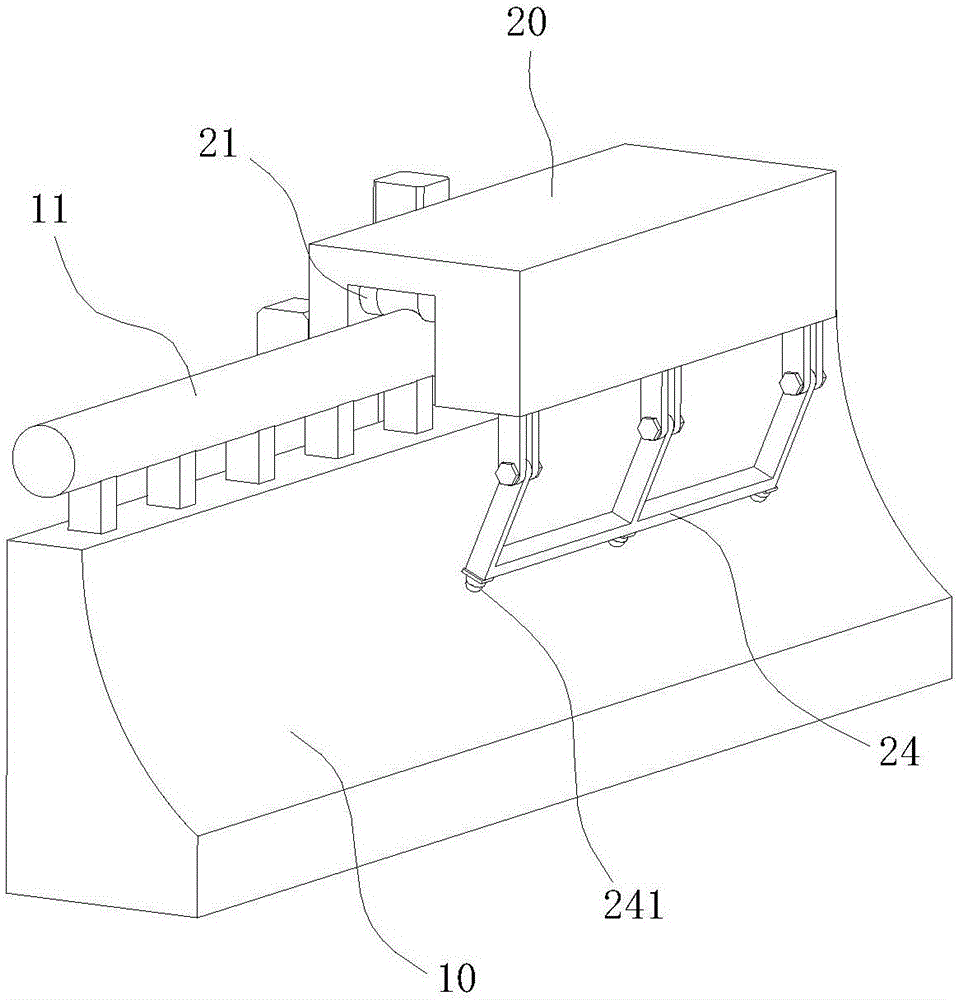

[0019] Such as figure 1 As shown, a cantilever bridge repair and maintenance platform includes a flaw detection device and a walking mechanism. The device is suspended outside the cement guardrail 10 , and the probe 30 of the flaw detection device is set facing the outer wall of the cement guardrail 10 . The present invention uses the steel pipe 11 on the top of the bridge guardrail as a track, so that the flaw detection device can automatically move along the guardrail, without manual transportation of the flaw detection equipment, and without affecting the normal passage of the road.

[0020] Preferably, the walking mechanism includes a walking frame 20, the walking frame 20 is provided with a roller 21, and a driving device for driving the roller 21 to rotate, and the driving device is located on the inner side of the cement guardrail 10 to balance the flaw detec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com