Movably connected road shoulder

A technology of movable connection and road shoulder, which is applied in the direction of gutters/curbs, climate change adaptation, etc., can solve the problems of shortened service life of the main road surface, narrow road shoulders, non-standard roads and road shoulders, etc., to shorten the construction period, The effect of reducing the amount of work and shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

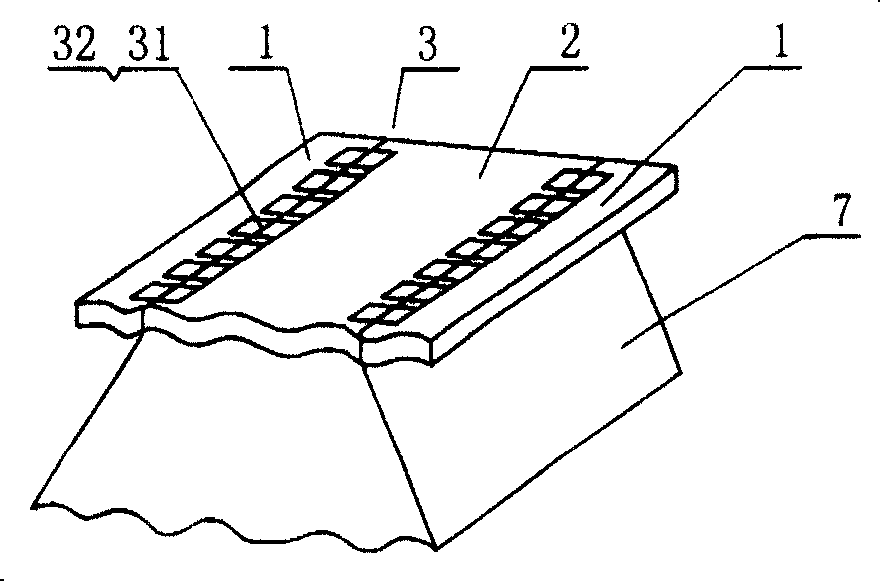

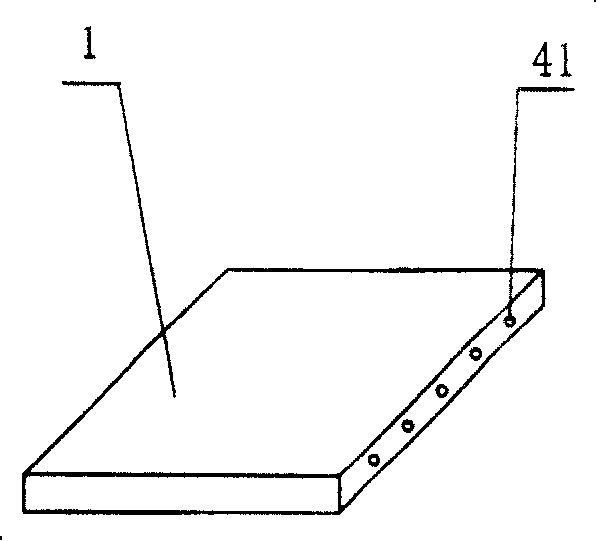

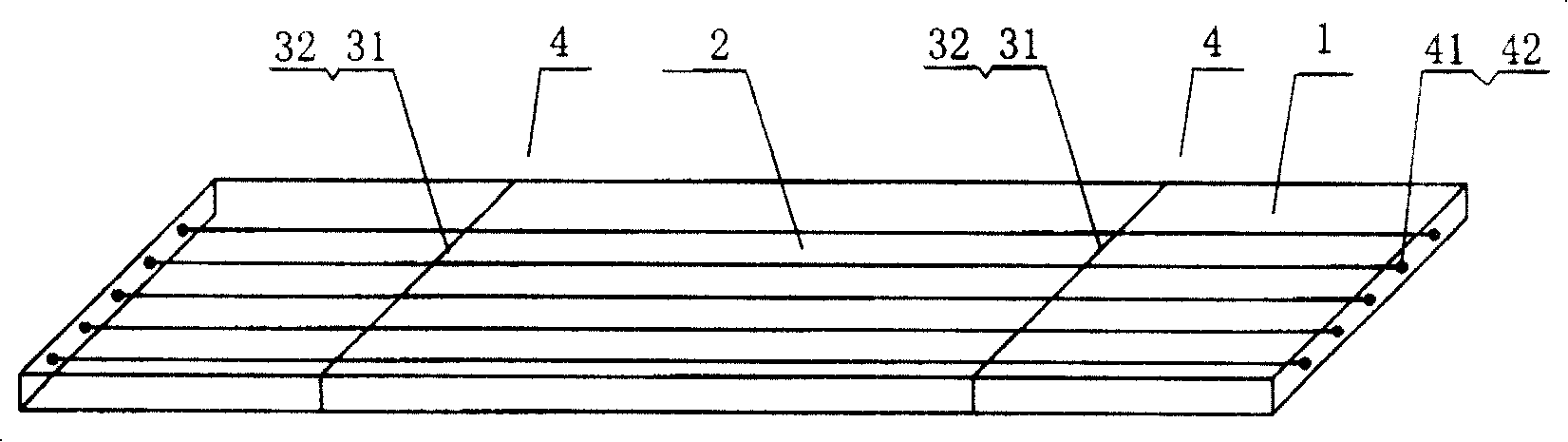

[0035] see figure 1 , Figure 16 , a movably connected road shoulder, comprising a road shoulder 1 and a concrete road slab 2 connected to the road shoulder 1, wherein the connection between the road shoulder 1 and the concrete road slab 2 is provided with a movable and fixed connection device 3, and the connection device 3 includes a plug-in connection device 4. Riveting connection device 5 and lap connection device 6, which are composed of embedded parts 31 arranged at the joint between road shoulder 1 and concrete road slab 2 and movable parts 32 used as fixed connections.

[0036] figure 2 , image 3As shown, the embedded parts 31 of the plug-in connection device 4 are several through-holes 41 that are vertically arranged in the prefabricated road shoulder 1 and the pouring concrete road slab 2, and the through-holes 41 are fixedly connected. The movable part 32 is an inserted steel bar or steel wire bundle 42 . Due to the tension at the joint, the steel bar or steel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com