Facility and process for stably supporting steeply inclined mining roadway surrounding rock

A technology of mining roadway and steep inclination, which is applied to mining equipment, tunnels, tunnel linings, etc., can solve problems affecting normal production, torsion, bottom drum, etc., and achieve the effect of promoting further improvement, promoting research level, and expanding research fields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0046] The present invention carries out experimental implementation, and its experimental implementation conditions are as follows:

[0047] Mine mining roadway has the following characteristics:

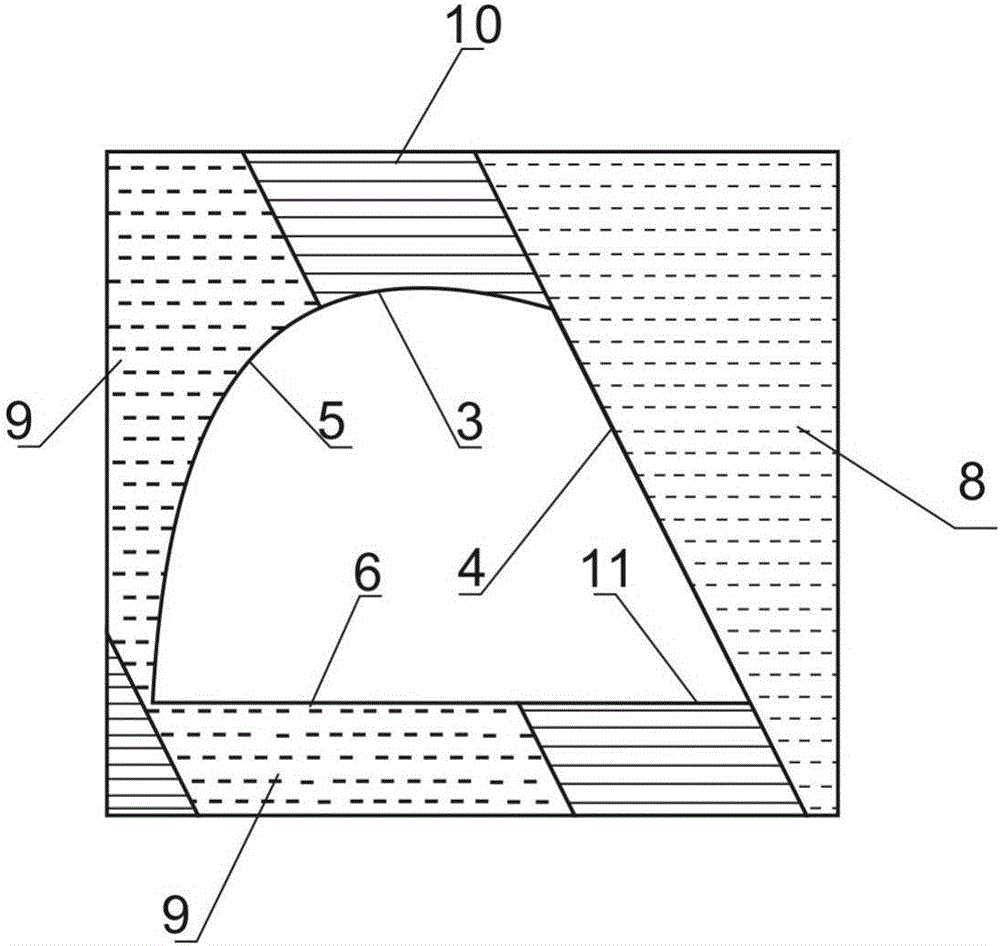

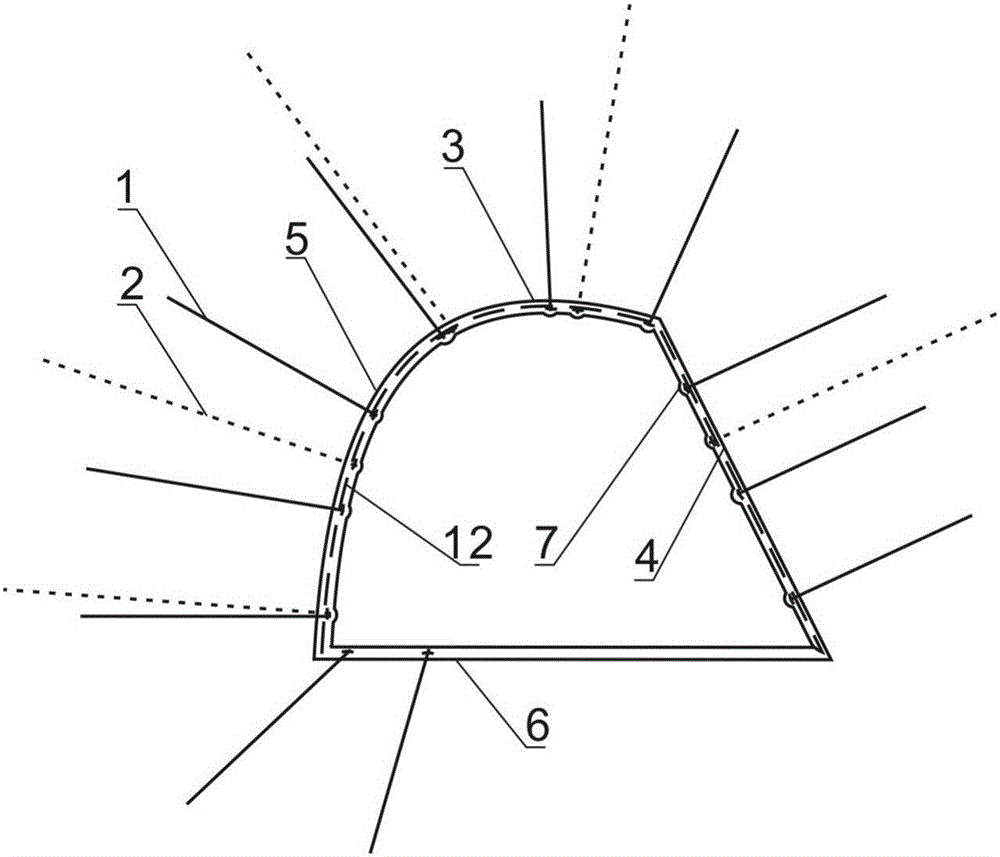

[0048] (1) All belong to half-coal rock roadway, and the roof and floor of the roadway have the characteristics of half-coal rock, and the two sides of the roadway are the roof and floor of the coal seam, which is completely different from the general dipped coal seam.

[0049] (2) The coal and rock mass where the roadway is located has low strength and a large inclination angle (average 64°). The roof and floor are all muddy and carbonaceous weak rocks. The distance between the bottom plate and the next coal seam is only 1.78m, and the distance between some sections is only 0.3m .

[0050] (4) The recovery roadway should be used not only as the transportation roadway of the coal seam in the coal mining section, but also as the return air roadway of the coal seam working face in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Breaking force | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com