Synchronous water-temperature adjustment valve core structure

A technology of synchronous adjustment and spool, applied in the direction of valve details, multi-way valves, valve devices, etc., can solve the problems of large water inlet obstruction, short life, poor sealing, etc., and achieve the effect of simple valve body structure and reduced cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

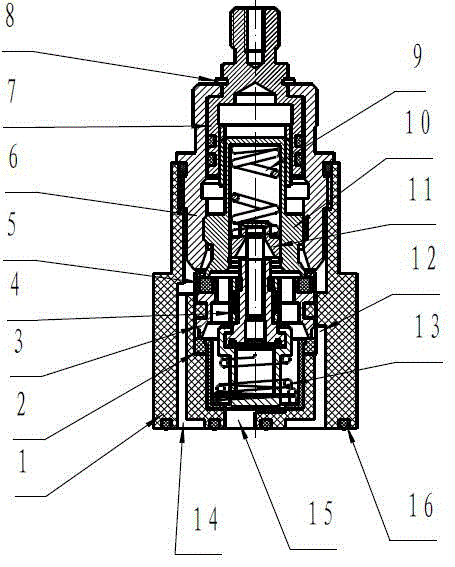

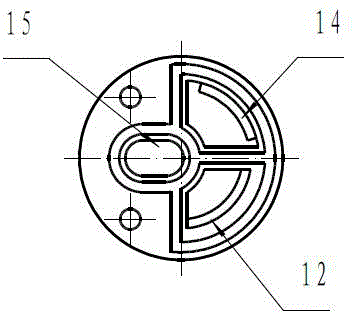

[0019] see figure 1 and figure 2 As shown, the present invention includes a valve core lower sleeve 1, a valve core upper sleeve 6, an adjustment knob 7 and an adjustment slider 10, and the valve core lower sleeve 1 is provided with a hot water inlet channel 12 and a cold water inlet channel 14 and the mixed water outlet channel 15, the water inlet port of the hot water inlet channel 12, the water inlet port of the cold water inlet channel 14 and the water outlet port of the mixed water outlet channel 15 are all located at the bottom of the lower sleeve 1 of the valve core, and are controlled by the valve The core bottom surface sealing ring 16 is divided. The upper part of the spool lower sleeve 1 is provided with a spool upper sleeve 6, the spool upper sleeve 6 is connected with the spool lower sleeve 1 through a thread mechanism, and an adjustment knob 7 and an adjustment slider 10 are installed inside the spool upper sleeve 6, The adjusting knob 7 is fixed on the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com