Double-head pneumatic spray gun testing method

A testing method and automatic testing machine technology, applied in the testing of mechanical components, testing of machine/structural components, measuring devices, etc., can solve problems such as optimization of use functions, poor spraying effect, and decline in the use of spray guns, and achieve detection Thorough, simple and intuitive detection method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

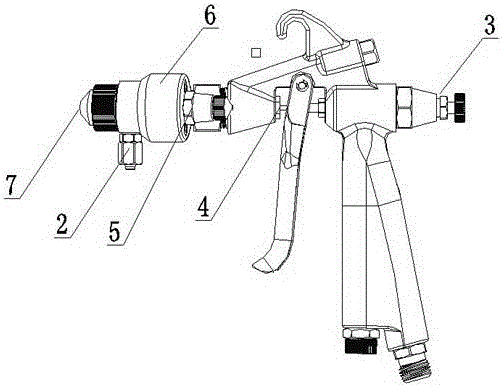

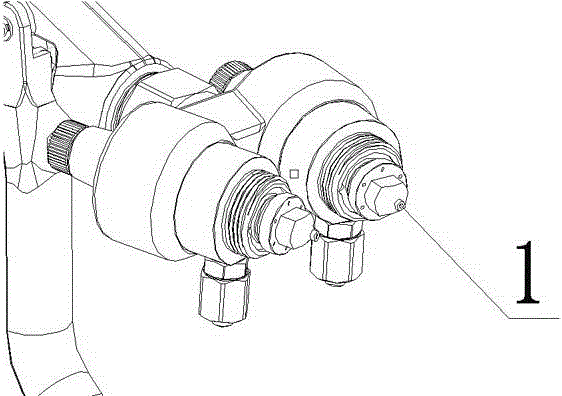

[0025] like figure 1 , 2 As shown, a double-headed pneumatic spray gun test method includes the following steps:

[0026] a. Spray gun service life test: automatic test machine 5000 times cycle test;

[0027] b. Pressure test of spray gun body: Inject gas with a pressure of 8KG into the gun body for 60 minutes;

[0028] c. Sealing test: Connect the air pipe joint, the gas pressure is 3KG, the gun body is immersed in water, and when the oil adjusting screw 3 and air sealing screw 4 are immersed in water, the number of bubbles emerging from their positions is less than 20 per minute, which is qualified ; Observe whether there are bubbles coming out of the inner nozzle 1; when the inner nozzle 1, the hexagon 5, and the AB seat are immersed in water, there should be no bubbles within 1 minute;

[0029] d. Connect liquid with a pressure of 4KG, and observe whether there is liquid leakage at the joint 2 of the liquid pipe;

[0030] e. Spraying test: Check the working status of t...

Embodiment 2

[0032] like figure 1 , 2 As shown, a double-headed pneumatic spray gun test method includes the following steps:

[0033] a. Spray gun service life test: 10,000 cycles of automatic testing machine;

[0034] b. Pressure test of spray gun body: Inject gas with a pressure of 12KG into the gun body for 60 minutes;

[0035] c. Sealing test: Connect the air pipe joint, the gas pressure is 4KG, the gun body is immersed in water, and when the oil adjustment screw 3 and air seal screw 4 are immersed in water, the number of bubbles emerging from their positions is less than 20 per minute, which is qualified ; Observe whether there are bubbles coming out of the inner nozzle 1; when the inner nozzle 1, the hexagon 5, and the AB seat are immersed in water, there should be no bubbles within 1 minute;

[0036] d. Connect liquid with a pressure of 5KG, and observe whether there is liquid leakage at the joint 2 of the liquid pipe;

[0037] e. Spraying test: check the working status of the ...

Embodiment 3

[0039] like figure 1 , 2 As shown, a double-headed pneumatic spray gun test method includes the following steps:

[0040] a. Spray gun service life test: 20,000 cycles of automatic testing machine;

[0041] b. Pressure test of spray gun body: Inject gas with a pressure of 8KG into the gun body for 60 minutes;

[0042] c. Sealing test: Connect the air pipe joint, the gas pressure is 5KG, the gun body is immersed in water, and when the oil adjustment screw 3 and air seal screw 4 are immersed in water, the number of bubbles emerging from their positions is less than 20 per minute, which is qualified ; Observe whether there are bubbles coming out of the inner nozzle 1; when the inner nozzle 1, the hexagon 5, and the AB seat are immersed in water, there should be no bubbles within 1 minute;

[0043] d. Connect liquid with a pressure of 6KG, and observe whether there is liquid leakage at the joint 2 of the liquid pipe;

[0044] e. Spraying test: Check the working status of the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com