Furniture hinge

A furniture and hinge technology, applied in the field of furniture hinges, can solve the problems of small joint surface and low installation height of the cover plate, and achieve the effect of easy access

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

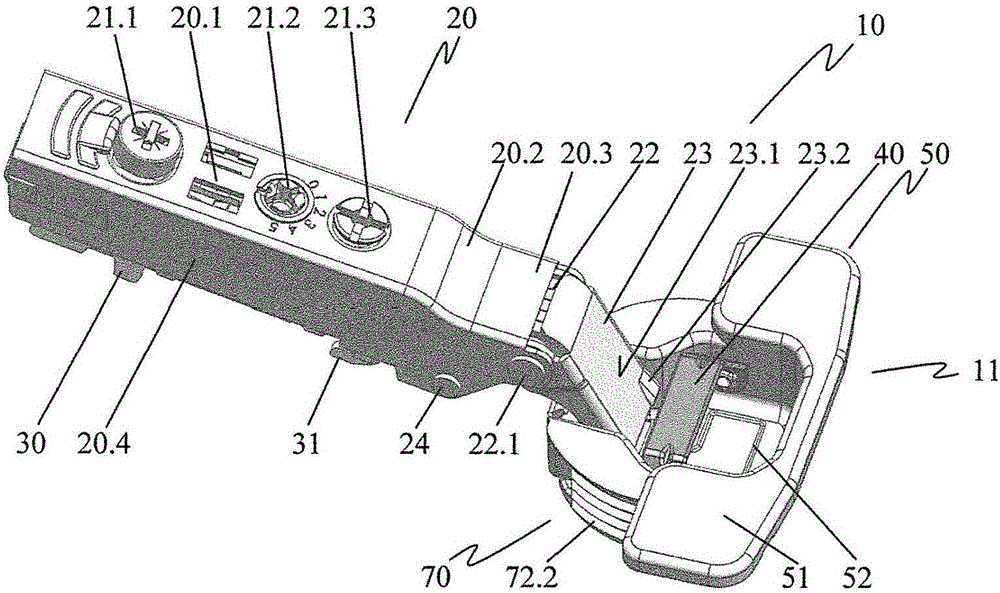

[0030] figure 1 The furniture hinge 10 is shown in a front perspective view in a first position of the actuating element 40 of the raised arrangement.

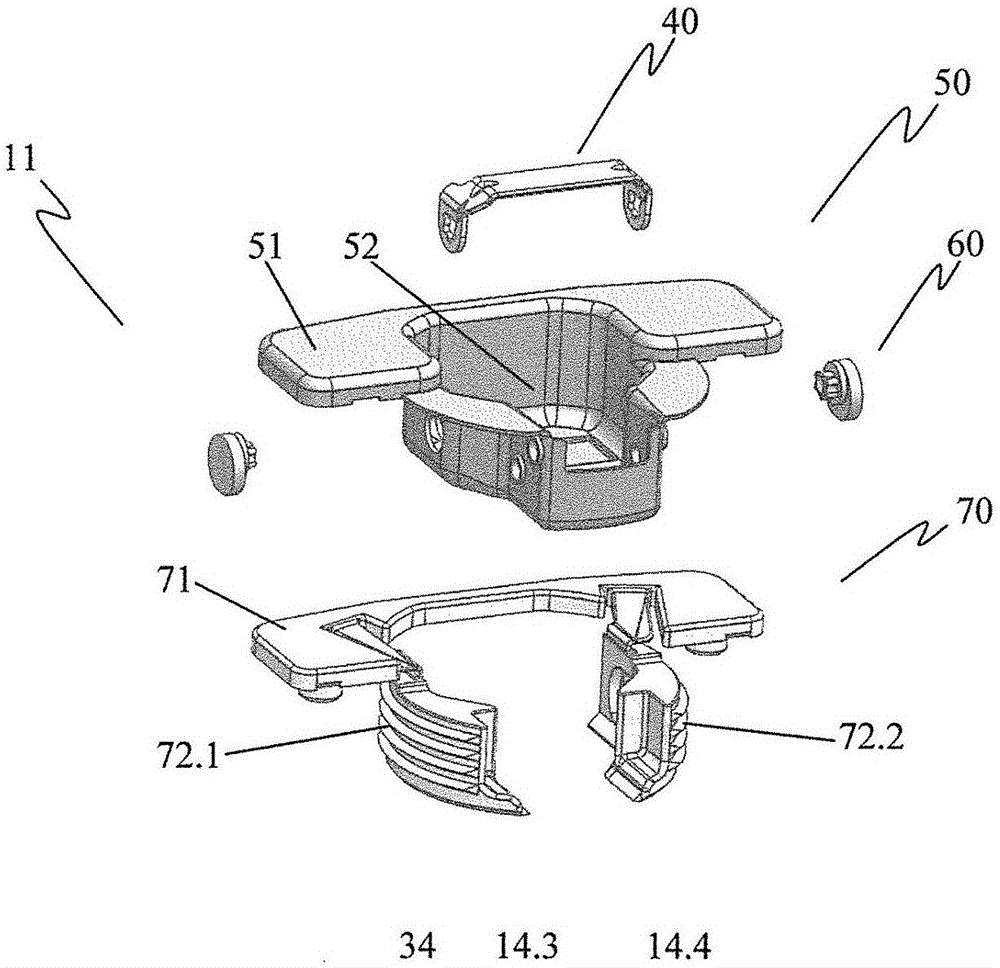

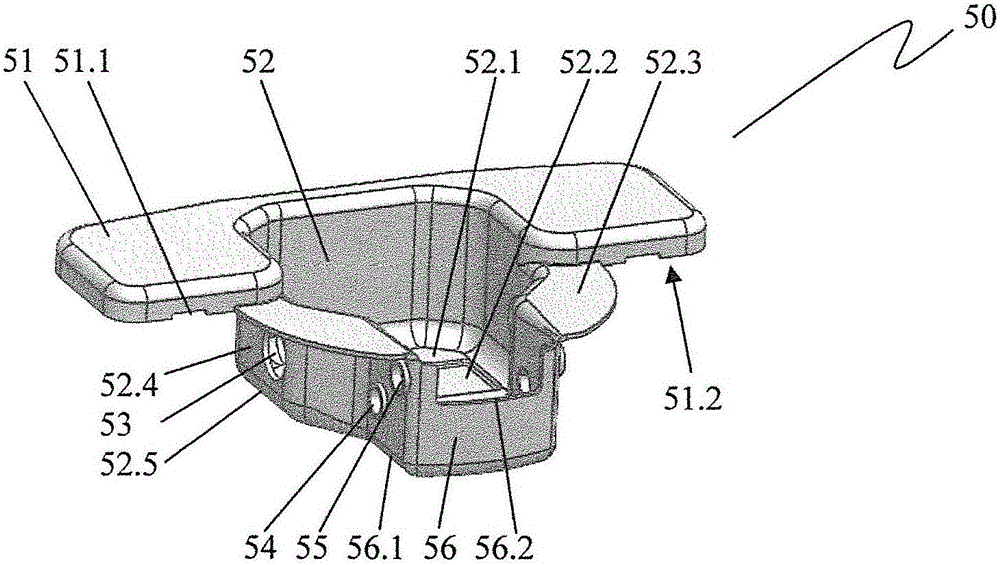

[0031]A hinge arm 20 and a stop 11 are associated with the furniture hinge 10 . The hinge arm 20 is connected to the stop 11 via a joint. Along the rear span 20.1 of the hinged arm 20 are arranged a depth adjustment screw 21.1, a positioner 21.2 and a support adjustment screw 21.3. The side legs 20.4 are connected to the rear span 20.1 on both sides. The hinge arm 20 is engaged in a connecting piece 30 comprising a connecting hook 31 . Towards the joint, the rear crotch 20.1 transitions via a transition section 20.2 into a section 20.3 which is concave relative to the rear crotch 20.1. The female section 20.3 is connected via the outer articulation 22 to the outer hinge lever 23, which comprises an actuation surface 23.1 with a protrusion 23.2 oriented towards the hinge cup 52 with the actuation piece 40. The outer articu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com