A two-mode automatic grinding machine

A grinding machine and two-mode technology, which is applied in the direction of grinding frame, grinding machine parts, grinding slides, etc., can solve the problems of grinding machine function and single grinding form, and achieve convenient and focused grinding processing , the effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

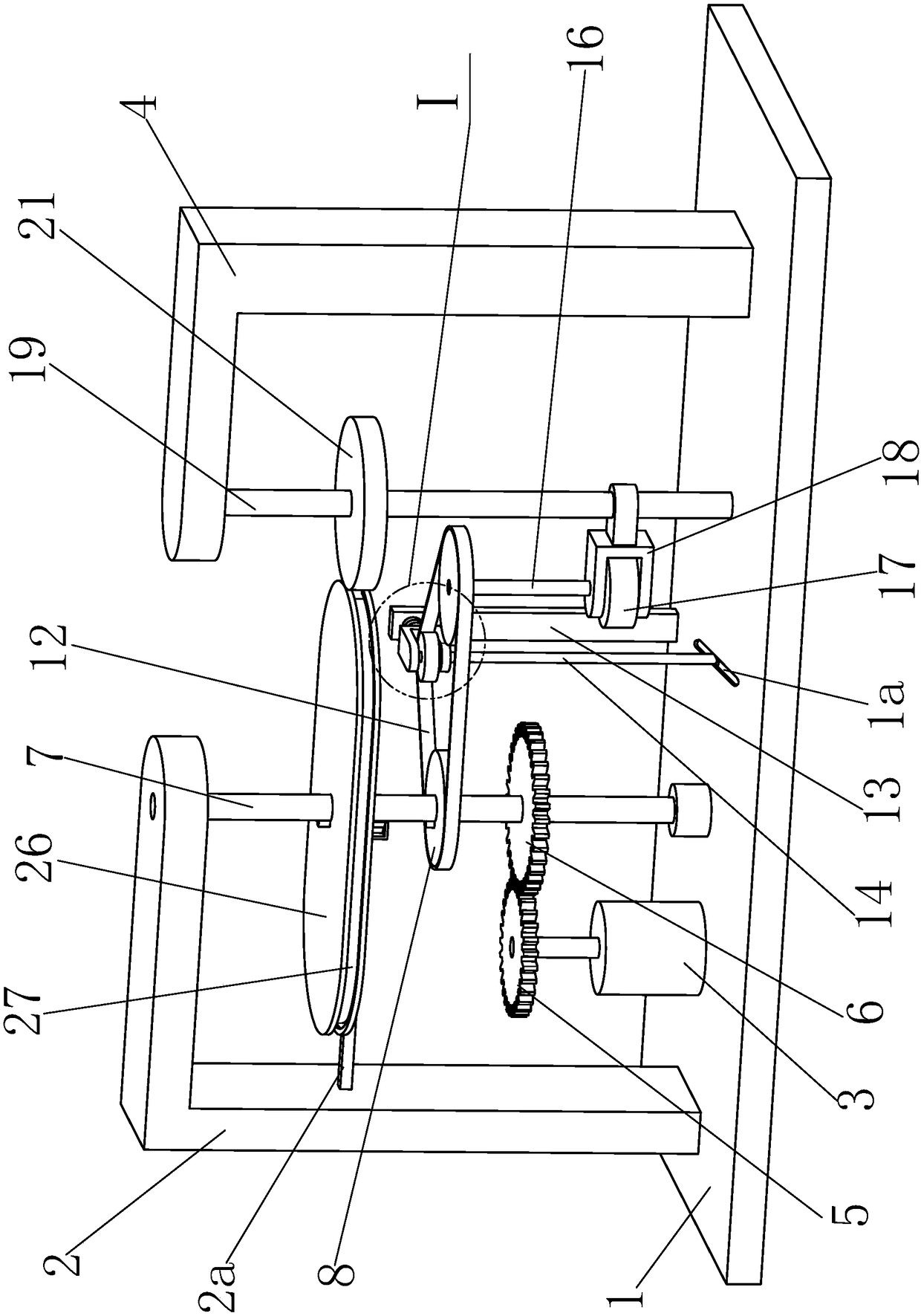

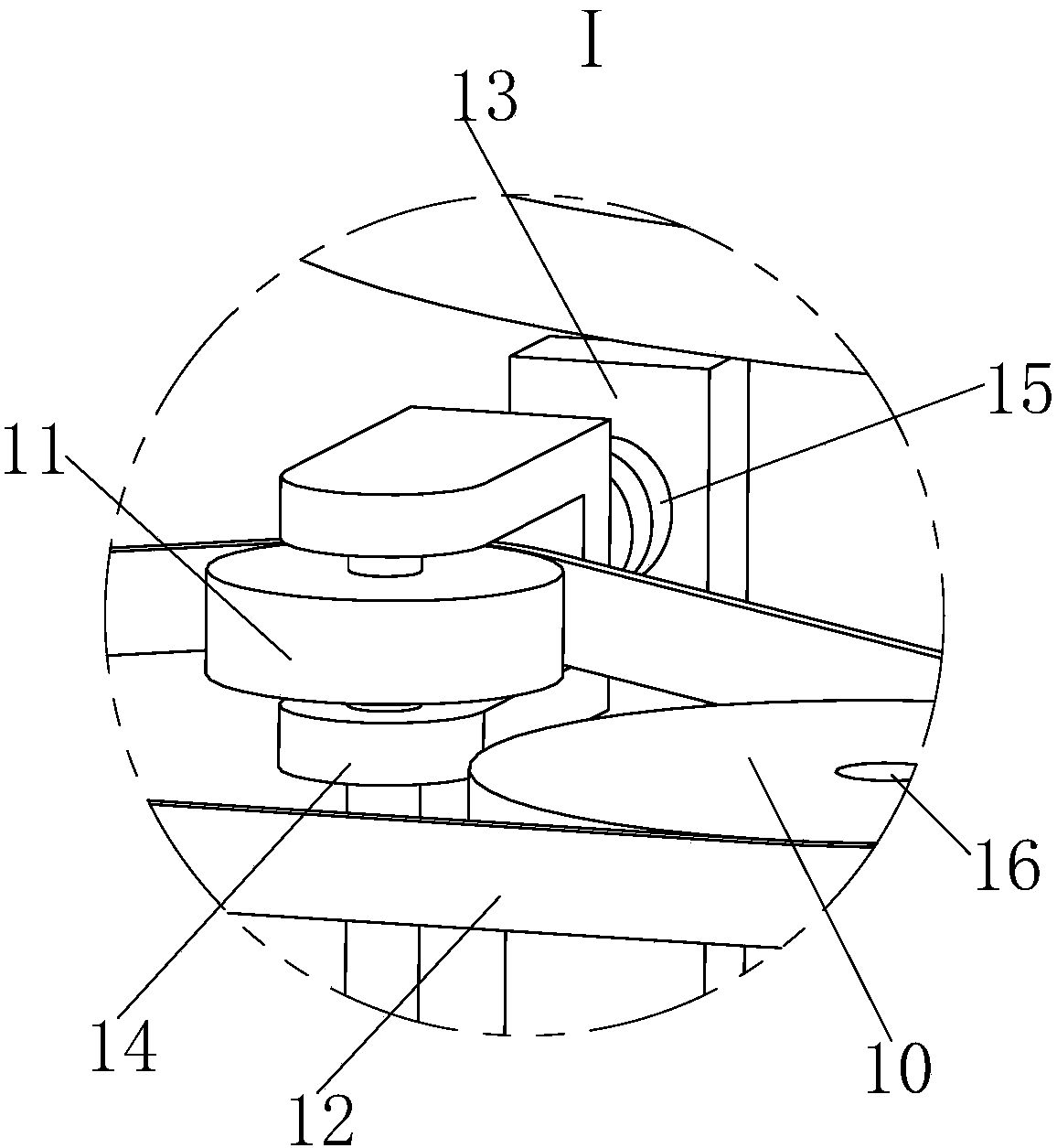

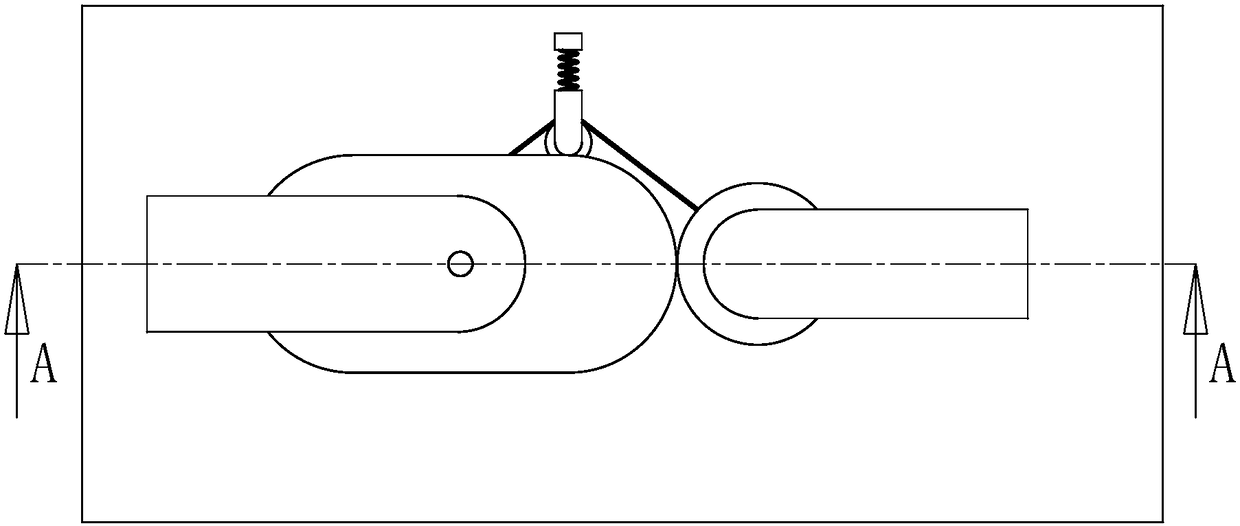

[0036] As the first embodiment of the present invention, that is, when the movable keys 29 are all pushed up by the push-up cylinder 30 to the top of the long keyway 7a, the elongated wheels 26 are all stationary, and the transmission of the belt 12 causes the rotating shaft 16 and Grinding wheel 17 all starts to rotate, can realize automatic grinding function.

[0037] As the second embodiment of the present invention, only the movable key 29 is pushed to the bottom of the long keyway 7a to cooperate with the short keyway 28. When the main shaft 7 rotates, on the one hand, the grinding wheel 17 can be rotated to realize the automatic grinding function. On the other hand, it can also drive the elongated wheel 26 to rotate. When the arc slider 22 slides in the corresponding area of the two straight line contours in the arc ring groove 27, the follower shaft 19 and the grinding wheel 17 will move in the horizontal direction. Slip to the left or right; when the arc slider 22 sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com