Converter station firewall construction technology

A construction technology, firewall technology, applied in the direction of walls, formwork/formwork/work frame, building components, etc., to achieve the effect of dense and smooth surface, consistent color, and sharp edges and corners

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

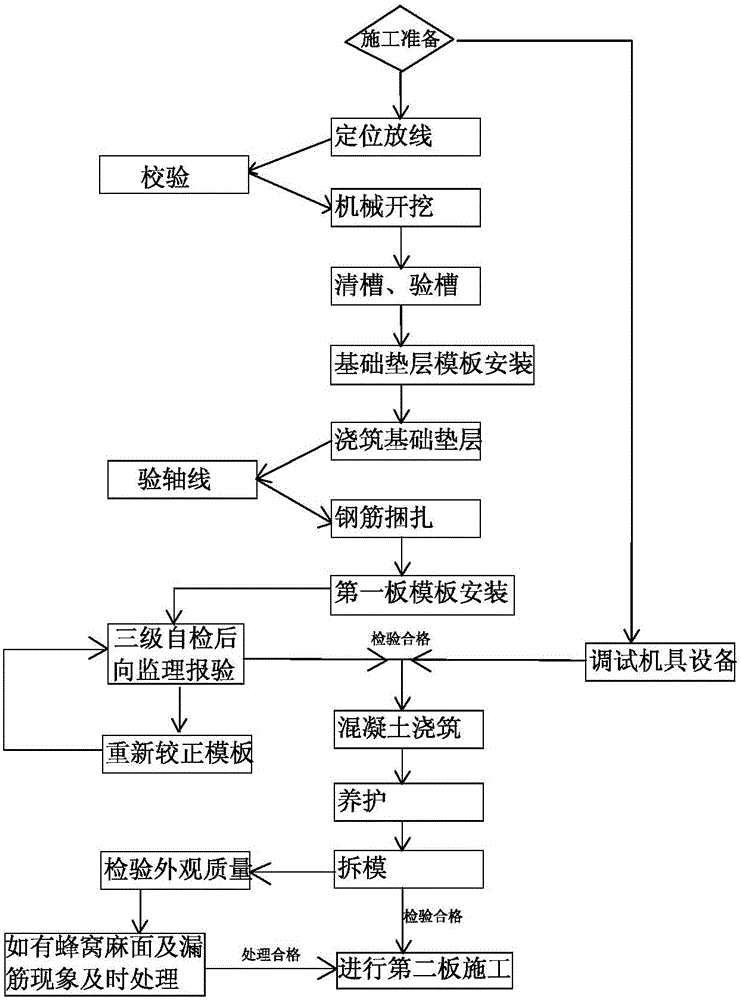

[0046] A construction process for a converter station firewall, comprising the following steps, such as figure 1 Shown:

[0047] 1. Construction preparation

[0048] 1. Technical preparation

[0049] (1) Before construction, according to the design drawings and the self-compacting concrete firewall design scheme, carry out the construction design and typesetting of the concrete firewall.

[0050] (2) Prepare a special self-compacting clear water firewall construction plan, and make technical and safety disclosures.

[0051] (3) The construction personnel shall receive special technical training and obtain qualifications for employment.

[0052] 2. Material preparation

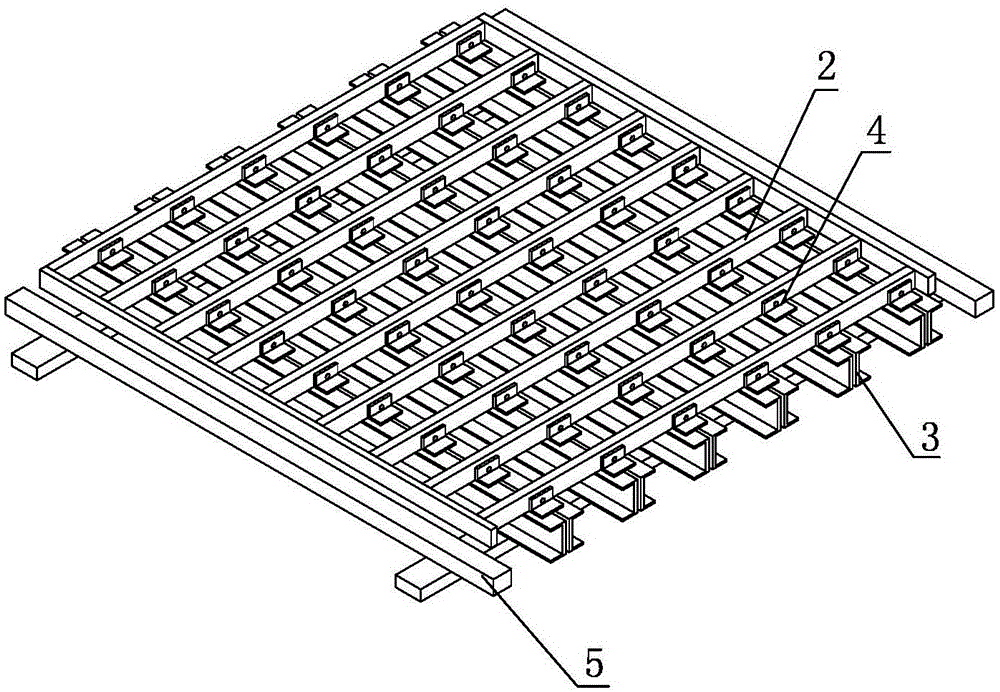

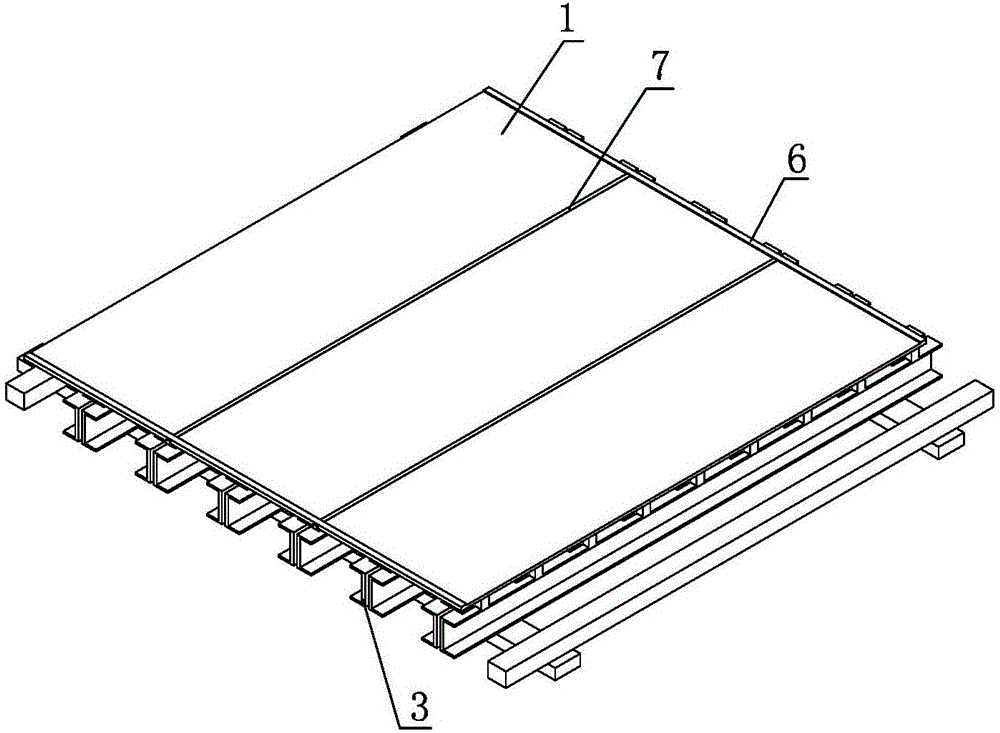

[0053] The configuration of construction materials is complete, including self-compacting concrete, formwork, formwork support frame and other materials used for engineering entities, which have been prepared and passed the inspection.

[0054] (1) Self-compacting concrete

[0055] The firewall is poured ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com