Slowly-lift cleaning frame

A technology for cleaning racks and lifting racks, which is applied in the field of cleaning racks, and can solve problems such as liquid level disturbance, liquid level interference, and affecting the quality of finished silicon wafers, and achieve the effect of improving stability and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

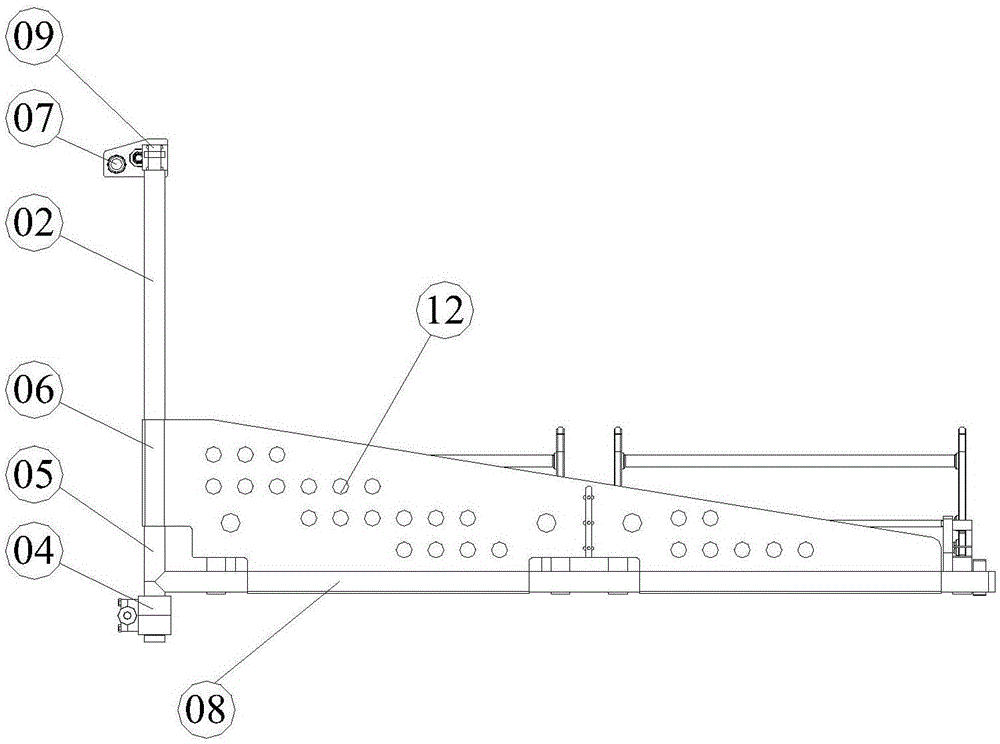

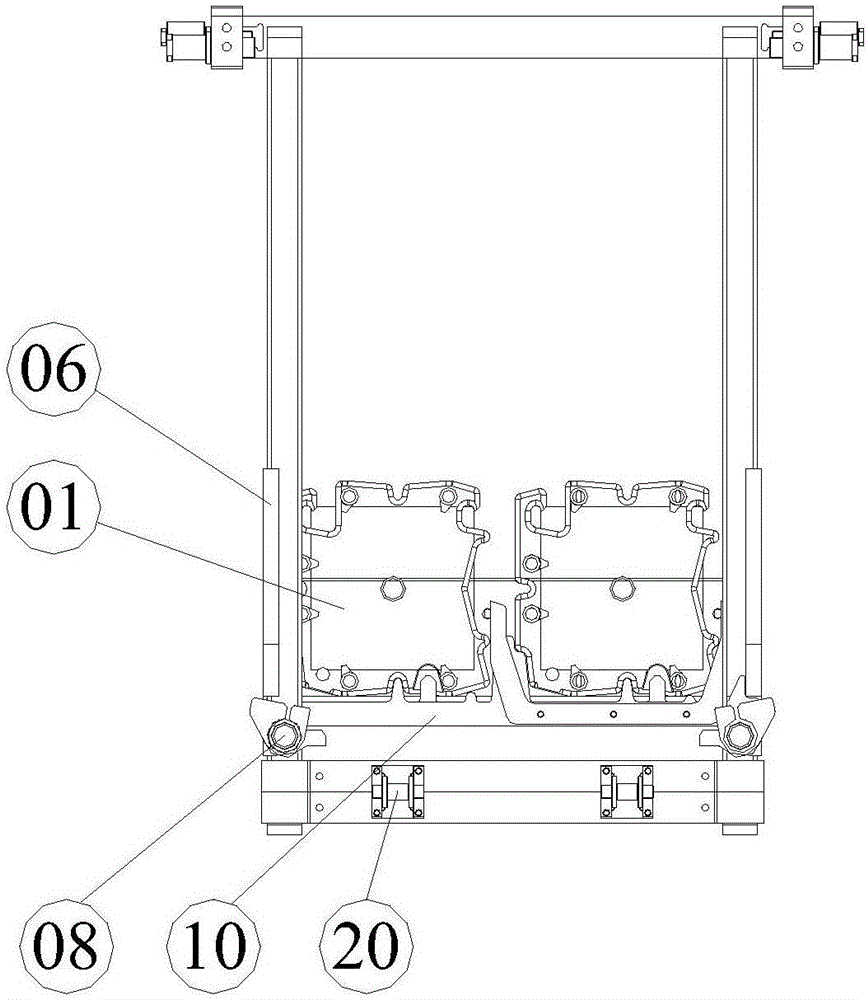

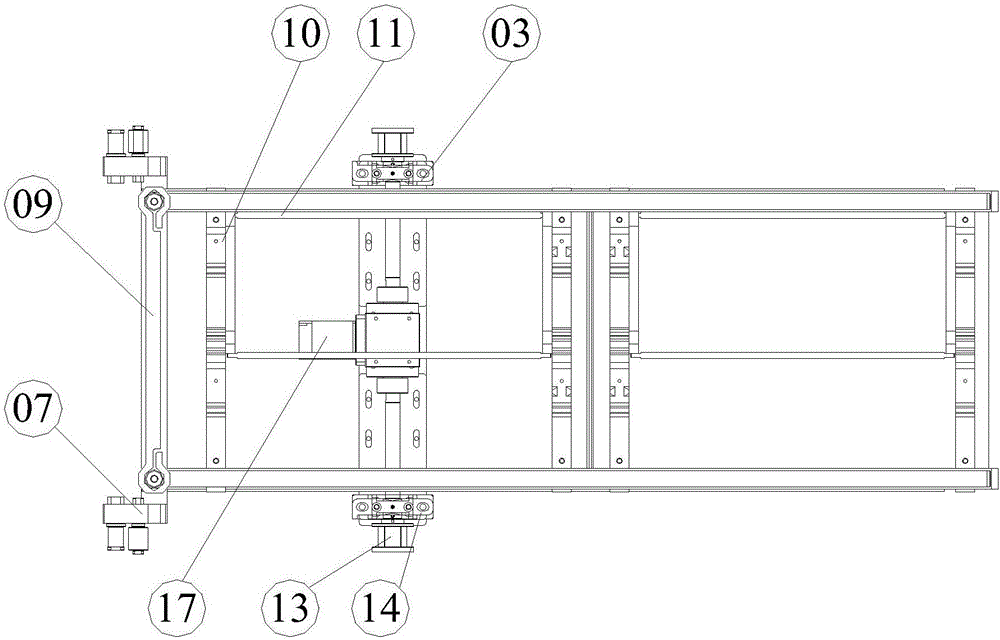

[0021] As shown in the figure, a slowly lifting cleaning frame includes a lifting frame 2, a motor assembly 3 located below the lifting frame, and a product box 1; the lifting frame 2 is located below the product box 1, carrying The product cassette 1 is used as a moving body; the motor assembly 3 is located below the lifting frame 2 and is connected to the lifting frame 2 through crawlers to provide the power required for lifting.

[0022] The lifting frame 2 includes a moving base plate 4, a lifting slide rail 5, a sliding guard plate 6, a lifting pulley 7, a limiting top plate 9, a limiting base plate 8, a longitudinal base plate 10 and a transverse base plate 11; the moving base plate 4 is located at The bottom of the lifting frame 2 is in conflict with the limit base plate 8, and is lifted or lowered by crawler belt pulling to drive the entire lifting frame 2 to rise or fall; the lifting slide rail 5 runs through vertically The moving bottom plate 4 is matched with the mo...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap