Double-printing head capable of being detached quickly and 3D (three-dimensional) printing machine with double-printing head

A technology of dual print heads and print heads, applied in coating devices, additive processing, etc., can solve the problems of slow speed and complicated disassembly process of print heads, and achieve the effect of solving complex disassembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

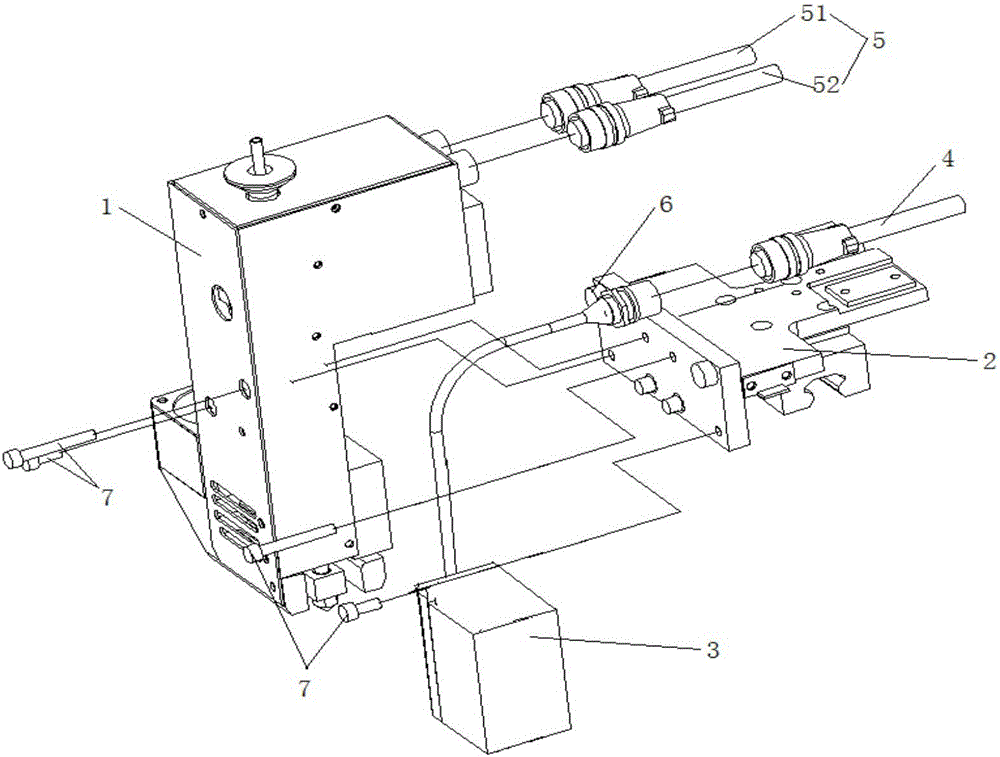

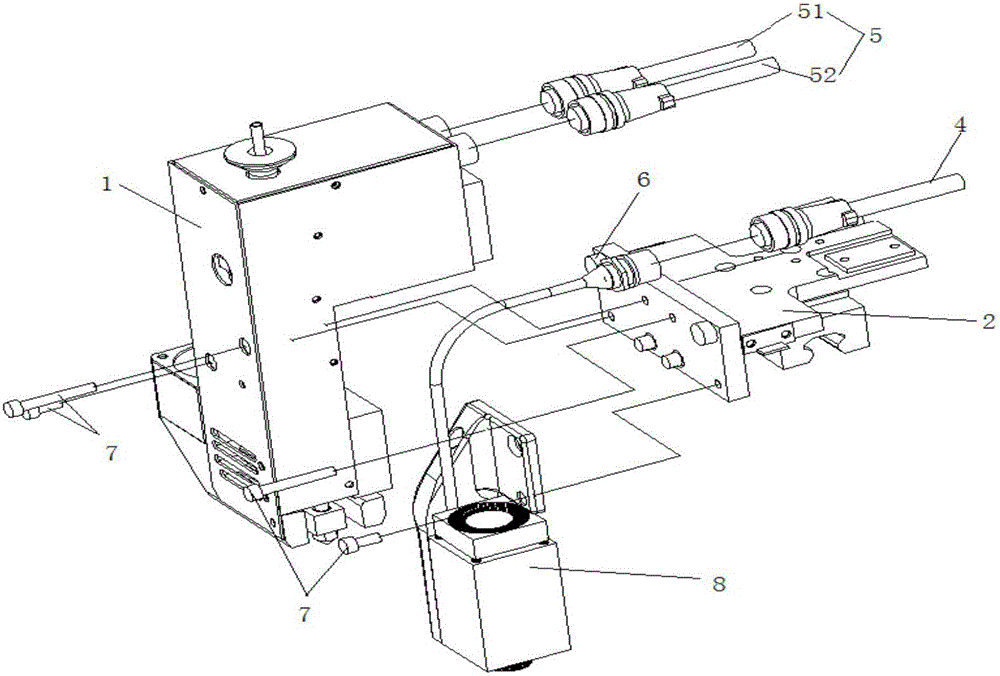

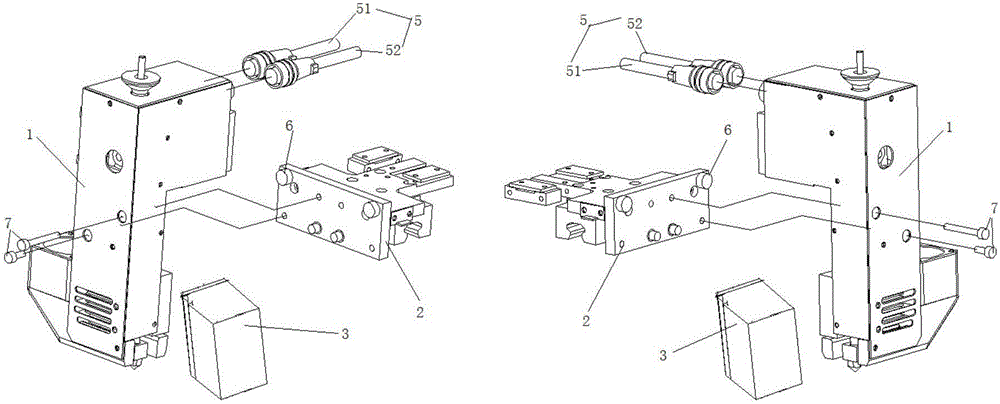

[0031] Embodiments of the present invention provide a quick detachable double print head, such as figure 2 As shown, it includes a pair of print heads 1 arranged opposite to each other. The print head 1 is an inverted L-shaped structure. The front and rear sides of the print head 1 are respectively provided with a fixing seat 2 and a laser engraving head 8. The printing head 1 and the fixing seat 2 It is connected with the laser engraving head 8 through the first quick release aviation joint assembly 4, and the upper side of the print head 1 is connected with the printer body through the second quick release aviation joint assembly 5, so that when the print head breaks down, The first quick-release aviation joint assembly 4 and the second quick-release aviation joint assembly 5 can be quickly disassembled, which solves the problem of complicated and slow disassembly process of the existing printing head.

[0032] The side of the fixing seat 2 near the print head 1 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com